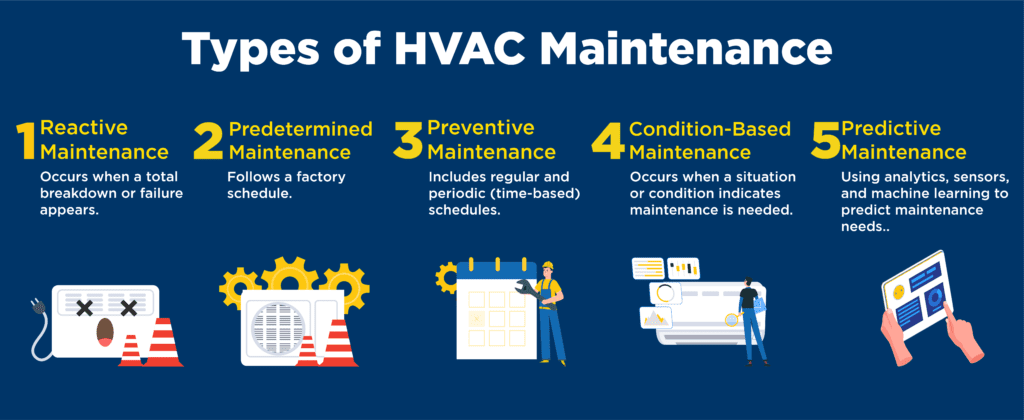

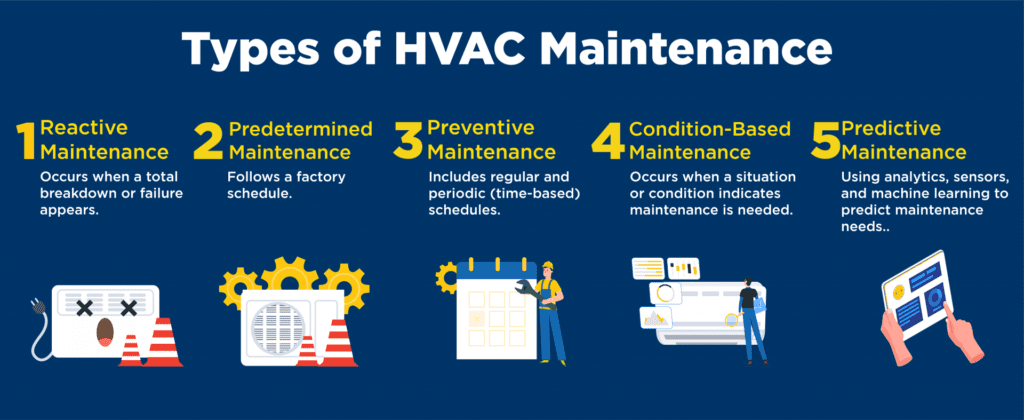

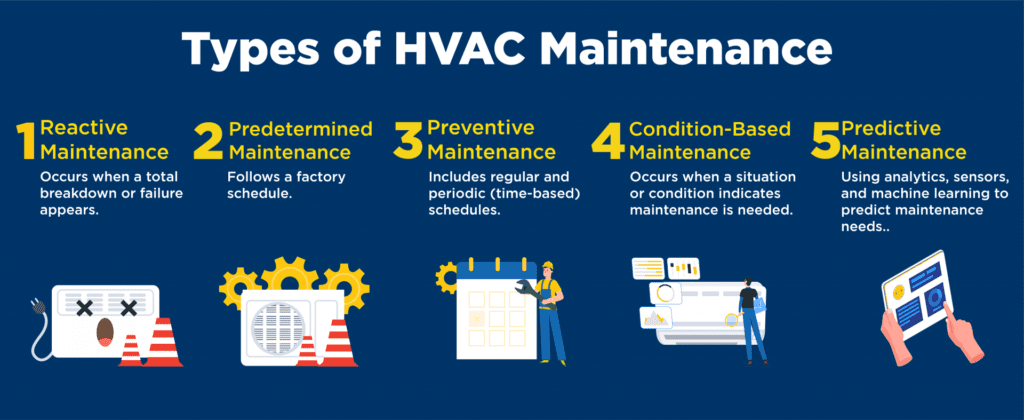

In the realm of HVAC maintenance, there exists a multitude of approaches to effectively keep your heating, ventilation, and air conditioning systems running smoothly. From routine check-ups to preventive measures, this article will explore the various types of HVAC maintenance available to ensure optimal performance and longevity for your beloved systems. Whether you’re a homeowner or a business owner, understanding the different options will empower you to make informed decisions when it comes to keeping your HVAC systems running efficiently.

