In the world of electrical installations, the question of how much it costs to run conduit per foot is a common concern. Whether you are a contractor, an electrician, or simply someone planning a home project, understanding the expenses involved in running conduit is essential. From material costs to labor fees, this article will shed light on the factors that influence the overall cost of conduits, empowering you to make informed decisions and stay within your budget.

Types of Conduit

When it comes to running conduit, there are several different types to choose from. Each type has its own unique characteristics and is suited for specific applications. Let’s take a closer look at some of the most commonly used types of conduit.

Flexible Conduit

Flexible conduit, also known as “flex,” is a versatile option that is highly recommended for installations that require flexibility. This type of conduit is made of a durable material such as PVC or metal, which allows it to bend and conform to the desired shape. Flexible conduit is ideal for use in tight spaces or areas where frequent movement or vibrations occur.

Rigid Metal Conduit (RMC)

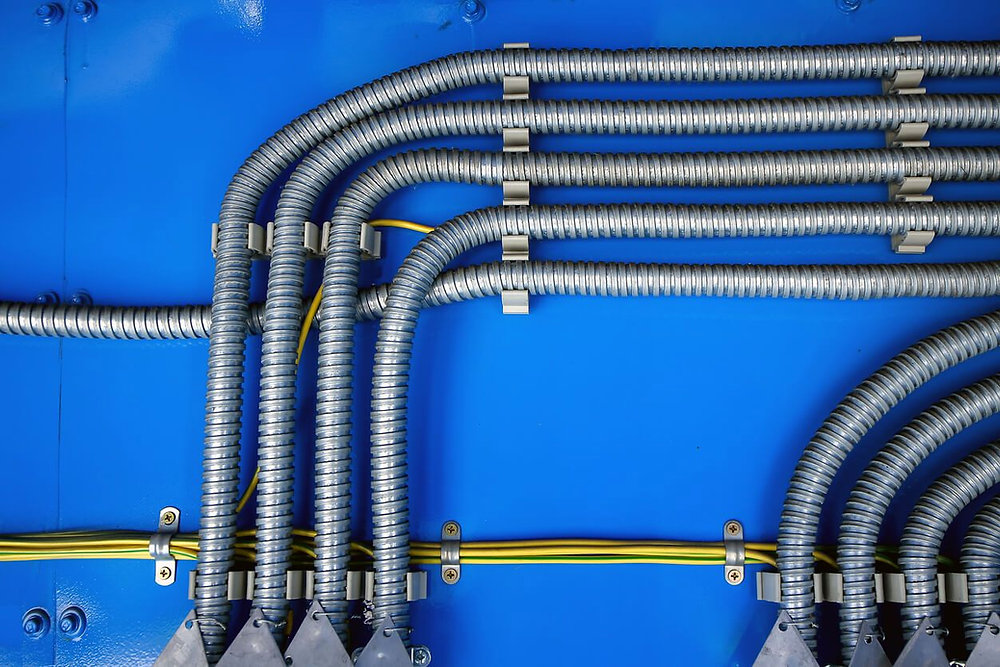

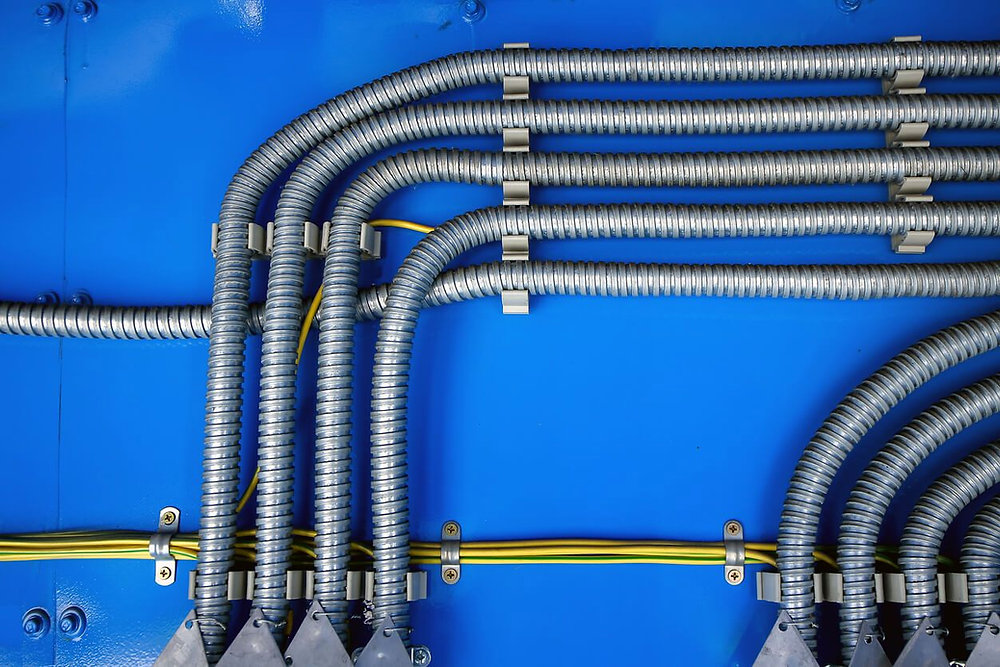

Rigid metal conduit, or RMC, is a strong and durable option that provides maximum protection for electrical wiring. Made of galvanized steel, RMC is the go-to choice for heavy-duty applications where extra protection is required, such as industrial settings or outdoor installations. While RMC may not offer the same flexibility as other types of conduit, it is known for its high durability and longevity.

