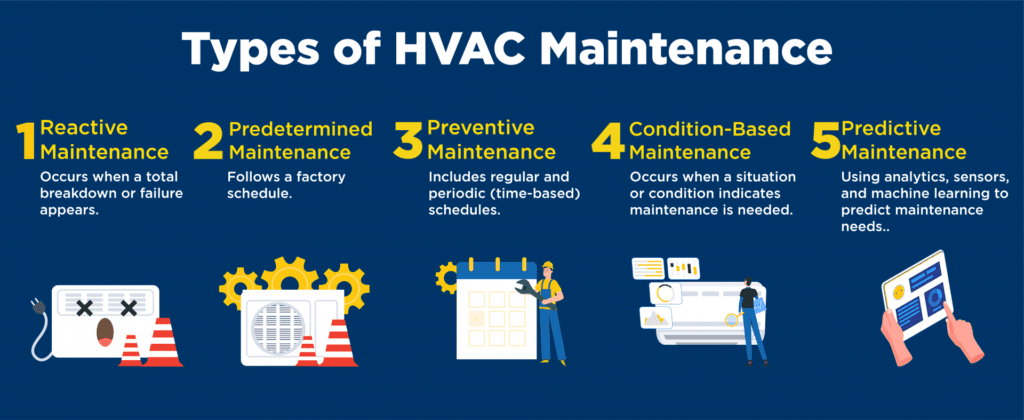

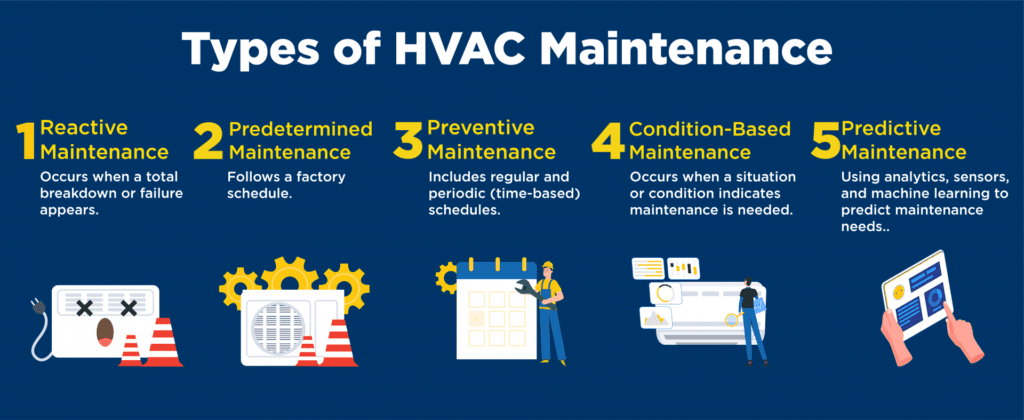

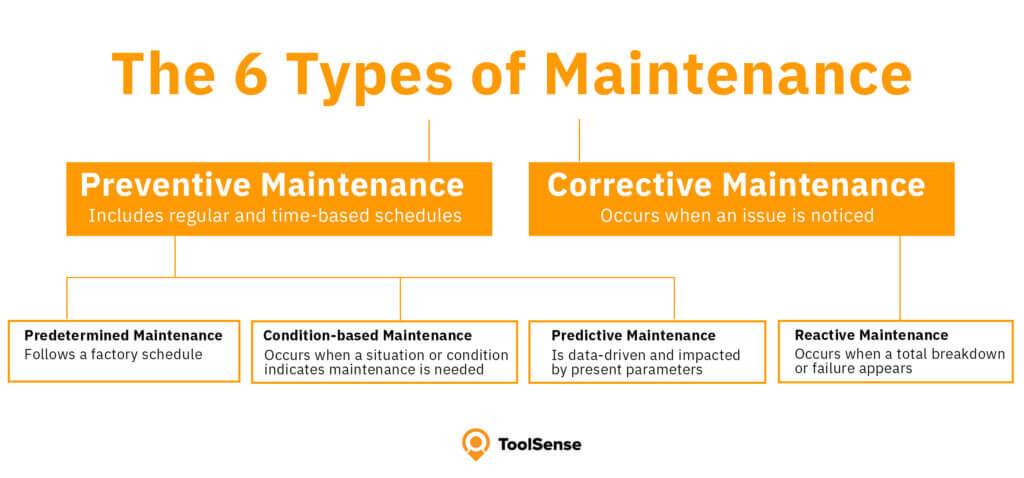

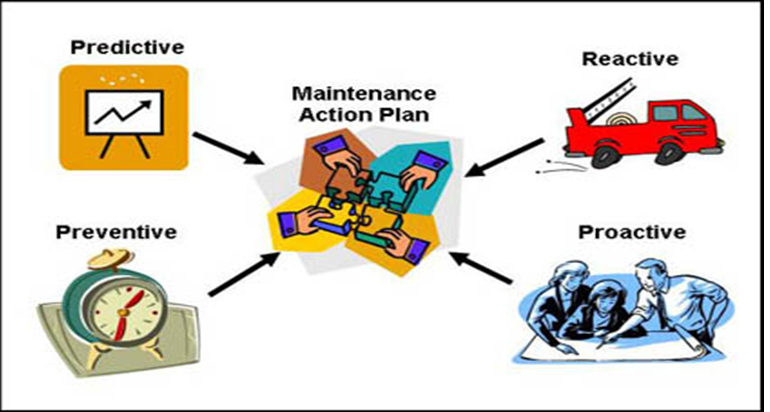

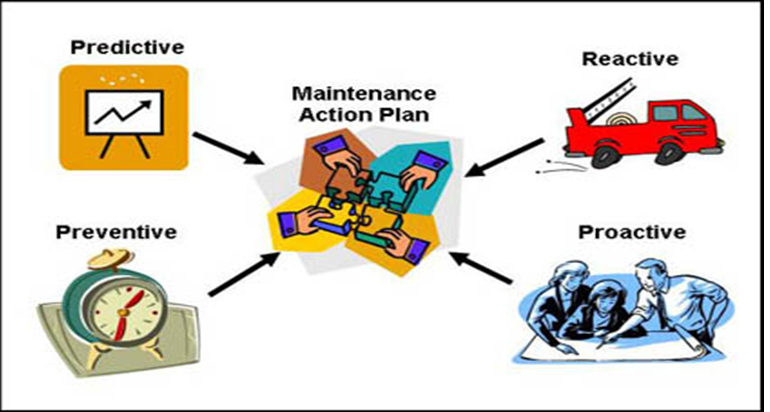

In this article, you will discover the four different types of maintenance HVAC. Whether you are a homeowner or a business owner, understanding these maintenance types can help you ensure the optimal performance and longevity of your HVAC system. From preventive maintenance to predictive maintenance, each type plays a crucial role in keeping your HVAC system running smoothly. So, let’s dive right in and explore these four maintenance types that will ensure your HVAC system stays in top-notch condition.

