In this article, we will explore the various methods used to test for leaks in HVAC systems. Whether you are a homeowner or a professional HVAC technician, it is crucial to identify and address any leaks as they can significantly impact the efficiency and performance of the system. From visual inspections to advanced techniques like smoke testing and thermal imaging, we will discuss the different approaches you can take to ensure your HVAC system is leak-free. So, let’s dive in and discover how you can effectively test for leaks in your HVAC!

Understanding HVAC Systems

What is HVAC?

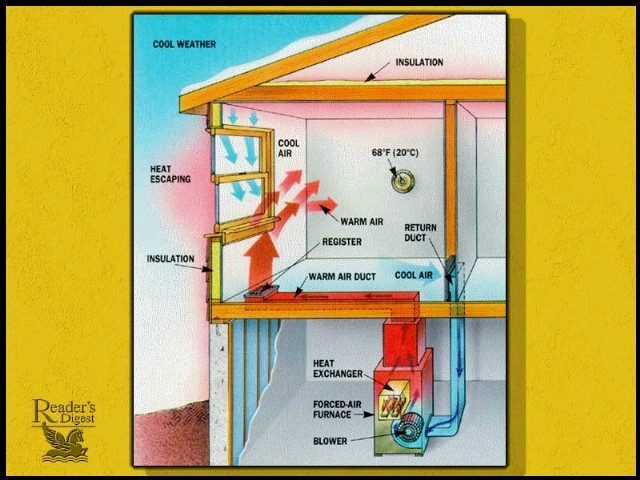

HVAC stands for Heating, Ventilation, and Air Conditioning. It refers to the systems used to control the temperature, humidity, and air quality in indoor spaces. HVAC systems play a crucial role in ensuring comfort and creating a healthy environment in residential, commercial, and industrial buildings.

Components of an HVAC System

An HVAC system consists of several interconnected components that work together to regulate temperature and air quality. The main components include:

- Heating Unit: This component provides heat during colder months and can be powered by electricity, gas, or oil.

- Cooling Unit: The cooling unit, usually an air conditioner or heat pump, removes heat and humidity from the indoor air.

- Air Ducts: These ducts distribute heated or cooled air throughout the building.

- Vents and Grilles: Vents and grilles are the outlets through which air enters or exits the building.

- Thermostat: The thermostat is the control device that allows occupants to adjust the desired temperature.

- Air Filter: The air filter removes pollutants and dust particles from the air before it is circulated.

- Refrigerant Lines: Refrigerant lines carry the refrigerant, a chemical substance that facilitates the cooling process.

- Condensate Drain: The condensate drain removes excess moisture from the cooling process.

Importance of Leak Testing

Leak testing is a critical aspect of HVAC system maintenance and performance optimization. Leaks in HVAC systems can cause a range of issues, including decreased efficiency, increased energy consumption, and potential health hazards. Identifying and addressing leaks in a timely manner is essential to ensure the proper functioning of the system and to prevent further damage.

Types of Leaks in HVAC Systems

Air Leaks

Air leaks occur when there are gaps or openings in the ductwork or around the HVAC system components. These leaks can lead to significant energy losses as conditioned air escapes from the system before reaching its intended destination. Air leaks can also result in uneven heating or cooling, reduced indoor air quality, and increased strain on the HVAC system.

Refrigerant Leaks

Refrigerant leaks can arise in the refrigerant lines or within the HVAC system components. These leaks can cause a decline in cooling performance, leading to longer cooling cycles, insufficient cooling, or complete system failure. Additionally, refrigerant leaks pose environmental concerns as many refrigerants contribute to ozone depletion or have a high global warming potential.

Water Leaks

Water leaks in HVAC systems typically occur in the condensate drain or the drainage system. These leaks can result in water damage, mold growth, and potential health risks. Water leaks may also indicate other underlying issues, such as clogged drain lines or malfunctioning condensate pumps.

Common Signs of HVAC Leaks

Decreased HVAC Performance

One of the most common signs of HVAC leaks is a noticeable decrease in system performance. If your HVAC system takes longer to reach the desired temperature, struggles to maintain a consistent temperature, or has difficulty cooling or heating certain areas of your building, it could be a result of leaks.