Preventive Maintenance

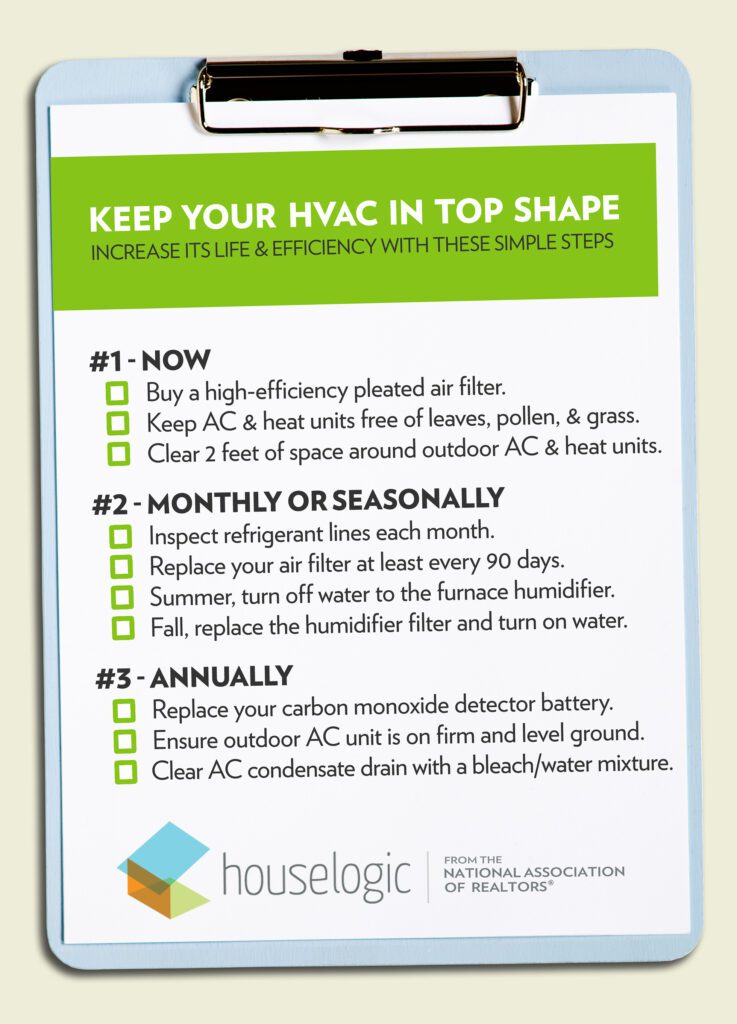

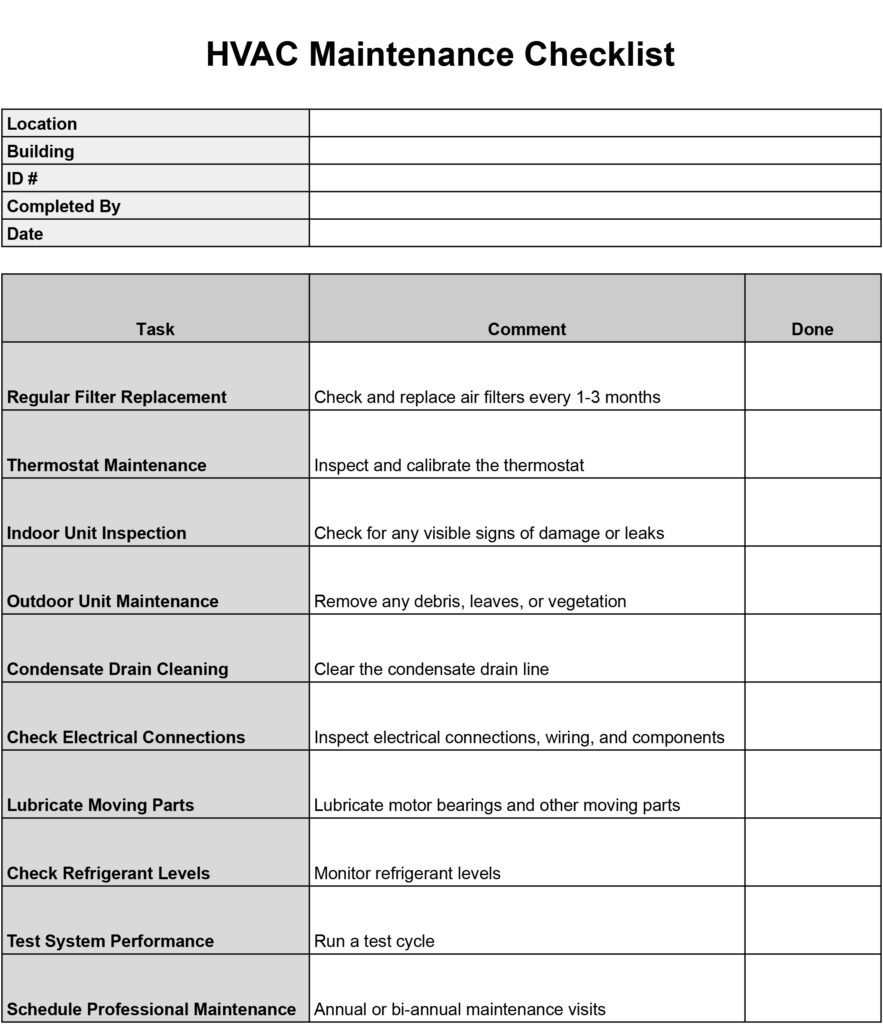

Preventive maintenance is a crucial aspect of keeping your HVAC system running smoothly and efficiently. By regularly cleaning and replacing filters, you can ensure that the air circulating in your home is clean and free of dust, pollen, and other allergens. Clogged filters not only decrease the air quality but also put strain on the system, leading to increased energy consumption and potentially damaging the components.

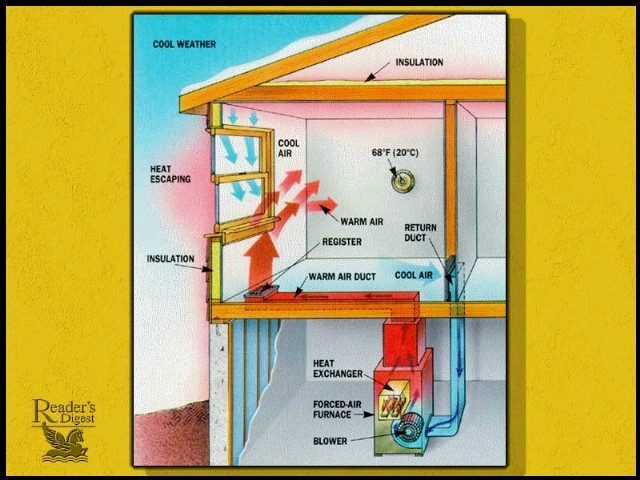

In addition to filters, it is important to clean the coils and ducts of your HVAC system. Over time, dust and dirt can accumulate on the coils, reducing their performance and causing the system to work harder to maintain the desired temperature. By cleaning the coils, you can improve the efficiency of the system and extend its lifespan. Similarly, ducts can become clogged with debris, hindering the flow of air and affecting the overall performance of the system.

Inspecting and lubricating motors and belts is another essential preventive maintenance task. Motors and belts are integral to the functioning of the HVAC system, and regular maintenance ensures they operate smoothly and with minimal friction. Lubricating the motors and inspecting the belts for wear and tear can prevent breakdowns and extend the lifespan of these components.

Checking and repairing electrical connections is an important step in preventing electrical malfunctions and potential hazards. Loose or faulty connections can lead to system failures or even electrical fires. By inspecting and tightening connections, you can ensure the safe and efficient operation of your HVAC system.

Finally, inspecting and adjusting thermostat settings is crucial for maintaining a comfortable temperature in your home while maximizing energy efficiency. Regularly calibrating the thermostat ensures accurate temperature readings and prevents unnecessary strain on the system.