Electrical Metallic Tubing (EMT)

Electrical metallic tubing, often referred to as EMT, is another popular choice for conduit installations. Made of thin-walled steel, EMT is lightweight and easy to work with. It offers excellent protection for electrical wiring and is commonly used in residential and commercial settings. One of the advantages of EMT is its affordability, making it a cost-effective option for many projects.

Intermediate Metal Conduit (IMC)

Intermediate metal conduit, or IMC, is a type of conduit that combines the strength and durability of RMC with the lightweight characteristics of EMT. Made of galvanized steel, IMC provides protection against physical damage and is suitable for use in a wide range of applications. IMC is commonly used in areas where the conduit needs to be exposed to moisture or corrosive substances.

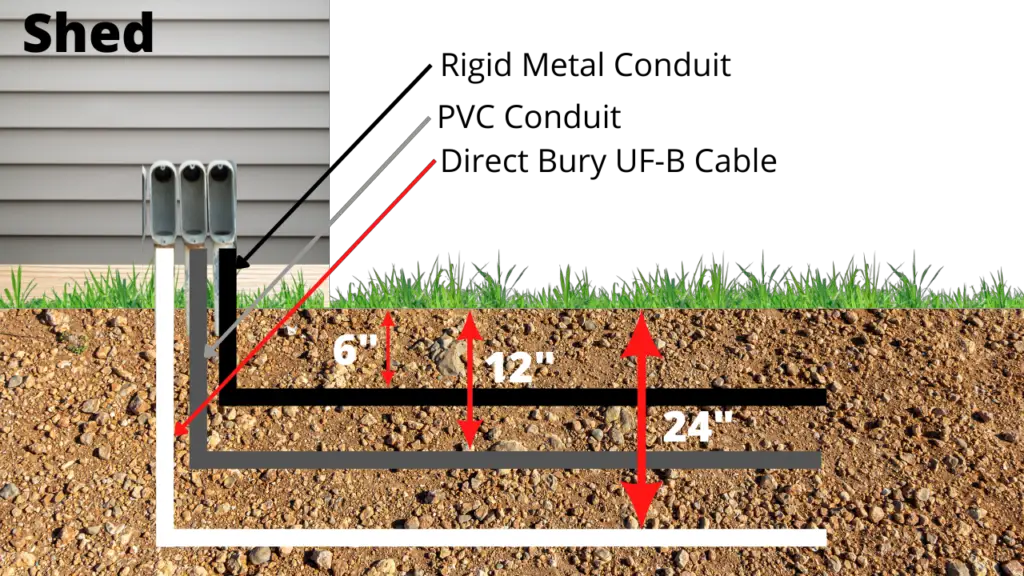

PVC Conduit

PVC conduit is a popular choice for both underground and above-ground installations. Made of polyvinyl chloride, PVC conduit is lightweight, easy to handle, and resistant to moisture and corrosion. It is an affordable option that offers good protection for electrical wiring. PVC conduit is commonly used in residential and commercial construction projects.

