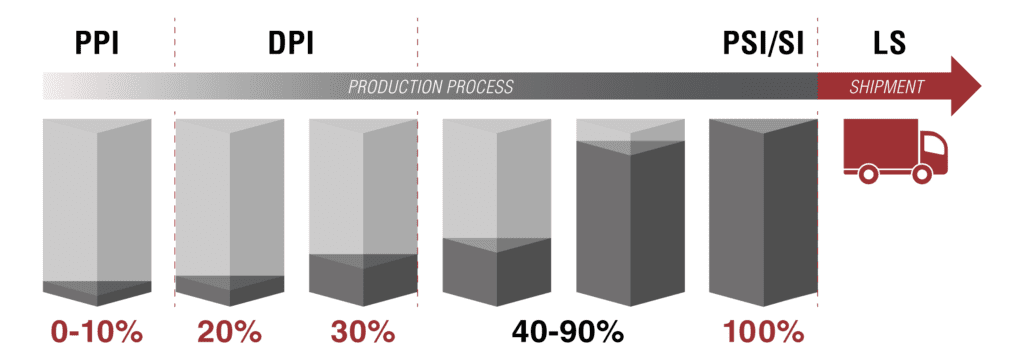

In this article, you will explore the four types of inspections that are commonly conducted. These inspections are essential in various industries to ensure safety, quality, and compliance. By understanding each type of inspection and its purpose, you will gain valuable insights into the importance of thorough examination and assessment.

Visual Inspection

Definition

Visual inspection is a type of inspection that involves evaluating the appearance and condition of an object, area, or equipment. It mainly relies on the sense of sight to identify any visible defects, damages, or discrepancies. This type of inspection does not involve any specialized tools or equipment and can be conducted by anyone with a trained eye.

Purpose

The purpose of visual inspection is to ensure that the inspected object or area meets certain standards and requirements. It helps identify any visible defects or damages that can affect the functionality, safety, or aesthetics of the object or area. Visual inspection is particularly useful for detecting surface-level issues, such as cracks, leaks, unevenness, or general wear and tear.

Procedure

To conduct a visual inspection, start by observing the object or area from different angles and distances. Look for any signs of damage, proper functioning, or overall condition. Take note of any visible defects, such as dents, scratches, corrosion, discoloration, or loose components. It is essential to pay attention to details and thoroughly examine every part of the object or area being inspected.

Examples

Visual inspection can be applied to various scenarios. For instance, in the automotive industry, a visual inspection can be conducted to check the exterior condition of a vehicle, including its body, paint, tires, and lights. In the construction industry, visual inspection can be used to ensure the structural integrity and quality of buildings by examining concrete, steel, and other materials. Additionally, in the food industry, visual inspection plays a vital role in evaluating the appearance and freshness of perishable products, such as fruits, vegetables, or meat.

Physical Inspection

Definition

Physical inspection is a type of inspection that involves a more detailed analysis of an object or area. It goes beyond visual inspection and requires a more hands-on approach. Physical inspection may involve touching, feeling, or using specialized tools and instruments to assess the condition, functionality, or specific characteristics of the object being inspected.

Purpose

The purpose of physical inspection is to obtain a deeper understanding of an object’s or area’s condition, characteristics, or performance. It aims to identify any hidden or non-visible issues that cannot be detected through visual inspection alone. By physically interacting with the object or area, inspectors can gather more accurate and detailed information, leading to better decision-making and problem-solving.

Procedure

To conduct a physical inspection, start by carefully examining the object or area using your senses, including touch, hearing, or smell. Look for any abnormalities, noises, vibrations, or odors that may indicate an issue. Additionally, use specialized tools and instruments, such as gauges, thermometers, or moisture meters, to measure and evaluate specific parameters or characteristics. Take note of any findings and compare them against established standards or guidelines.

Examples

Physical inspection can be applied to various industries and situations. In the manufacturing industry, physical inspection can involve measuring the dimensions, tolerances, or surface roughness of machined parts. In the healthcare sector, physical inspection can include palpating, auscultating, or percussing the body to assess a patient’s health condition. Furthermore, in the electrical industry, physical inspection can be used to test the conductivity, insulation, or resistance of wires, cables, or electrical components.

Safety Inspection

Definition

Safety inspection is a type of inspection that focuses on identifying potential hazards or risks within an object, area, or environment. It aims to ensure compliance with safety standards and regulations, promoting the well-being and protection of individuals. Safety inspections typically involve the evaluation of equipment, procedures, and working conditions to prevent accidents, injuries, or any other safety-related incidents.

Purpose

The purpose of safety inspection is to create a safe and secure environment by proactively identifying and addressing any safety concerns. It helps prevent accidents, injuries, and property damage by ensuring that proper safety measures, equipment, and protocols are in place. Safety inspections are particularly crucial in high-risk industries, such as construction, manufacturing, or healthcare, where the well-being of individuals is of utmost importance.

Procedure

To conduct a safety inspection, start by familiarizing yourself with relevant safety standards, regulations, or guidelines applicable to the object or area being inspected. Evaluate the overall safety culture, including the presence of safety signs, emergency exits, or protective equipment. Identify any potential hazards, such as slippery surfaces, exposed electrical wires, or malfunctioning safety devices. Take note of any non-compliance issues and recommend corrective actions to mitigate risks.