Emergency Maintenance

While preventive maintenance aims to minimize the chances of emergencies, sometimes unexpected issues can arise with your HVAC system. Emergency maintenance involves identifying and fixing leaks, which can cause damage to your property and lead to expensive repairs if left untreated. Promptly addressing leaks can protect your home from water damage and prevent further complications.

Repairing or replacing faulty components is another aspect of emergency maintenance. When a component fails, it can disrupt the entire system and compromise its performance. By quickly identifying the faulty part and taking appropriate action, you can restore functionality and avoid further damage.

In the case of a complete breakdown, emergency maintenance focuses on restoring system functionality as quickly as possible. This may involve troubleshooting the issue, performing repairs, or even replacing the system if necessary. Emergency maintenance ensures that you and your family are not left without heating or cooling for an extended period of time.

Seasonal Maintenance

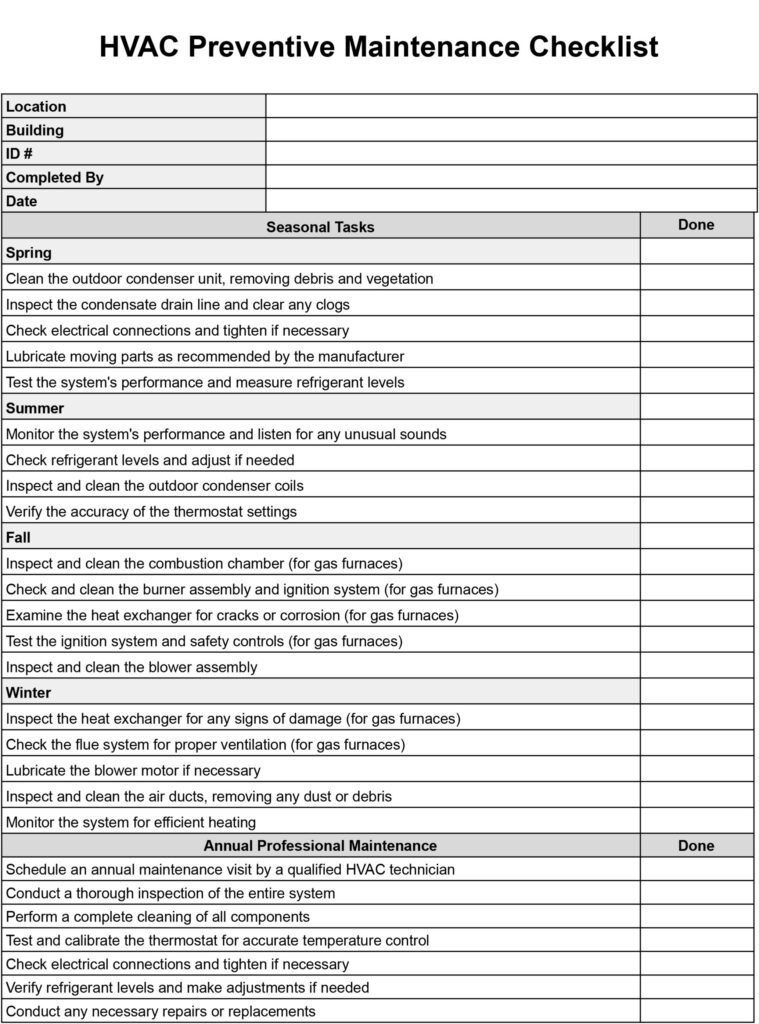

Seasonal maintenance plays a vital role in keeping your HVAC system prepared for the changing weather conditions. It involves specific tasks for both winter and summer seasons.

Before winter arrives, it is important to prepare your HVAC system to efficiently heat your home. This includes inspecting and cleaning the heating components, such as the furnace or heat pump, to ensure they are in optimal condition. Checking and adjusting the thermostat settings for winter temperatures and testing the ignition system are also essential for a smooth transition into the colder months.

Similarly, preparing your HVAC system for the summer involves inspecting and cleaning the cooling components, such as the air conditioner or evaporator coils. Cleaning the condenser unit and ensuring proper airflow are crucial for optimal cooling performance. Additionally, adjusting the thermostat settings to summer temperatures and testing the overall functionality of the system helps to ensure a comfortable indoor environment during the hot summer months.