Liquidtight Flexible Metal Conduit (LFMC)

Liquidtight flexible metal conduit, also known as LFMC, is a flexible type of conduit that is designed to withstand exposure to liquids and extreme temperatures. It is commonly used in outdoor installations or areas where the conduit may come into contact with water or other liquids. LFMC is made of a metal core that is covered with a liquidtight PVC coating, providing excellent protection and flexibility.

Factors Affecting Cost

Several factors come into play when determining the cost of running conduit per foot. It’s important to consider these factors to ensure that you have a clear understanding of the total cost involved. Let’s take a closer look at some of the key factors that can influence the cost of running conduit.

Type of Conduit

The type of conduit you choose can have a significant impact on the cost. Some types of conduit, such as rigid metal conduit, tend to be more expensive than others. It’s important to weigh the benefits and drawbacks of each type of conduit to determine which one is the most cost-effective for your specific application.

Installation Method

The installation method used can also affect the cost of running conduit per foot. Different installation methods require different levels of skill and labor, which can impact the overall cost. For example, surface-mounted conduit may be less expensive to install compared to concealed conduit, which requires more precise work and may involve additional labor.

Labor Costs

Labor costs play a major role in the overall cost of running conduit. If you decide to tackle the installation yourself, you can save on labor costs. However, keep in mind that installing conduit can be a complex and time-consuming task, especially if you’re not experienced in electrical work. Hiring a professional electrician will ensure that the installation is done correctly but will increase the overall cost.

Location

The location of the conduit installation can also affect the cost per foot. Urban areas tend to have higher labor costs and may require additional permits or inspections, which can increase the overall cost. On the other hand, rural areas may have lower labor costs but may require longer travel distances for the electrician, which could add to the overall cost.

Conduit Size

The size of the conduit needed for your installation can impact the cost per foot. Smaller conduit sizes, such as 1/2-inch or 3/4-inch, are generally less expensive compared to larger sizes like 2-inch or larger. It’s important to determine the appropriate conduit size based on the electrical load and the number of wires that need to be run.

Accessibility

The accessibility of the installation area can also affect the cost of running conduit per foot. If the area is easily accessible and doesn’t require additional labor or specialized equipment, the cost may be lower. However, if the area is difficult to access and requires extra effort or equipment, the cost may be higher.

