Have you ever wondered how HVAC technicians are able to detect and fix leaks in your heating, ventilation, and air conditioning system? Well, the process might be more straightforward than you think. HVAC techs utilize a combination of specialized tools and techniques to effectively pinpoint leaks and ensure your system is running efficiently. From using ultraviolet dyes to advanced leak detectors, these skilled professionals have the know-how to identify and repair any potential leaks that could be causing issues with your HVAC system. So, let’s take a closer look at how HVAC techs check for leaks and keep your home comfortable year-round.

Visual Inspection

Checking for Obvious Signs

During a visual inspection, HVAC technicians carefully examine the system to look for any obvious signs of leaks. This includes inspecting all visible components such as pipes, ductwork, valves, fittings, and connections. They check for signs of corrosion, rust, condensation, or water puddles around these areas, as they can indicate a leak. Additionally, technicians also inspect for any loose or damaged components that may contribute to leakage.

Inspecting Equipment

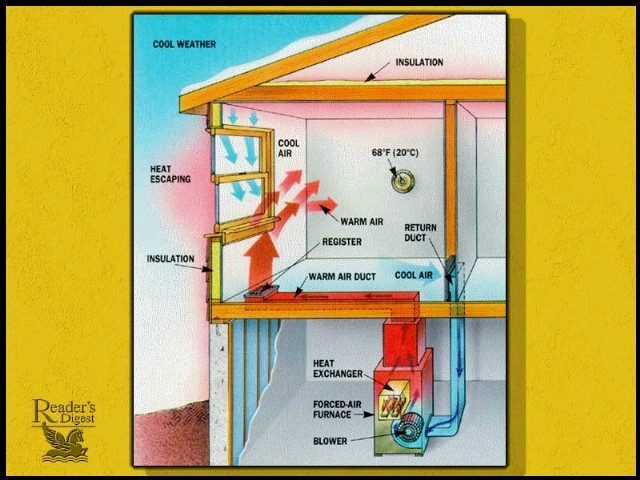

HVAC technicians thoroughly inspect all equipment associated with the system to identify potential leaks. This includes examining the air conditioner, heat pump, furnace, or any other relevant appliances. They look for signs of wear, cracks, or damage in the equipment, particularly around areas that may house refrigerant or coolant lines. By inspecting the inner components of the equipment, technicians can detect leaks that may not be visible externally.

Examining Ductwork

Ductwork plays a crucial role in delivering conditioned air throughout the building. HVAC technicians check for leaks in the ductwork by visually inspecting the joints, connections, and seams. They look for signs of wear, detachment, or gaps that could allow air or refrigerant to escape. Technicians also examine insulation around the ductwork, ensuring it is properly installed and sealed to prevent leakage. Any identified leaks in the ductwork will be noted for further investigation and repair.

Investigating Piping

Piping is another important component of an HVAC system that requires thorough inspection for leaks. HVAC technicians carefully examine refrigerant lines, water pipes, or any other relevant piping for visible signs of leaks. They check for cracks, corrosion, or loose connections. Technicians may also use specialized tools to pressurize the system and observe for any visible leaks along the piping. Identifying and addressing leaks in the piping is essential for maintaining the efficiency and functionality of the HVAC system.

