Are you wondering how to determine if your fiberglass insulation is in need of replacement? Look no further, as this article aims to shed light on the telltale signs that indicate the deterioration of this common type of insulation. From reduced energy efficiency to the presence of mold, we will explore the key indicators that suggest it might be time to bid farewell to your current fiberglass insulation. So, if you have any doubts about the quality of your insulation, keep reading to discover the answers you seek.

What is Fiberglass Insulation?

Definition and Composition

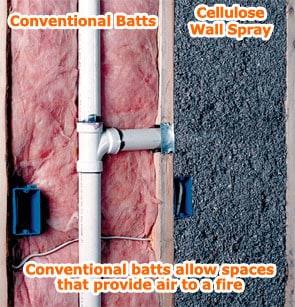

Fiberglass insulation is a commonly used material for insulating homes and buildings. It is made from tiny glass fibers that are woven together to form an insulating material. The fibers are usually made from recycled glass or sand, which is melted and spun into thin strands. These strands are then grouped together to create batts or rolls of insulation that can be easily installed in walls, ceilings, and floors.

The composition of fiberglass insulation allows it to trap air and create a barrier that prevents heat transfer. This helps to regulate the temperature inside a building, keeping it warm in the winter and cool in the summer. Fiberglass insulation is also known for its durability and resistance to pests, mold, and fire.

Benefits of Fiberglass Insulation

Energy Efficiency

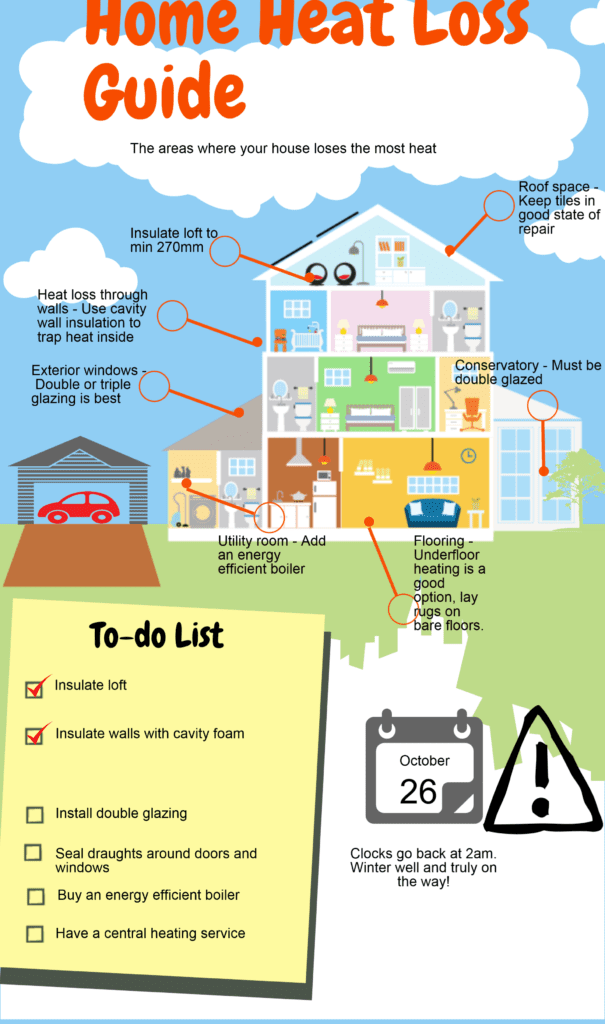

One of the main benefits of fiberglass insulation is its energy efficiency. By creating a barrier to heat transfer, it helps to reduce the amount of energy needed to heat or cool a building. This leads to lower energy bills and a more comfortable living environment. The thermal resistance of fiberglass insulation, known as R-value, can vary depending on the thickness and density of the material, allowing homeowners to choose the level of insulation that best suits their needs.

Cost-Effectiveness

In addition to its energy-saving properties, fiberglass insulation is also cost-effective. The material itself is relatively inexpensive compared to other types of insulation, making it an affordable option for homeowners. Furthermore, the installation process is straightforward and can often be done as a DIY project, saving on labor costs. This makes fiberglass insulation a cost-effective choice for both new construction and retrofitting existing buildings.