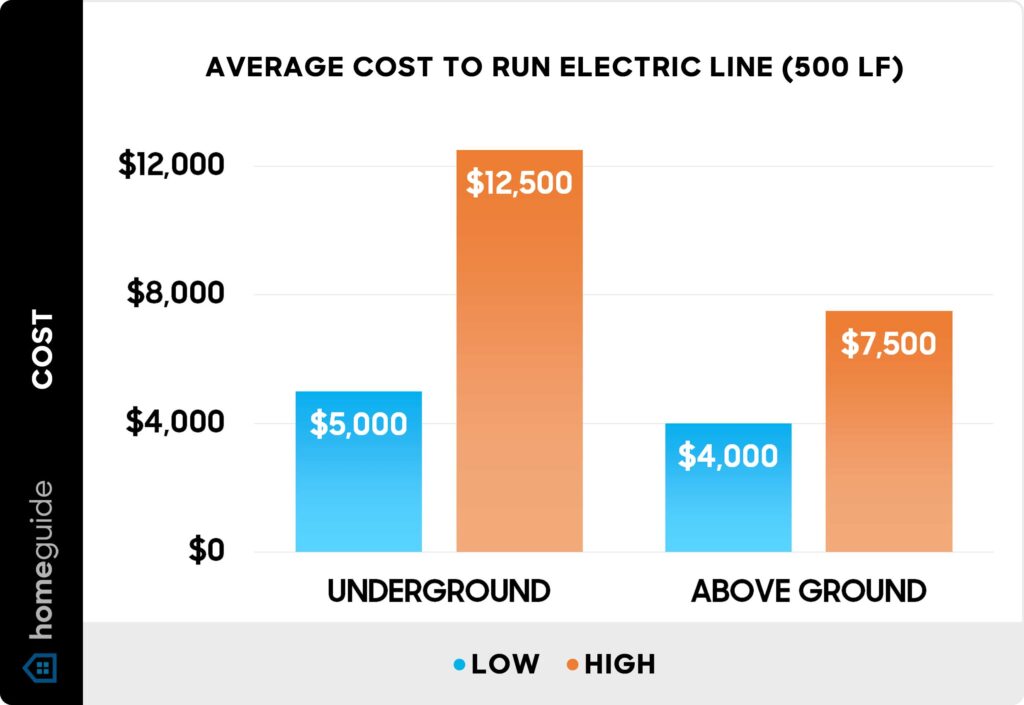

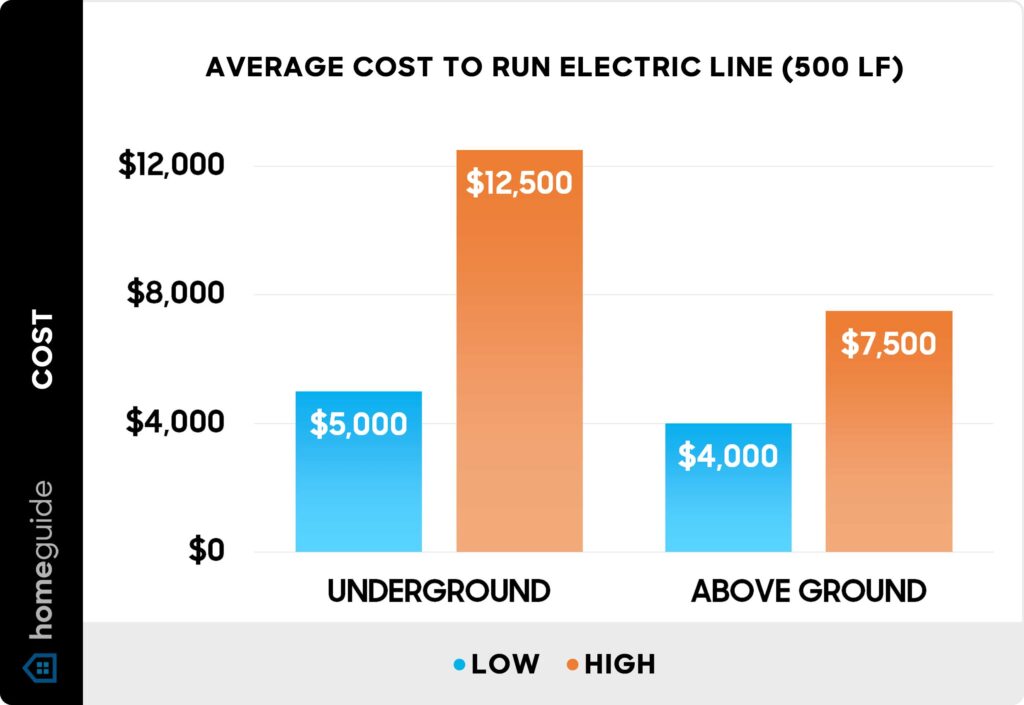

Average Costs per Foot

Now that we’ve discussed the factors that can affect the cost of running conduit, let’s take a look at the average costs per foot for different types of conduit. Please note that these prices are approximate and can vary based on various factors such as location, labor costs, and market conditions.

- Flexible Conduit: $1 – $6 per foot

- Rigid Metal Conduit (RMC): $2 – $10 per foot

- Electrical Metallic Tubing (EMT): $0.40 – $2.50 per foot

- Intermediate Metal Conduit (IMC): $1 – $8 per foot

- PVC Conduit: $0.40 – $1.50 per foot

- Liquidtight Flexible Metal Conduit (LFMC): $1.50 – $8 per foot

Keep in mind that these prices are for the conduit only and do not include the cost of fittings, connectors, or accessories that may be required for the installation.

Installation Methods

There are several different installation methods for running conduit. The method you choose will depend on factors such as aesthetics, accessibility, and code requirements. Let’s take a closer look at some common installation methods.