Checking and adjusting refrigerant levels for optimal performance is another important aspect of seasonal maintenance. Refrigerant is responsible for cooling your home, and insufficient levels can result in reduced cooling efficiency. By regularly monitoring and adjusting the refrigerant levels, you can maximize the performance and longevity of your HVAC system.

Routine Maintenance

Routine maintenance tasks are those that should be performed on a regular basis to keep your HVAC system in top condition. These tasks include inspecting and cleaning condensate drain lines, which remove excess moisture from the system. Over time, these drain lines can become clogged with algae or debris, leading to water backups and potential damage. By cleaning the condensate drain lines, you can prevent water damage and ensure the system operates efficiently.

Checking and adjusting system controls is another routine maintenance task. This involves inspecting the various switches, buttons, and controls of the HVAC system to ensure they are functioning properly. Adjusting the settings as needed ensures optimal performance and efficiency.

Inspecting and cleaning fan blades is also essential for routine maintenance. Over time, fan blades can accumulate dirt and dust, which can affect their balance and performance. Cleaning the blades ensures proper airflow and prevents issues such as noise or reduced cooling/heating efficiency.

Testing and calibrating thermostats is an important routine maintenance task, as inaccurate readings can result in inefficient operation and discomfort. By regularly testing and calibrating thermostats, you can ensure accurate temperature control and energy savings.

Checking and tightening electrical connections is another routine maintenance task that focuses on safety and efficient operation. Loose or faulty electrical connections can result in system malfunctions or even electrical hazards. Regularly inspecting and tightening these connections minimizes the risk of system failures and potential dangers.

Predictive Maintenance

Predictive maintenance goes beyond routine tasks and involves monitoring and analyzing system performance data to detect potential issues before they escalate. By monitoring factors such as energy consumption, temperature differentials, and system pressures, you can identify patterns that may indicate impending failures or necessary adjustments. Analyzing this data allows you to take proactive measures to prevent system breakdowns and optimize performance.

Using technology to predict and prevent potential failures is a key aspect of predictive maintenance. Advanced diagnostics tools and monitoring systems can provide real-time data and alerts, enabling you to detect and address issues promptly. By leveraging these technological advancements, you can effectively maximize system uptime and minimize repair costs.

Implementing strategies to extend the lifespan of equipment is another objective of predictive maintenance. By regularly assessing the condition of components and implementing proactive measures, such as cleaning, lubrication, and adjusting settings, you can significantly prolong the lifespan of your HVAC system. Predictive maintenance aims to optimize the overall performance and longevity of the equipment while minimizing the likelihood of major breakdowns.

Corrective Maintenance

Corrective maintenance is performed when a system malfunction or failure occurs. It involves identifying and diagnosing the specific issue to determine the appropriate course of action. Whether it is a faulty motor, a broken valve, or a malfunctioning control board, corrective maintenance focuses on repairing or replacing the faulty component to restore system functionality.

During corrective maintenance, it is important to thoroughly troubleshoot the system to identify the root cause of the problem. This may involve testing various components, inspecting wiring, or using diagnostic tools to pinpoint the issue accurately. Once the problem is identified, the necessary repairs or replacements can be carried out.

The primary goal of corrective maintenance is to restore the system to its optimal functionality. This may involve replacing the faulty component with a new one or repairing it if possible. Corrective maintenance is typically performed as a reactive response to a system failure, but it is important to remember that proactive maintenance can help minimize the frequency and severity of these failures.

Planned Maintenance

Planned maintenance involves creating a schedule and adhering to regular inspections and servicing of your HVAC system. By setting specific intervals for maintenance tasks, you can ensure that your system receives the necessary attention and preventative measures. Adhering to manufacturer recommendations is essential for planned maintenance, as it helps to preserve warranties and optimize the performance of the equipment.

Creating a maintenance schedule is the first step in planned maintenance. This includes determining the frequency of inspections, cleanings, and replacements based on the specific needs of your HVAC system. The schedule can be tailored to your system’s requirements, taking into account factors such as usage patterns, climate, and manufacturer recommendations.

Performing regular inspections and servicing according to the maintenance schedule is crucial for planned maintenance. This typically involves tasks such as cleaning, lubrication, filter replacements, and system checks. By consistently carrying out these maintenance tasks, you can enhance the efficiency, performance, and lifespan of your HVAC system.