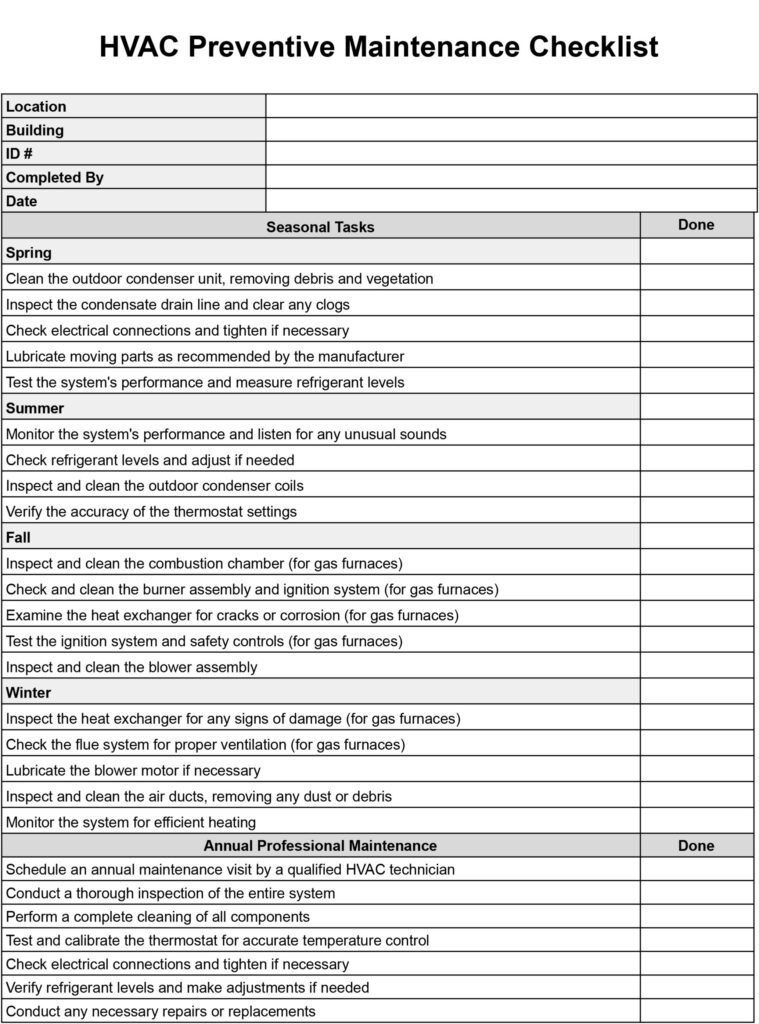

Preventive Maintenance

Definition

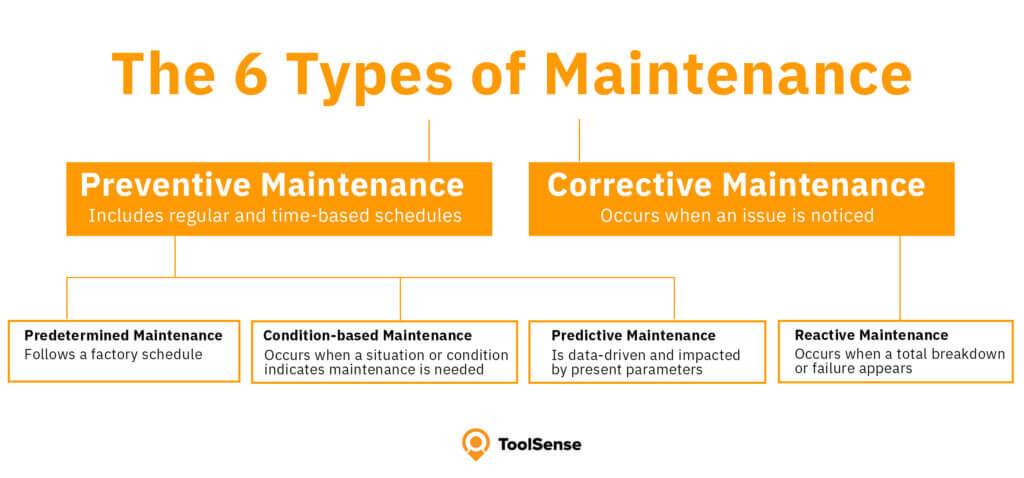

Preventive Maintenance is a proactive approach to HVAC maintenance that focuses on regular inspections, cleaning, and adjustments to prevent potential issues before they arise. It involves scheduled maintenance tasks to ensure that the HVAC system is operating at its optimal performance and to extend its lifespan.

Purpose

The purpose of preventive maintenance is to minimize the risk of unexpected breakdowns and costly repairs by identifying and addressing potential problems early on. By performing regular inspections and maintenance tasks, you can identify and fix issues such as worn-out belts, loose connections, or clogged air filters before they escalate into major problems.

Tasks involved

Preventive maintenance tasks may include cleaning or replacing air filters, lubricating moving parts, inspecting electrical components, testing thermostat accuracy, checking and adjusting refrigerant levels, and cleaning condenser coils. These tasks ensure that the HVAC system is running efficiently and effectively, reducing the risk of breakdowns and prolonging the lifespan of the equipment.