Surface-Mounted Conduit

Surface-mounted conduit is installed on the surface of walls or ceilings, making it easily accessible. This method is often used when the conduit needs to be visible or when retrofitting in existing buildings. It is a cost-effective option that requires minimal invasive work.

Concealed Conduit

Concealed conduit is hidden behind walls, ceilings, or floors, providing a clean and unobtrusive appearance. This method is commonly used in new construction or renovation projects where aesthetics are a priority. Concealed conduit requires careful planning and coordination with other trades, and may involve additional labor and skill.

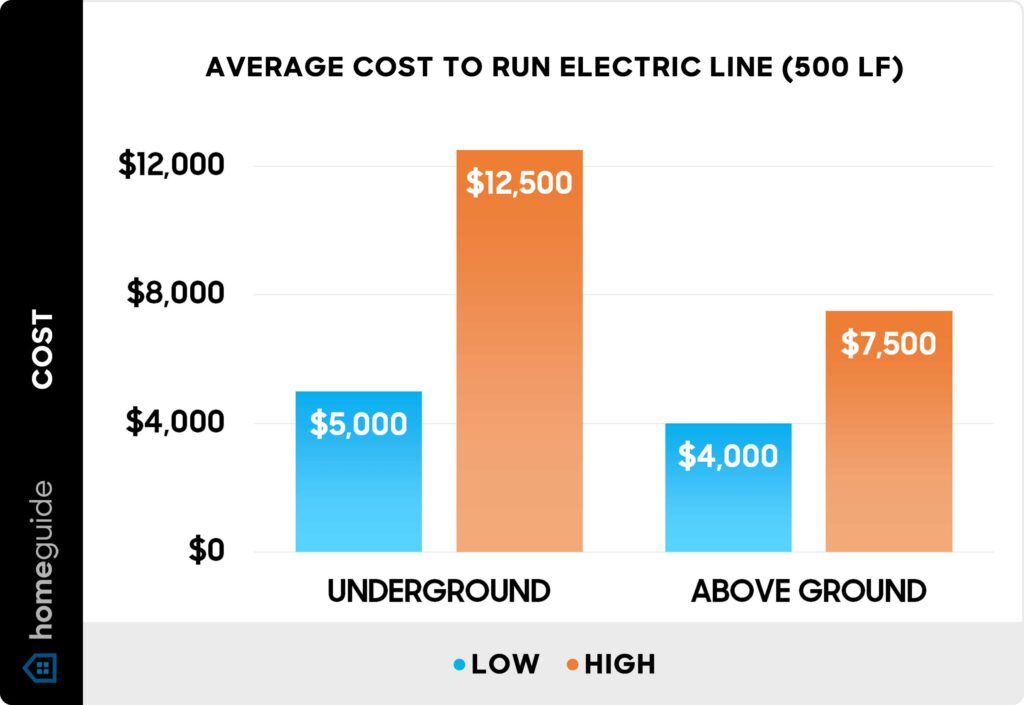

Underground Conduit

Underground conduit is installed below the ground, typically in trenches or conduits. This method is commonly used for outdoor installations or when electrical lines need to be run between buildings. Underground conduit requires careful planning and coordination with other utilities, and may involve additional materials and labor for excavation.

Conduit in Slab

Conduit in slab installations involve embedding the conduit within a concrete slab or floor. This method is typically used in commercial or industrial settings where the conduit needs to be protected and concealed. Conduit in slab installations require precise planning and coordination with other trades, and may involve additional labor for concrete work.

Labor Costs

Labor costs are a significant factor when determining the overall cost of running conduit. The amount of labor required will depend on factors such as the complexity of the installation, the number of bends or turns, and the accessibility of the installation area. Let’s take a closer look at two common labor options.

DIY Installation

If you have experience and knowledge in electrical work, you may choose to tackle the installation yourself. While this can save on labor costs, it’s important to note that working with electrical systems requires expertise and adherence to safety codes. Make sure you have the necessary skills and knowledge before attempting a DIY installation.

Hiring a Professional Electrician

Hiring a professional electrician ensures that the installation is done correctly and meets all safety codes and regulations. Electricians have the knowledge, experience, and tools to handle conduit installations efficiently and effectively. While hiring a professional electrician will increase the overall cost, it provides peace of mind and ensures a high-quality installation.