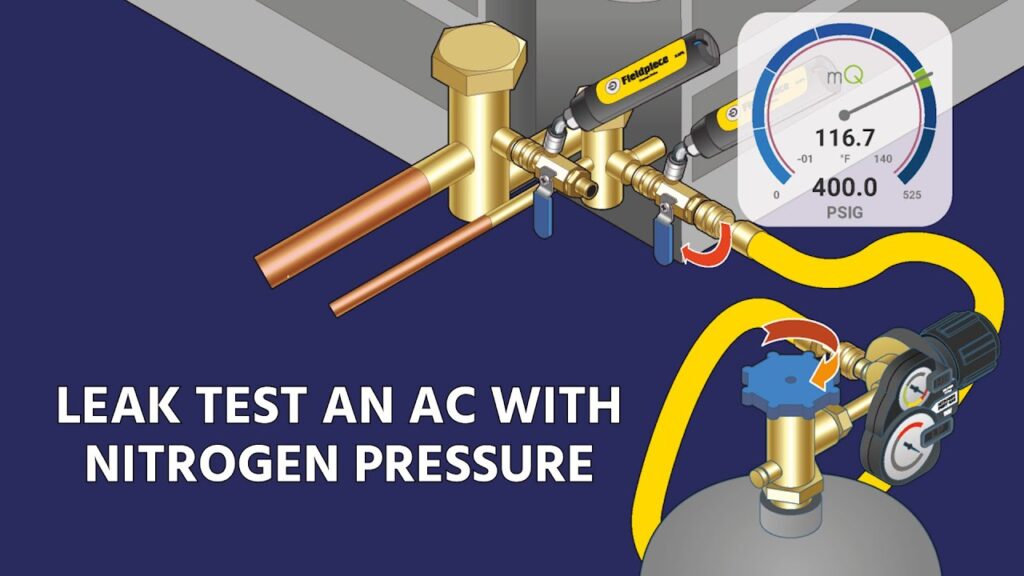

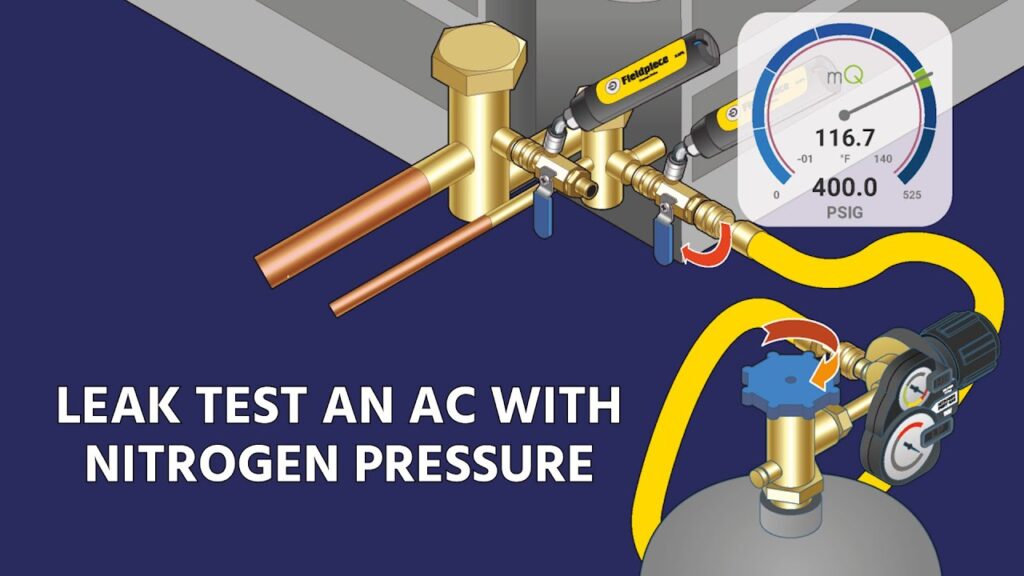

Using Pressure Testing

Pressurizing the System

Pressure testing is a widely used method by HVAC technicians to check for leaks in an HVAC system. The first step in this process involves pressurizing the system with compressed air or nitrogen. By introducing pressurized air into the system, technicians can effectively identify leaks by observing pressure drops or fluctuations.

Monitoring Pressure Drop

After pressurizing the system, HVAC technicians closely monitor the pressure to detect any significant drop over a period of time. If the pressure drops rapidly or continuously, it indicates the presence of a leak. Technicians may use pressure gauges or digital manometers to accurately measure and monitor the pressure inside the system. This information helps them determine the location and severity of the leak.

Using Specialized Tools

In addition to monitoring pressure drop, HVAC technicians utilize specialized tools to assist in pressure testing and leak detection. These tools may include ultrasonic leak detectors, electronic leak detectors, or refrigerant leak detectors. These instruments enable technicians to pinpoint the exact location of the leak, whether it is in the ductwork, piping, or equipment. By combining pressure testing with these specialized tools, HVAC technicians can efficiently identify and address leaks in the system.