Corrective Maintenance

Definition

Corrective Maintenance is a reactive approach to HVAC maintenance that involves addressing issues and repairing equipment after a failure or malfunction has occurred. Rather than preventing problems, corrective maintenance focuses on fixing the problem as quickly and efficiently as possible.

Purpose

The purpose of corrective maintenance is to restore the functionality of the HVAC system after a failure or malfunction. It is essential when preventive maintenance measures fail or when unexpected issues arise. Corrective maintenance aims to minimize equipment downtime, restore comfort levels, and keep the HVAC system running smoothly.

Tasks involved

Tasks involved in corrective maintenance may include troubleshooting the problem, identifying the root cause of the issue, repairing or replacing faulty components, and testing and verifying the effectiveness of the repair. These tasks require skilled technicians with the knowledge and expertise to diagnose and rectify the problem efficiently.

Predictive Maintenance

Definition

Predictive Maintenance involves using advanced technologies and data analysis to predict and prevent potential equipment failures. By monitoring and analyzing the performance and condition of the HVAC system, predictive maintenance aims to identify signs of impending failures and address them proactively.

Purpose

The purpose of predictive maintenance is to minimize equipment downtime, reduce repair costs, and maximize the lifespan of the HVAC system. By utilizing real-time data and analytics, potential issues can be identified and addressed before they cause significant disruptions or failures. This proactive approach helps to optimize system performance and improve overall operational efficiency.

Tasks involved

Tasks involved in predictive maintenance include collecting and analyzing data from various sensors and monitoring systems, using advanced analytics to detect patterns or anomalies, and taking proactive measures based on the analysis. This may include adjusting maintenance schedules, replacing or repairing specific components, or implementing predictive maintenance strategies to best address the identified issues.

Condition-based Maintenance

Definition

Condition-based Maintenance is a maintenance approach that relies on the real-time monitoring and assessment of the condition of HVAC equipment. By continuously monitoring key indicators such as vibration, temperature, and pressure, condition-based maintenance can detect deviations from normal operating conditions and take appropriate actions.

Purpose

The purpose of condition-based maintenance is to optimize equipment performance, prevent unexpected failures, and minimize costly repairs. By constantly monitoring the condition of the HVAC system, potential issues can be identified early on, enabling timely maintenance or repairs. This approach helps to improve reliability, reduce downtime, and extend the equipment’s lifespan.

Tasks involved

Tasks involved in condition-based maintenance include installing and maintaining monitoring sensors, collecting and analyzing data, setting threshold parameters for key indicators, and taking immediate action when deviations are detected. The tasks may include adjusting operating parameters, replacing worn-out components, or scheduling additional maintenance activities based on the system’s condition.

Benefits of HVAC Maintenance

Improved system performance

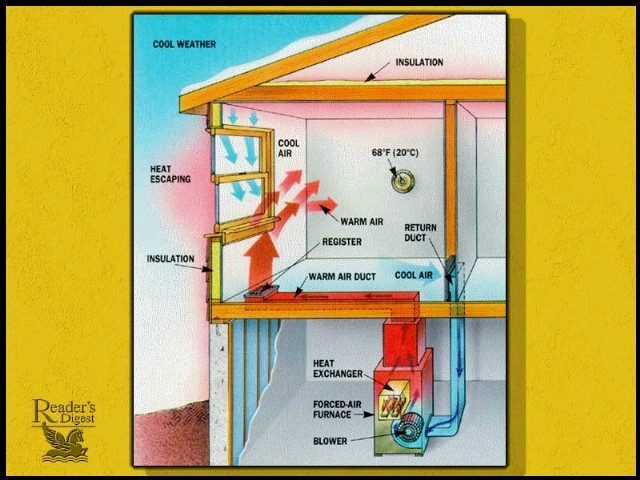

Regular maintenance helps ensure that the HVAC system is operating at its peak performance. By cleaning or replacing air filters and inspecting and adjusting various components, the system can deliver optimal airflow and temperature control, resulting in enhanced comfort and efficiency.