Fire Resistance

Fiberglass insulation is inherently fire-resistant, which is an important safety feature. Unlike other types of insulation that can easily catch fire and spread flames, fiberglass insulation does not burn. This can help to slow down the spread of fire and provide occupants with more time to escape. It is also worth noting that fiberglass insulation is not a significant source of toxic smoke when it does come into contact with flames.

Soundproofing

Another advantage of fiberglass insulation is its soundproofing capabilities. The dense fibers of the insulation material can absorb and dampen sound waves, reducing the transmission of noise between rooms. This is especially beneficial in multi-story homes or buildings, where soundproofing can help maintain privacy and create a quieter living or working environment.

Common Issues with Fiberglass Insulation

Moisture Absorption

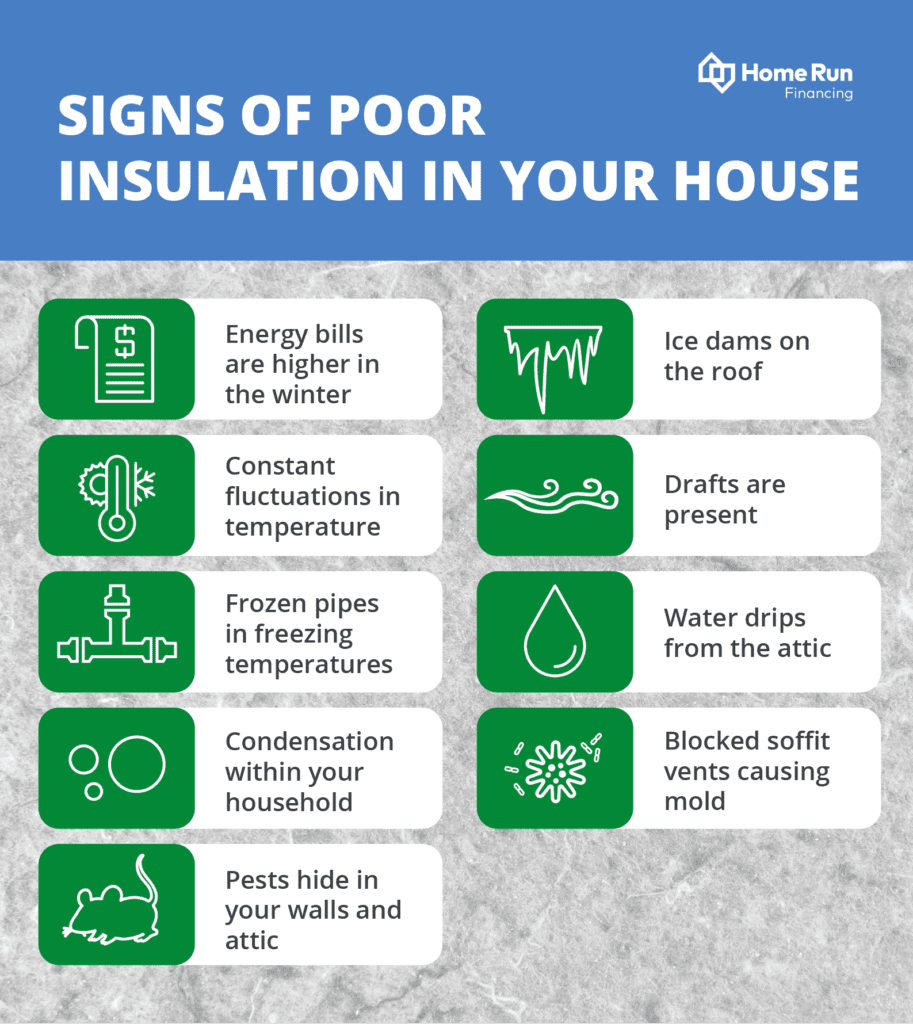

One of the most common issues with fiberglass insulation is moisture absorption. Fiberglass is a porous material, meaning it can absorb and retain moisture over time. This can lead to the insulation losing its effectiveness and potentially promoting the growth of mold or mildew. Moisture can enter the insulation through leaks in the building envelope or from condensation within the walls, ceilings, or floors.