Examples

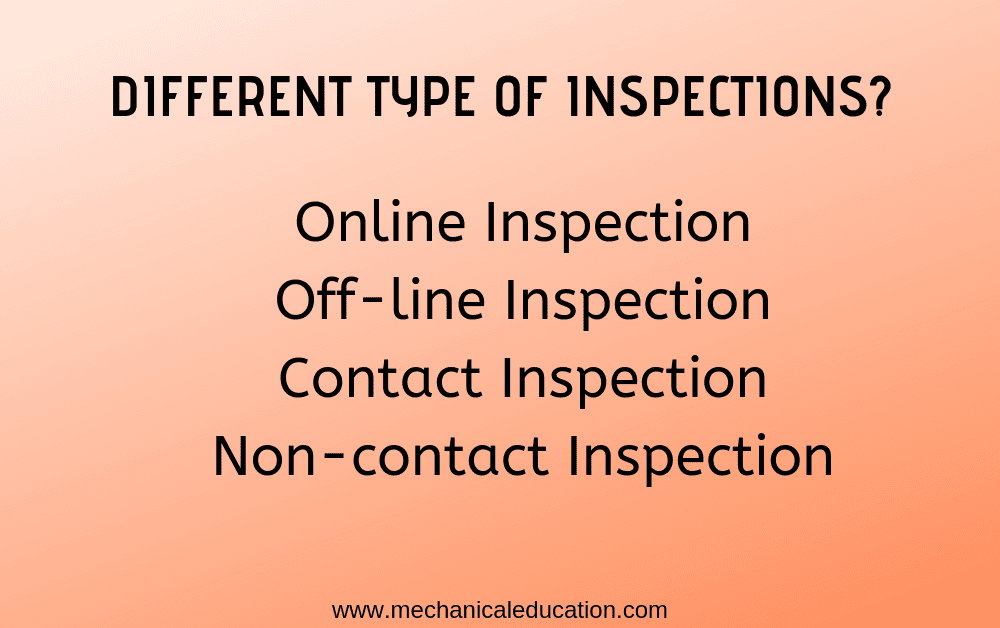

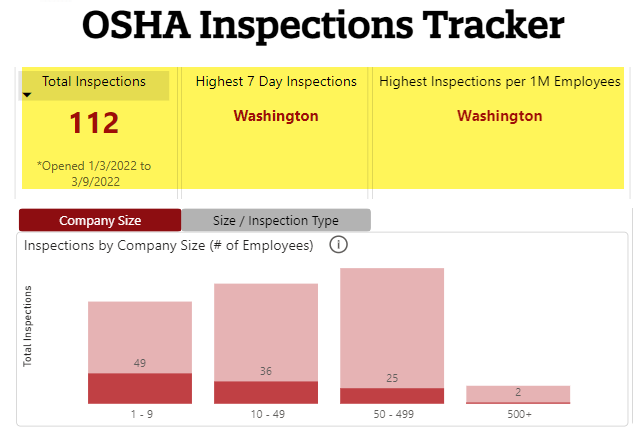

Safety inspections can be applied to various settings. In the workplace, safety inspections can be conducted to ensure compliance with Occupational Safety and Health Administration (OSHA) regulations, including the inspection of fire extinguishers, emergency lighting, or personal protective equipment (PPE). In the transportation sector, safety inspections can involve checking the condition, maintenance, or operational readiness of vehicles, airplanes, or trains. Moreover, safety inspections can be carried out in public spaces, parks, or playgrounds to guarantee the safety of visitors, including checking the stability of playground equipment, absence of sharp edges, or proper lighting.

Quality Inspection

Definition

Quality inspection is a type of inspection that focuses on assessing the overall quality, performance, or conformance to standards of an object, product, or process. It involves evaluating various parameters, characteristics, or specifications to ensure that the inspected item meets predetermined quality criteria. The goal of quality inspection is to identify any deviations or defects that may impact the functionality, reliability, or customer satisfaction.

Purpose

The purpose of quality inspection is to maintain and improve the quality of products, services, or processes. It helps ensure that the inspected items meet or exceed customer expectations. Quality inspections aim to detect any non-conformities, defects, or inconsistencies that may affect the overall performance, functionality, or durability. By identifying and addressing quality issues early on, organizations can enhance customer satisfaction, reduce costs, and establish a positive reputation.

Procedure

To conduct a quality inspection, start by defining the quality criteria, specifications, or requirements for the inspected item. Evaluate various parameters, such as dimensions, weight, color, or functionality, to ensure compliance with the established standards. Utilize specialized tools, such as calipers, scales, or testing equipment, to accurately measure and evaluate the quality characteristics. Document any findings and compare them against the predetermined quality criteria.

Examples

Quality inspections can be applied to a wide range of industries and products. In the manufacturing sector, quality inspections can involve testing the strength, durability, or reliability of materials, components, or assembled products. In the food industry, quality inspections are essential to ensure the freshness, safety, and taste of consumable items, such as fruits, meat, or dairy products. Moreover, in the service industry, quality inspections can be used to evaluate the performance, efficiency, or adherence to standard operating procedures in call centers, hotels, or restaurants.

In conclusion, inspections play a crucial role in various industries and environments. Visual inspection, physical inspection, safety inspection, and quality inspection offer different perspectives and aims, but all contribute to identifying and addressing potential issues, ensuring compliance with standards, and promoting the well-being and satisfaction of individuals. Whether it is evaluating the appearance, condition, safety, or overall quality, inspections are instrumental in maintaining high standards, optimizing performance, and making informed decisions.