Reduced energy consumption

An efficient HVAC system consumes less energy, resulting in reduced utility bills. Regular maintenance tasks, such as cleaning condenser coils and checking refrigerant levels, can help the system operate more efficiently, minimizing energy waste and maximizing energy savings.

Longer equipment lifespan

Proper maintenance can significantly extend the lifespan of HVAC equipment. By addressing potential issues early on and ensuring that the system is running smoothly, the risk of premature equipment failure is reduced. This, in turn, helps to avoid costly replacements and prolong the lifespan of the equipment.

Cost savings

By proactively addressing potential issues through regular maintenance, HVAC system owners can avoid expensive repairs or major system failures. Preventive maintenance tasks are generally less costly compared to corrective maintenance or emergency repairs, resulting in significant cost savings over time.

Enhanced indoor air quality

Regular maintenance tasks, such as cleaning or replacing air filters, ensure that the HVAC system is effectively filtering out airborne contaminants, improving indoor air quality. This is especially important for individuals with respiratory conditions or allergies, as cleaner air can help alleviate symptoms and promote overall wellbeing.

Key Elements of an HVAC Maintenance Program

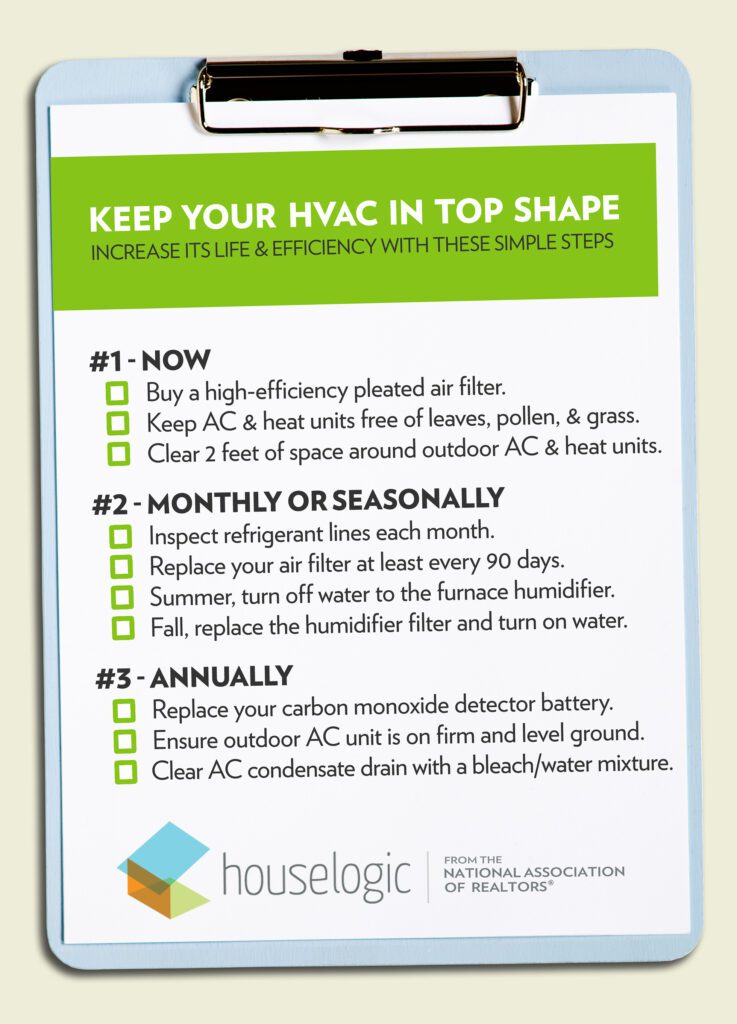

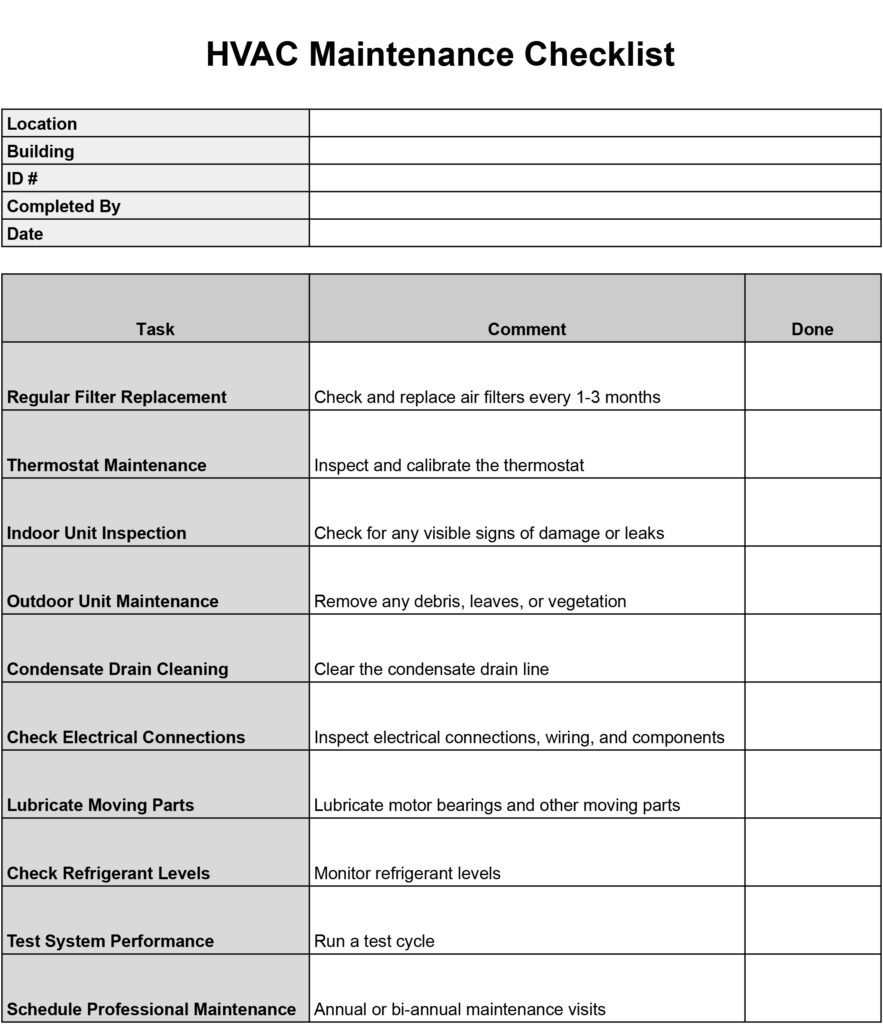

Regular filter replacement

Air filters in the HVAC system should be regularly inspected and replaced to ensure optimal airflow and improve indoor air quality. Clogged or dirty filters can restrict airflow, strain the system, and reduce its efficiency.

Cleaning and lubrication