Location

The location of the conduit installation can affect the overall cost due to variations in labor costs and local regulations. Let’s take a closer look at how location can impact the cost.

Urban Areas

In urban areas, labor costs tend to be higher compared to rural areas. Electricians in urban areas have higher overhead costs and may need to obtain additional permits or undergo inspections, which can add to the overall cost. Additionally, working in densely populated areas may require more precise work and coordination with other trades, resulting in increased labor costs.

Rural Areas

Labor costs in rural areas tend to be lower compared to urban areas. Electricians in rural areas often have lower overhead costs and may have lower travel expenses. However, working in remote or less densely populated areas may require longer travel distances for electricians, which could add to the overall cost.

Conduit Size

The size of the conduit needed for your installation will impact the cost per foot. Conduit size is determined based on the electrical load and the number of wires that need to be run. Let’s take a look at some common conduit sizes and their applications.

1/2-inch

1/2-inch conduit is commonly used for residential applications, such as running electrical wiring for lighting or outlets in homes. It is an affordable and versatile option for low-voltage installations.

3/4-inch

3/4-inch conduit is used for a wide range of applications, both residential and commercial. It is suitable for running electrical wiring for various systems, including lighting, outlets, and HVAC equipment.

1-inch

1-inch conduit is commonly used for commercial and industrial applications. It is suitable for running larger electrical loads and is often used for motors, machinery, or heavy-duty equipment.

1 1/4-inch

1 1/4-inch conduit is used for applications that require even larger electrical loads, such as industrial machinery or high-powered equipment.

1 1/2-inch

1 1/2-inch conduit is commonly used for industrial installations or applications that require a high number of wires, such as data centers or manufacturing facilities.

2-inch

2-inch conduit is used for heavy-duty applications that require large electrical loads, such as industrial or commercial buildings with high-powered equipment.

Larger Sizes

For installations that require even larger conduit sizes, such as for power transmission or distribution systems, larger conduit sizes are available. These may include 3-inch, 4-inch, or even larger sizes.

Accessibility

The accessibility of the installation area can impact the cost of running conduit per foot. Let’s take a closer look at how accessibility can affect the overall cost.

Easy Access

If the installation area is easily accessible, such as open walls or ceilings, the cost of running conduit per foot may be relatively lower. Easy access allows for efficient installation and minimizes the need for additional labor or specialized equipment.

Difficult Access

If the installation area is difficult to access or requires additional effort, such as tight spaces, confined areas, or areas with obstructions, the cost of running conduit per foot may be higher. Difficult access may require extra labor or specialized equipment, resulting in increased overall costs.

Additional Costs

In addition to the cost of conduit per foot, there may be several additional costs to consider when running conduit. Let’s take a look at some common additional costs.

Permits and Inspections

Depending on your location and the type of installation, you may be required to obtain permits and undergo inspections. These permit fees and inspection costs can add to the overall cost of running conduit. It’s important to check with your local authorities to determine the specific requirements and associated fees.

Material Costs

In addition to conduit, you may need to purchase other materials such as fittings, connectors, junction boxes, or conduit straps. These materials can vary in cost and will depend on the specific requirements of your installation. It’s important to factor in these material costs when estimating the overall cost.

Fittings and Connectors

Fittings and connectors are essential components of conduit installations. They allow for secure connections, bends, or branches in the conduit system. The cost of fittings and connectors can vary based on the type and size of conduit used. It’s important to choose high-quality fittings and connectors to ensure a reliable and safe installation.

Conclusion

Running conduit is an important part of electrical installations, providing protection and organization for electrical wires. The cost of running conduit per foot can vary based on several factors such as the type of conduit, installation method, labor costs, location, conduit size, accessibility, and additional costs.

It’s important to carefully consider these factors and weigh the benefits and drawbacks of each option to determine the most cost-effective solution for your specific application. Whether you choose to install the conduit yourself or hire a professional electrician, proper planning and adherence to safety codes and regulations are crucial.

By understanding the various types of conduit, factors affecting cost, average costs per foot, installation methods, labor costs, location considerations, conduit sizes, accessibility, and additional costs, you can make informed decisions and ensure a successful conduit installation that meets your needs and budget.