Increased Energy Bills

HVAC leaks can significantly impact your energy bills. When leaks are present, your system has to work harder to compensate for the loss of conditioned air or refrigerant. This increased workload translates into higher energy consumption and subsequently, higher energy bills. If you notice a sudden spike in your energy bills without any other explanation, it might be worth investigating for HVAC leaks.

Unpleasant Odors

Leaking refrigerant can produce strong, unpleasant odors. If you notice a strange smell emanating from your HVAC system, particularly a sweet or pungent odor, it could be an indication of a refrigerant leak. These leaks can have adverse effects on indoor air quality and may also pose health risks.

Visible Moisture or Water Damage

Water leaks within the HVAC system can result in visible moisture or water damage around the unit or in the surrounding areas. If you notice water pooling, damp spots, or water stains, it is essential to investigate the issue promptly. Ignoring water leaks can lead to mold growth and further deterioration of the equipment and surrounding structures.

Leak Testing Methods

Visual Inspection

Visual inspection involves a thorough examination of the HVAC system components, ductwork, and connections. This method allows for the identification of visible signs of leaks, such as gaps, cracks, or missing insulation. Visual inspection is a useful first step in the leak testing process and can help diagnose obvious sources of leaks.

Airflow Testing

Airflow testing involves evaluating the movement of air within the HVAC system. This method helps identify areas where air might be escaping or where there may be obstructions affecting the air circulation. Several techniques can be used for airflow testing, including smoke sticks or pencils, thermal anemometer testing, and airflow capture hoods.