Poor Installation

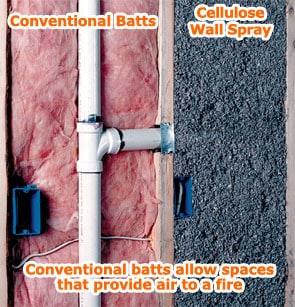

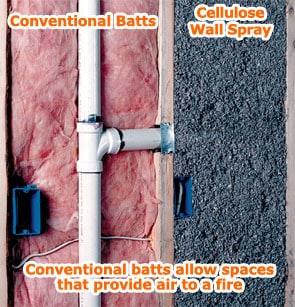

Improper installation is another common issue with fiberglass insulation. If the insulation is not installed correctly, gaps and voids can form, allowing air to bypass the insulation and reducing its overall effectiveness. These gaps can occur at the edges of the insulation, around electrical boxes, or where insulation batts are not tightly fitted together. Poor installation can also result in compression or overstuffing of the insulation, which can decrease its R-value and lead to performance issues.

Air Leakage

Air leakage is a problem that can affect any type of insulation, including fiberglass. If there are air leaks in the building envelope, such as gaps around windows, doors, or utility penetrations, air can flow in and out of the walls. This not only reduces the effectiveness of the insulation but also creates drafts and can cause discomfort for occupants. It is important to properly seal any air leaks before installing or replacing fiberglass insulation to ensure optimal performance.

Health Concerns

There have been some health concerns associated with fiberglass insulation, mainly related to the inhalation of fibers. While fiberglass insulation is considered safe when properly installed and not disturbed, fiberglass fibers can become airborne if the material is damaged, torn, or disturbed during renovations or repairs. Inhaling these fibers can cause irritation to the skin, eyes, and respiratory system. However, it is worth noting that fiberglass insulation manufacturers have made efforts to produce low-dust and low-irritation versions of the material to reduce these risks.

Signs of Problematic Fiberglass Insulation

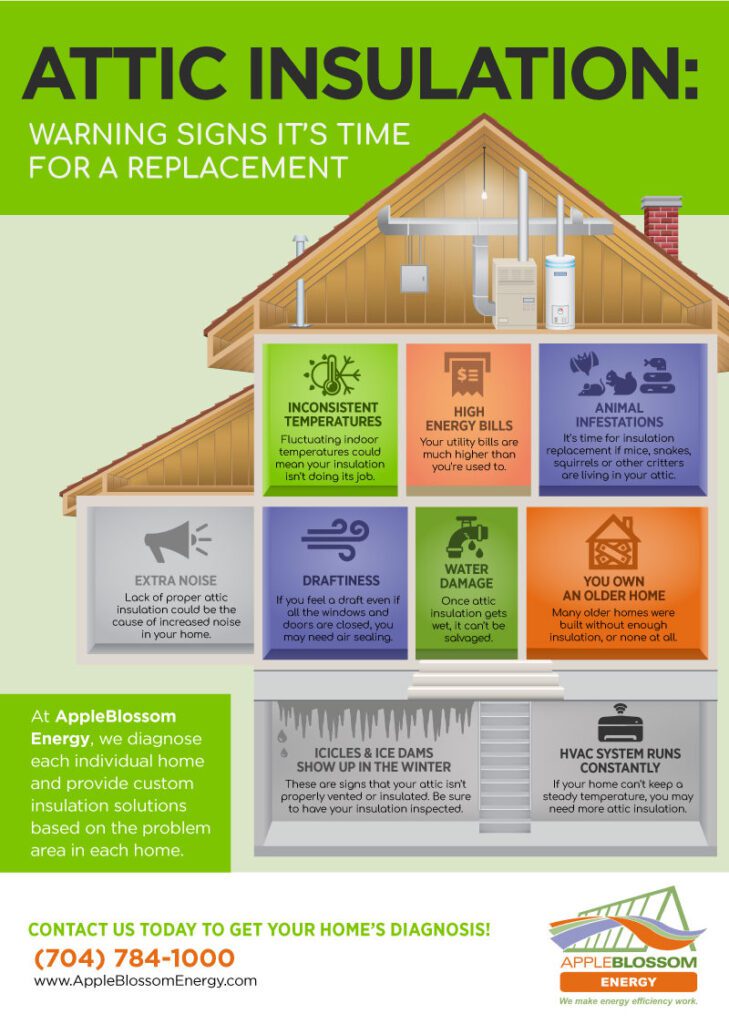

Visible Mold or Mildew

One of the most obvious signs of problematic fiberglass insulation is the presence of visible mold or mildew. If moisture has penetrated the insulation and is not properly addressed, it can create a conducive environment for mold and mildew growth. These fungi thrive in dark, damp areas and can pose health risks to occupants. If mold or mildew is visible on the surface of the insulation, it is important to address the issue promptly to prevent further damage and potential health concerns.