Cleaning and lubricating moving parts such as motors, fans, and bearings help reduce friction and ensure smooth operation. This can prevent premature wear and tear and extend the lifespan of these components.

Inspection of electrical components

Regular inspection of electrical components, such as wiring, switches, and connections, is essential to identify potential safety hazards or malfunctions. Any signs of wear, overheating, or loose connections should be addressed promptly.

Airflow and refrigerant checks

Monitoring and verifying airflow and refrigerant levels are crucial for ensuring optimum HVAC system performance. Restricted airflow or inadequate refrigerant levels can lead to reduced cooling or heating efficiency and increased energy consumption.

Thermostat calibration

Calibrating thermostats regularly ensures accurate temperature control and optimal performance. Inaccurate thermostat settings can result in temperature inconsistencies and increased energy consumption.

Ductwork inspection

Inspecting the HVAC system’s ductwork for leaks, blockages, or damage is vital to maintain proper airflow and efficiency. Sealing leaks and cleaning ducts can prevent temperature inconsistencies and improve system performance.

Scheduled equipment tune-ups

Regular tune-ups by qualified professionals help identify and address potential issues before they become major problems. This can include inspecting and cleaning components, checking refrigerant levels, testing safety controls, and optimizing system performance.

Documentation and record-keeping

Maintaining a comprehensive record of all maintenance activities, repairs, and system specifications is essential for tracking the system’s performance, identifying trends, and ensuring compliance with warranty requirements.