Adhering to manufacturer recommendations is essential for planned maintenance. Manufacturers provide guidelines for maintenance intervals, specific tasks, and recommended replacements. It is important to follow these recommendations to ensure that your HVAC system operates as intended and to avoid voiding any warranties.

Breakdown Maintenance

Breakdown maintenance involves responding to unexpected failures or breakdowns in your HVAC system. When an issue arises, it is important to promptly diagnose and repair the system to minimize downtime and discomfort. Breakdown maintenance focuses on restoring system functionality as quickly as possible.

Diagnosing the cause of the system malfunction is the first step in breakdown maintenance. This may involve inspecting various components, testing electrical connections, or analyzing system performance data. Accurate diagnosis is crucial for determining the appropriate course of action and avoiding unnecessary repairs or replacements.

Once the cause of the breakdown is identified, repairs or replacements can be carried out. This may involve replacing faulty components, repairing electrical connections, or even replacing the entire system if necessary. The primary goal is to restore the functionality of the HVAC system and ensure the comfort of your home.

Breakdown maintenance should be dealt with promptly to prevent further damage and costly repairs. Regular inspections, routine maintenance, and a proactive approach can help minimize the likelihood of breakdowns, but it is important to be prepared for unexpected issues and respond to them efficiently.

Shutdown Maintenance

Shutdown maintenance involves preparing your HVAC system for a temporary shutdown, such as during seasonal closures or renovations. This maintenance is essential to ensure the system remains in good condition during the downtime and is ready for operation when needed again.

Preparing the HVAC system for a temporary shutdown includes several important tasks. Cleaning the system, including the coils, ducts, and filters, ensures that no debris or contaminants are left behind that could affect the system’s performance. Inspecting and cleaning the condensate drain lines prevents any clogs or backups that could cause water damage.

Performing necessary maintenance tasks before shutting down the system is crucial for its longevity. This may include lubricating motors, adjusting belts, and tightening electrical connections. By addressing these maintenance tasks before the shutdown, you can ensure that the system remains in optimal condition throughout the downtime.

Ensuring system readiness after reopening is another aspect of shutdown maintenance. This involves inspecting the system, checking electrical connections, and testing its overall functionality before returning to regular operation. By performing these checks, you can identify any issues or potential problems that may have arisen during the shutdown and address them promptly.

Shutdown maintenance is an important part of the overall maintenance regimen, as it helps to preserve the condition and performance of your HVAC system during periods of inactivity.

Proactive Maintenance

Proactive maintenance focuses on implementing strategies to prevent system failures and maintain optimal conditions. It involves regularly monitoring system performance, taking corrective actions, and leveraging technology to ensure the reliable operation of your HVAC system.

Implementing strategies to prevent system failures is a key aspect of proactive maintenance. This may include tasks such as regular inspections, cleaning, and lubrication, as well as addressing potential issues before they escalate. By staying ahead of potential problems, you can minimize the risk of unexpected breakdowns and reduce repair costs.

Regularly monitoring system performance is crucial for proactive maintenance. This involves tracking factors such as energy consumption, temperature differentials, and system pressures. By analyzing this data, you can identify trends or anomalies that may indicate underlying issues or opportunities for improvement. Monitoring system performance enables you to address any deviations from normal operation promptly and effectively.

Taking corrective actions when necessary is another aspect of proactive maintenance. This involves addressing issues as they arise, rather than waiting for a catastrophic failure. By promptly repairing or replacing faulty components, you can minimize downtime and prevent further damage to the system.

Proactive maintenance also involves leveraging technology to optimize system performance. This includes using advanced diagnostics tools, monitoring systems, and automation to detect potential issues, monitor energy consumption, and optimize settings. By embracing technological advancements, you can enhance the reliability and efficiency of your HVAC system, leading to improved comfort and energy savings.

In conclusion, HVAC maintenance encompasses a wide range of tasks and approaches to ensure the optimal performance and longevity of your heating, ventilation, and air conditioning system. Preventive, emergency, seasonal, routine, predictive, corrective, planned, breakdown, shutdown, and proactive maintenance all play important roles in keeping your HVAC system running smoothly. By adhering to a comprehensive maintenance regimen and addressing issues promptly, you can enjoy a comfortable indoor environment and maximize the efficiency of your HVAC system.