Unpleasant Odors

Unpleasant odors can also be a sign of problematic fiberglass insulation. If moisture or mold growth is present, it can result in musty or stale odors emanating from the insulation. These odors can permeate the living space and indicate a potential issue with the insulation. If you notice persistent unpleasant odors, it is recommended to investigate the source and address it accordingly.

Increased Energy Bills

A sudden increase in energy bills can be an indication that there is a problem with your fiberglass insulation. If the insulation is damaged, improperly installed, or there are air leaks, it can result in the loss of heated or cooled air, leading to increased energy consumption. Monitoring your energy bills and comparing them to previous months can help you identify any significant spikes that may be caused by insulation issues.

Uneven Temperature Distribution

If you notice significant temperature differences between different areas of your home or building, it may be a sign of problematic fiberglass insulation. Poorly installed insulation or insulation with gaps and voids can allow air to pass through, resulting in uneven temperature distribution. Some rooms may feel much colder or hotter than others, making it uncomfortable for occupants. If you experience significant temperature variations, it is worth considering an inspection of your insulation.

Testing Fiberglass Insulation

Moisture Testing

To determine if fiberglass insulation has moisture-related issues, moisture testing can be conducted. This involves using moisture meters or similar devices to measure moisture levels within the insulation. If high levels of moisture are detected, it indicates that there may be a problem with the insulation’s ability to resist moisture or that there are moisture sources that need to be addressed.

Thermal Imaging

Thermal imaging, also known as infrared imaging, can be used to identify insulation issues such as air leaks or poor installation. This non-contact diagnostic tool captures the temperature variations on surfaces, allowing professionals to detect temperature anomalies that may indicate insulation problems. By using thermal imaging, hidden gaps, voids, or areas of compressed insulation can be detected, providing valuable information for insulation assessment.

Air Leakage Testing

Air leakage testing, such as a blower door test, can help determine if there are air leaks in the building envelope that are affecting the performance of the fiberglass insulation. This test involves creating a pressure differential between the inside and outside of the building and measuring the air leakage rate. By identifying and sealing air leaks, the insulation’s effectiveness can be enhanced, and energy efficiency improved.

Indoor Air Quality Testing

Indoor air quality testing can be conducted to assess if fiberglass insulation is contributing to any health concerns. This testing involves sampling and analyzing the air for potential contaminants, including volatile organic compounds (VOCs) and airborne particles. By assessing the indoor air quality, any potential issues related to fiberglass insulation, such as the presence of fiberglass fibers, can be identified and appropriate actions taken.

DIY Inspection of Fiberglass Insulation

Examine Visible Areas

As a homeowner, you can perform a visual inspection of the visible areas where fiberglass insulation is installed. Look for any signs of damage, such as tears, compression, or disintegration. Check for areas where the insulation may have been improperly installed, leaving gaps or voids. Examine the edges and corners of the insulation to ensure a tight and uniform fit.

Check for Moisture Damage

Inspecting for moisture damage is crucial in determining the condition of fiberglass insulation. Look for any staining, discoloration, or watermarks on the insulation or nearby surfaces, as these can be indicators of moisture intrusion. Use a moisture meter or similar device to check the moisture levels in the insulation. If high levels of moisture are detected, further investigation and remediation may be required.

Inspect for Gaps and Gaps

Carefully inspect the insulation for any gaps, voids, or areas where the insulation is not properly fitted together. These gaps can allow air to bypass the insulation, reducing its effectiveness. Pay special attention to areas around electrical boxes, pipes, and utility penetrations where insulation may be improperly installed or missing entirely. Use your hand to feel for any drafts around these areas, indicating potential air leaks.

Monitor Energy Consumption

Monitoring your energy consumption can provide valuable insights into the performance of your fiberglass insulation. Keep track of your energy bills and compare them to previous years or months. Significant increases in energy consumption may indicate insulation issues, such as gaps, voids, or air leaks. By monitoring your energy consumption, you can identify patterns or changes that may warrant further investigation or insulation improvements.