Smoke Testing

Introducing Smoke into the System

Smoke testing is a method that involves introducing a controlled amount of smoke or vapor into the HVAC system. HVAC technicians inject the smoke into the system through a smoke generator or smoke machine, which disperses the smoke throughout the system. The smoke travels along the airflow, highlighting any areas where leaks may be present.

Observing Smoke Divergence

As the smoke is introduced into the HVAC system, technicians carefully observe the movements and behavior of the smoke. If there is a leak, the smoke will diverge, escaping from the system at the point of leakage. HVAC technicians pay close attention to the areas where the smoke diverges or escapes, as this indicates the location of a leak. This method is particularly effective for identifying leaks in ductwork or other hard-to-reach areas of the system.

Identifying Leaks

Through smoke testing, HVAC technicians can accurately identify the location of leaks in the HVAC system. By following the path of the escaping smoke, they can pinpoint the exact area where leaks are occurring. Once the leaks are identified, technicians can proceed with repairs or sealing the affected areas. Smoke testing is a valuable method in detecting leaks, especially in situations where other methods may not be as effective.

Thermal Imaging

Using an Infrared Camera

Thermal imaging is a non-intrusive method used by HVAC technicians to detect leaks in the system. It involves using an infrared camera, which can detect variations in temperature. This technology allows technicians to identify temperature differences in different parts of the system, indicating potential areas of leakage.

Detecting Temperature Variations

With the help of an infrared camera, HVAC technicians scan the HVAC system to detect temperature variations. If there is a leak, the escaping refrigerant or coolant will cause a noticeable temperature variation in the surrounding area. The infrared camera can capture these variations as different colors or patterns, making it easy to identify potential leakage points.

Locating Potential Leaks

By analyzing the captured thermal images, HVAC technicians can locate potential leak points in the system. The areas showing significant temperature variations or anomalies provide valuable insights into possible leakage spots. Technicians can then focus on these areas for further inspection and initiate necessary repairs or sealing to prevent further leakage and maintain system efficiency.

Ultraviolet Dye Testing

Adding Fluorescent Dye

Ultraviolet (UV) dye testing involves adding a small amount of fluorescent dye to the HVAC system. HVAC technicians inject the dye into the system, and it circulates along with the refrigerant or coolant. The dye remains invisible under normal conditions but becomes visible under UV light, making it easier to identify leaks.

Illuminating with UV Light

After adding the fluorescent dye, HVAC technicians use a UV light source to illuminate the system. When the UV light shines on the dye, it fluoresces, allowing technicians to see the exact location of leaks. This method is particularly effective for identifying small leaks that may not be easily visible otherwise.

Spotting Leaks with Fluorescence

By examining the illuminated system under UV light, HVAC technicians can easily spot leaks as the fluorescent dye reveals their exact location. The intensity of the fluorescence indicates the severity of the leak. Technicians can then proceed to repair or seal the affected areas to prevent further leakage. UV dye testing is a reliable method for pinpointing leaks, especially in intricate or hard-to-reach parts of the HVAC system.

Electronic Leak Detection

Using Electronic Leak Detectors

Electronic leak detection involves the use of specialized electronic devices designed to detect refrigerant leaks. These devices can sense the presence of refrigerant gases in the air, allowing HVAC technicians to locate the source of leakage accurately. Electronic leak detectors are highly sensitive and can detect even minor leaks that may not be visible or detectable through other methods.

Sensing Refrigerant Leaks

HVAC technicians use electronic leak detectors to scan the HVAC system for the presence of refrigerant leaks. The detector alerts the technician with an audible alarm or visual display if it senses leaking refrigerant. Technicians carefully move the detector along various components, such as joints, fittings, valves, or connections, to identify the specific areas where leaks are occurring.

Locating Hidden Leaks

Electronic leak detectors are particularly useful in locating hidden leaks within the HVAC system. They can reach areas that may be challenging to access visually and quickly identify leakage points. By using electronic leak detectors, HVAC technicians can efficiently locate and address leaks, ensuring the system operates at optimal efficiency and minimizing the loss of refrigerant.

Bubbling Solutions

Applying Bubble Solutions

Bubbling solutions are a simple yet effective method for identifying leaks in an HVAC system. HVAC technicians apply a specially formulated bubble solution to the areas suspected of having leaks. The solution, when applied to a leak, creates visible bubbles due to escaping gas or liquid.