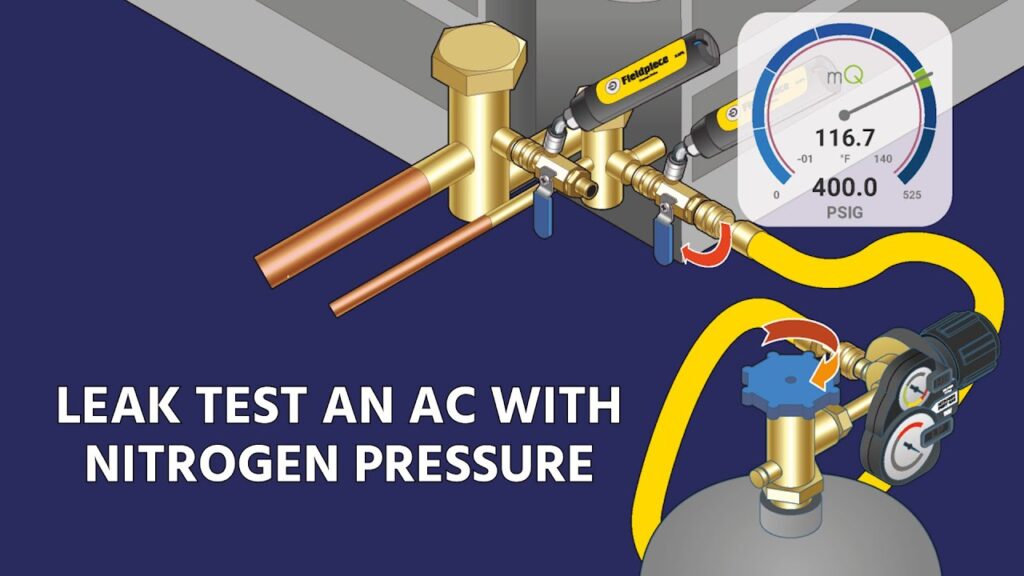

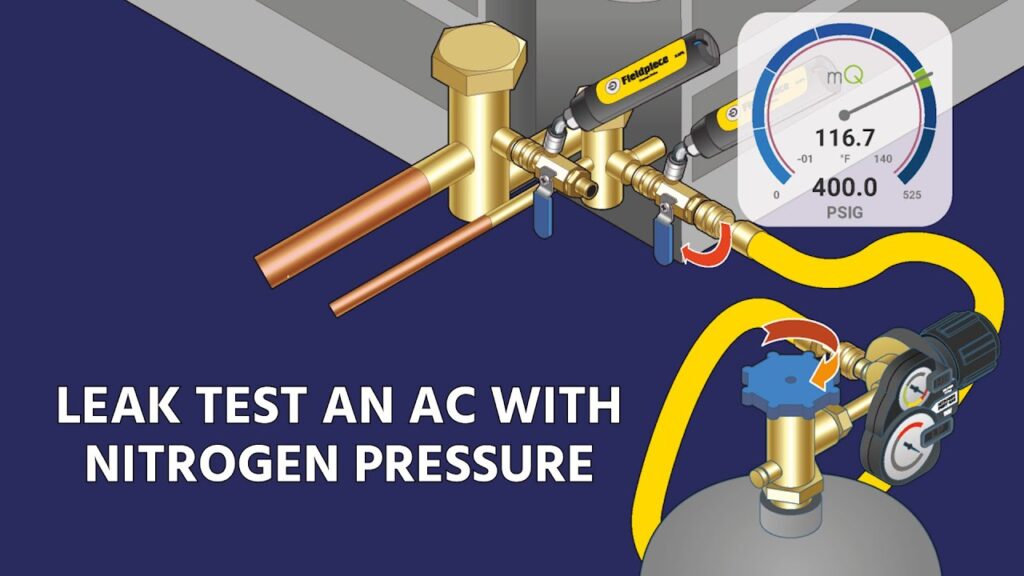

Pressure Testing

Pressure testing involves pressurizing the HVAC system to identify leaks. By creating positive or negative pressure within the system, leaks can be detected through changes in pressure levels. A manometer is commonly used to measure the pressure differentials and pinpoint the location of leaks.

Electronic Leak Detection

Electronic leak detection utilizes specialized equipment to identify leaks in HVAC systems. Ultrasonic leak detectors are used to detect high-frequency sounds emitted by leaking refrigerant or air. Electronic sniffers, on the other hand, can detect trace amounts of refrigerant or other gases. Fluorescent leak detection involves injecting fluorescent dye into the HVAC system and then using UV light to identify leaks.

Dye Testing

Dye testing is another method commonly used to detect refrigerant leaks. It involves injecting a fluorescent dye into the HVAC system, which circulates through the components and lines. If there are any leaks, the dye will escape and become visible under UV light. This method is particularly useful for identifying hard-to-locate leaks.

Visual Inspection of HVAC Systems

General Assessment

During visual inspection, it is important to conduct a general assessment of the HVAC system. This includes inspecting the overall condition of the equipment, checking for signs of wear or damage, and ensuring that all components are properly secured.

Inspecting Ductwork and Joints

Examine the ductwork and joints for any visible signs of leaks, such as loose connections, gaps, or cracks. Insulating materials should also be inspected to ensure they are intact and functioning effectively. Pay close attention to areas where ducts are connected, as these are common areas for leaks to occur.

Checking External Connections

Inspect the external connections of the HVAC system, including the refrigerant lines and electrical connections. Look for signs of oil stains, corroded fittings, or connections that appear loose or damaged. These can indicate refrigerant leaks or potential electrical issues that may affect the performance and safety of the system.

Examining Condensate Lines

Check the condensate lines for any leaks or clogs. These lines are responsible for removing excess moisture from the HVAC system. If there are any visible signs of leakage or water accumulation, it is important to address the issue promptly to prevent water damage and potential mold growth.

Airflow Testing

Using Smoke Sticks or Smoke Pencils

Smoke sticks or smoke pencils can be used to visualize the movement of air within the HVAC system. By introducing smoke into the air ducts or around HVAC components, you can observe the direction and intensity of airflow. Any irregularities or unexpected patterns can indicate the presence of leaks or obstructions.

Thermal Anemometer Testing

Thermal anemometer testing involves using a handheld device to measure the velocity of airflow within the HVAC system. By measuring the airflow at different points, you can identify any significant variations that may indicate leaks or blockages. This method provides quantitative data and can help pinpoint the location and severity of leaks.

Airflow Capture Hoods

Airflow capture hoods are specialized devices designed to measure the volume of airflow coming out of supply registers or returning into the system through return grilles. By comparing the measured airflow with the expected airflow for a given system, you can identify potential leaks or obstructions. Airflow capture hoods are particularly useful for larger HVAC systems.