Professional Inspection and Maintenance

Hiring an Insulation Contractor

For a thorough inspection of your fiberglass insulation, it is advisable to hire a professional insulation contractor. These experts have the knowledge and experience to assess the performance and condition of the insulation. They can conduct various tests and inspections to identify any issues or areas in need of improvement. Additionally, insulation contractors can provide advice on maintenance, repairs, or recommending alternative insulation options if necessary.

Assessing Performance and Condition

During a professional inspection, the performance and condition of the fiberglass insulation will be evaluated. This includes assessing the R-value, installation quality, presence of gaps or voids, and any signs of moisture damage or mold growth. The insulation contractor may use specialized tools or techniques to identify issues that may not be visible to the naked eye. Based on their findings, they can provide a comprehensive assessment of the insulation’s performance and condition.

Repair or Replacement Recommendations

Following the inspection, the insulation contractor will provide recommendations for repairs or replacement if necessary. This could involve sealing gaps and air leaks, addressing moisture issues, or improving the overall installation. In some cases, the fiberglass insulation may need to be repaired or replaced to ensure optimal energy efficiency and performance. The contractor can advise on the most suitable course of action based on the extent of the issues and the age of the insulation.

Addressing Fiberglass Insulation Issues

Removing Mold and Mildew

If mold or mildew is present on the fiberglass insulation, it is crucial to address the issue promptly to prevent further damage and potential health concerns. Depending on the extent of the mold growth, professional remediation may be required. This involves safely removing the affected insulation and properly disposing of it. Afterward, the area should be thoroughly cleaned, and any underlying moisture issues should be addressed to prevent future mold growth.

Sealing Air Leaks

To improve the performance of fiberglass insulation, it is important to seal any air leaks in the building envelope. This can be done by applying caulk or weatherstripping around windows and doors, sealing gaps around utility penetrations, and ensuring a tight fit between insulation batts or rolls. By reducing air leakage, the insulation can function more effectively, leading to improved energy efficiency and comfort.

Improving Installation

If the fiberglass insulation was poorly installed or is showing signs of compression or overstuffing, it may be necessary to improve the installation. This can involve removing the existing insulation and reinstalling it correctly, ensuring a proper fit and avoiding gaps or voids. Additionally, it may be necessary to add additional insulation in areas where it is insufficient to achieve the desired R-value. Improving the installation will maximize the insulation’s performance and energy-saving capabilities.

Considering Alternative Insulation

In some cases, it may be beneficial to consider alternative insulation options if fiberglass insulation is not meeting your needs or if there are persistent issues. There are various types of insulation available on the market, including cellulose, spray foam, and mineral wool. Consulting with an insulation professional can help you determine the most suitable insulation material for your specific requirements and budget.

When to Consult an Expert

Persistent Issues

If you have addressed specific issues with your fiberglass insulation but are still experiencing problems, it may be time to consult an expert. A professional insulation contractor can assess the situation and identify any underlying issues that may be contributing to the ongoing problems. They can provide targeted solutions and recommendations based on their expertise and knowledge.

Extensive Damage

If your fiberglass insulation has been extensively damaged, for example, due to water leaks or fire damage, it is crucial to consult an expert. They can assess the extent of the damage and recommend the appropriate course of action, whether it involves repair or replacement of the insulation. Trying to address extensive damage on your own can be challenging and may not result in a satisfactory resolution.

Health Symptoms

If you or your family members are experiencing health symptoms that may be related to fiberglass insulation, it is important to consult a healthcare professional. Symptoms such as respiratory issues, skin irritation, or eye discomfort may indicate exposure to fiberglass fibers. A healthcare professional can assess your symptoms and provide appropriate advice or treatment. Additionally, a professional insulation contractor can assess the insulation for any issues that may be contributing to the health symptoms.

Conclusion

Fiberglass insulation is a versatile and commonly used material that offers several benefits, including energy efficiency, cost-effectiveness, fire resistance, and soundproofing. However, it is important to be aware of the potential issues that can arise with fiberglass insulation, such as moisture absorption, poor installation, air leakage, and health concerns. By understanding the signs of problematic insulation and conducting regular inspections, homeowners can identify and address any issues in a timely manner. Whether through DIY inspections, professional assessments, or expert consultations, maintaining the performance and condition of fiberglass insulation is essential for a comfortable and energy-efficient living environment.