Factors Influencing Maintenance Frequency

System usage

The frequency of HVAC maintenance depends on how frequently the system is used. A system that operates year-round or in demanding conditions requires more frequent maintenance than one that is used seasonally or in a less demanding environment.

Environmental conditions

The environmental conditions in which the HVAC system operates can affect its maintenance needs. Systems exposed to dusty or polluted environments may require more frequent filter replacements and cleaning to ensure optimal performance.

System age and condition

Older systems generally require more frequent maintenance to ensure their continued performance. The condition of the system, including wear and tear or previous repairs, can also influence maintenance frequency.

Manufacturer’s recommendations

Following the manufacturer’s recommended maintenance schedule is crucial to ensure the system’s longevity and comply with warranty requirements. The manufacturer’s guidelines should be consulted to determine the appropriate maintenance frequency.

Budget constraints

Budget considerations may also influence maintenance frequency. While regular maintenance is essential, the specific frequency of maintenance tasks can be adjusted based on available resources and budget constraints.

Challenges in HVAC Maintenance

Technician availability

Finding skilled and qualified technicians to perform HVAC maintenance can sometimes be a challenge. The demand for HVAC professionals is high, and it can be challenging to find technicians with the necessary expertise and availability to perform maintenance tasks promptly.

Complexity of systems

HVAC systems have become increasingly complex over the years, incorporating advanced technologies and controls. The complexity of these systems can make maintenance tasks more intricate and require specialized knowledge and training.

Budget limitations

Limited budgets can present challenges in maintaining HVAC systems effectively. Adequate maintenance requires regular inspections, necessary repairs, and replacement of components, which may strain budget constraints for some organizations or homeowners.

Obsolescence of equipment

As technology continues to evolve, older HVAC equipment may become obsolete, making it more challenging to find replacement parts or qualified technicians to service the outdated systems. Keeping up with advancements and ensuring compatibility can present maintenance challenges.

Compliance with regulations

The HVAC industry is subject to various regulations and standards related to environmental protection, safety, and energy efficiency. Compliance with these regulations can add complexity to maintenance tasks, requiring additional measures and documentation.

Common HVAC Maintenance Issues

Refrigerant leaks

Refrigerant leaks can lead to reduced cooling or heating efficiency, increased energy consumption, and potential damage to the HVAC system. Regular inspection and monitoring of refrigerant levels can help detect and address leaks promptly.

Dirty filters

Dirty or clogged air filters can restrict airflow, strain the system, and decrease indoor air quality. Regular filter replacement or cleaning helps maintain optimal system performance and improve indoor air quality.

Electrical failures

Electrical failures in the HVAC system can result in system malfunctions, safety hazards, and potential damage to components. Regular inspection of electrical components helps identify and rectify any issues early on.

Defective thermostats

Inaccurate or defective thermostats can lead to temperature inconsistencies, comfort issues, and increased energy consumption. Regular calibration and testing of thermostats ensure accurate temperature control.

Airflow problems

Restricted airflow due to blockages or ductwork issues can reduce system efficiency and lead to temperature inconsistencies. Regular inspection and cleaning of ducts help maintain optimal airflow and system performance.

Condensate drain clogs

Clogs in the condensate drain line can cause water leakage and potential damage to the HVAC system. Regular inspection and cleaning of the condensate drain line help prevent clogs and ensure proper drainage.

Damaged ductwork

Damaged ductwork can lead to air leakage, reduced system efficiency, and inconsistent indoor temperatures. Regular inspection and repairs of ductwork help maintain optimal airflow and system performance.

Conclusion

Regular HVAC maintenance is crucial for ensuring the efficient and reliable operation of heating, ventilation, and air conditioning systems. The various types of maintenance, such as preventive, corrective, predictive, and condition-based, each serve distinct purposes in optimizing system performance and longevity. By implementing a comprehensive maintenance program and addressing common issues and challenges, homeowners and organizations can enjoy improved system performance, reduced energy consumption, prolonged equipment lifespan, cost savings, and enhanced indoor air quality.