Pressure Testing

Using Manometer

A manometer is a device used to measure pressure differentials in the HVAC system. Pressure testing involves pressurizing the system with air or nitrogen and using the manometer to measure any changes in pressure. By monitoring pressure levels at different points, you can identify areas where air might be escaping, indicating the presence of leaks.

Creating Positive or Negative Pressure

Positive and negative pressure testing involves modifying the pressure within the HVAC system to detect leaks. Positive pressure testing involves pressurizing the system with air or an inert gas, and checking for any pressure drops over time. Negative pressure testing, on the other hand, involves depressurizing the system and detecting any outside air being drawn in, indicating the location of leaks.

Electronic Leak Detection

Ultrasonic Leak Detectors

Ultrasonic leak detectors are highly sensitive devices that can detect high-frequency sounds produced by escaping gases or liquids. By scanning the HVAC system with an ultrasonic leak detector, you can pinpoint the location of leaks, even in hard-to-reach areas or within complex systems. Ultrasonic leak detectors are particularly effective for refrigerant leak detection.

Electronic Sniffers

Electronic sniffers are portable devices that can detect trace amounts of refrigerant or other gases. They work by sensing the concentration of gases in the surrounding air and alerting the user when a leak is detected. Electronic sniffers can quickly identify the presence of refrigerant leaks and assist in locating the source of the leaks.

Fluorescent Leak Detection

Fluorescent leak detection involves injecting fluorescent dye into the HVAC system. The dye circulates along with the refrigerant or air and will escape through any leaks present. By using a UV light, the dye becomes visible, allowing for easy identification of leaks. Fluorescent leak detection is a reliable method for detecting refrigerant leaks, especially in complex systems.

Dye Testing

Injecting Fluorescent Dye

Dye testing involves injecting a small amount of fluorescent dye into the HVAC system. The dye becomes visible when exposed to UV light, making it easy to identify any leaks or areas of concern. This method is commonly used for refrigerant leak detection but can also be applied to detect water leaks or airflow leaks.

Using UV Light to Detect Leaks

After injecting the fluorescent dye, use a UV light to inspect the HVAC system for any visible signs of leaks. The UV light will cause the dye to fluoresce, making leaks easily detectable. By systematically inspecting each component and joint, you can identify the exact location of leaks and take appropriate measures to repair them.

DIY Leak Testing vs Professional Services

Advantages of Professional Leak Testing

Professional leak testing services offer several advantages over DIY methods. Firstly, professionals have the knowledge and experience to accurately assess and diagnose HVAC system leaks. They have access to specialized equipment, such as ultrasonic leak detectors and electronic sniffers, which are more effective in identifying leaks compared to DIY methods. Additionally, professional leak testing can help detect and address underlying issues that may contribute to leaks or system inefficiencies.

Furthermore, professional leak testing services can provide comprehensive reports and recommendations for repairs or improvements. They can advise on the best course of action to optimize the performance and efficiency of your HVAC system, potentially saving you money on energy bills and preventing future breakdowns.

When DIY Leak Testing is Sufficient

While professional leak testing is beneficial, there are situations where DIY methods may be sufficient. If you have a basic understanding of HVAC systems and the necessary tools, you can perform visual inspections and some airflow testing on your own. DIY methods can be effective in detecting obvious leaks or identifying areas that require further inspection.

However, it is essential to recognize the limitations of DIY testing and know when to seek professional assistance. If you encounter complex issues, suspect refrigerant leaks, or require accurate quantification of airflow or pressure differentials, it is advisable to hire a professional HVAC technician with expertise in leak detection.

In conclusion, leak testing is a crucial step in HVAC system maintenance and optimization. Understanding the different types of leaks and the signs indicating their presence is key to identifying and addressing issues promptly. Whether you choose to perform DIY leak testing or hire a professional, regular leak testing is essential for ensuring the efficiency and reliability of your HVAC system. By implementing appropriate testing methods, you can resolve leaks, improve system performance, and create a comfortable and healthy indoor environment.