Observing Bubble Formation

After applying the bubble solution, HVAC technicians carefully observe the areas for the formation of bubbles. If there is a leak, the escaping gas or liquid causes the bubble solution to bubble up, revealing the location of the leak. Technicians closely watch for bubble formation, paying attention to the size and frequency of the bubbles to assess the severity of the leak.

Identifying Leak Locations

By observing bubble formation, HVAC technicians can accurately identify the locations of leaks within the system. This method is especially effective for detecting leaks in piping, valves, or fittings. Once the leaks are identified, technicians can proceed to repair or replace the affected components, ensuring the system operates efficiently and minimizing the potential for further leakage.

Pressure Decay Testing

Pressurizing the System

Pressure decay testing is another method that involves pressurizing the HVAC system. HVAC technicians pressurize the system by introducing compressed air or nitrogen and sealing it. This step allows them to create a controlled and stable pressure within the system before monitoring for any pressure decay.

Monitoring Pressure Decay Rate

Once the system is pressurized, HVAC technicians carefully monitor the pressure for any signs of decay. If there is a leak, the pressure within the system will drop over time. Technicians use pressure gauges or digital manometers to accurately measure and monitor the pressure decay rate. By analyzing the rate of decay, they can ascertain the location and severity of the leak.

Determining Leakage Points

By measuring the pressure decay rate, HVAC technicians can determine the specific areas where leakage is occurring within the HVAC system. This information guides them in focusing their inspection efforts on the identified areas. Once the leakage points are determined, technicians can proceed with necessary repairs or sealing to rectify the leaks and restore the system’s efficiency.

Dye Injection

Injecting Fluorescent Dye

Similar to UV dye testing, dye injection involves injecting a fluorescent dye into the HVAC system. HVAC technicians add the dye, which circulates along with the refrigerant or coolant. The dye remains invisible under normal conditions but becomes visible when exposed to UV light.

Inspecting Components with UV Light

After injecting the fluorescent dye, HVAC technicians inspect the system with the assistance of UV light. When the UV light shines on the dye, it fluoresces, allowing technicians to identify leaks accurately. By examining various components, such as joints, valves, or connections, under UV light, technicians can spot any dye traces, indicating the presence of a leak.

Spotting Leaks with Dye Traces

The fluorescent dye traces illuminated by UV light enable HVAC technicians to precisely locate leaks within the system. The intensity of the fluorescence indicates the severity of the leak, helping technicians prioritize repairs or sealing activities. Dye injection is a reliable method for identifying leaks, especially in complex systems with multiple components.

Listening for Refrigerant Leaks

Using Ultrasonic Detectors

Listening for refrigerant leaks involves utilizing ultrasonic detectors to identify high-frequency sounds produced by the escaping refrigerant. These detectors are highly sensitive and pick up sounds that are beyond the range of human hearing. The ultrasonic detector amplifies and converts these sounds to an audible range for technicians to hear.

Detecting High-Frequency Sounds

HVAC technicians use the ultrasonic detectors to scan the HVAC system for any high-frequency sounds that may indicate refrigerant leaks. These leaks often produce distinct sounds, such as hissing or whistling, which can be detected by the ultrasonic detectors. Technicians move the detector along various components, such as joints, fittings, valves, or connections, to identify the specific areas where leaks are occurring.

Pinpointing Leak Sources

By using ultrasonic detectors, HVAC technicians can pinpoint the exact sources of refrigerant leaks within the system. These detectors are particularly useful in identifying leaks in hard-to-reach or concealed areas. Once the leaks are located, technicians can take appropriate measures to repair or seal the affected components, ensuring the system operates efficiently and minimizing refrigerant loss.

In conclusion, HVAC technicians employ various methods to check for leaks in HVAC systems. Visual inspection, pressure testing, smoke testing, thermal imaging, ultraviolet dye testing, electronic leak detection, bubbling solutions, pressure decay testing, dye injection, and listening for refrigerant leaks are all effective techniques for identifying and locating leaks in different components of the system, such as ductwork, piping, and equipment. By utilizing these methods, HVAC technicians can ensure the efficient operation of the system, minimize environmental impact, and prolong the lifespan of the HVAC system.