So, you want to know what an inspection checklist is? Well, look no further! An inspection checklist is a handy tool used in various industries to ensure that all necessary tasks and requirements are met. It is a comprehensive list of items, criteria, or steps that need to be reviewed, examined, or evaluated during an inspection process. From safety checks at construction sites to quality control assessments in manufacturing plants, an inspection checklist serves as a reliable guide to ensure nothing gets overlooked. Simply put, it’s like a trusty sidekick for inspectors, helping them stay on track and cover all the bases.

1. Definition of an Inspection Checklist

An inspection checklist is a tool used to systematically assess and evaluate the condition, quality, and compliance of various items, processes, or locations. It is a comprehensive list of items, tasks, or requirements that need to be checked during an inspection process. The checklist serves as a guide to ensure that all important aspects are covered and no critical details are overlooked.

1.1 Purpose of an Inspection Checklist

The purpose of an inspection checklist is to facilitate a thorough and consistent evaluation of the subject being inspected. It helps the inspector to stay organized and focused, ensuring that all necessary aspects and components are reviewed. The checklist acts as a reminder of specific items that need to be inspected, serving as a reference point for the inspector throughout the assessment process.

1.2 Components of an Inspection Checklist

An inspection checklist typically consists of a series of items or tasks that need to be evaluated. It may include checkboxes, yes/no questions, or areas for detailed comments. The components can vary depending on the nature of the inspection, but they generally cover aspects such as location details, equipment and tools, operational procedures, safety precautions, and compliance verification.

2. Importance of Using an Inspection Checklist

Using an inspection checklist offers several benefits that contribute to the overall effectiveness and reliability of the inspection process.

2.1 Ensures Consistency

One of the key advantages of using an inspection checklist is that it ensures consistency in the evaluation process. By having a standardized list of items to be assessed, different inspectors can follow the same guidelines and approach. This reduces the possibility of subjective variations in inspections, ensuring that all assessments are conducted in a systematic and fair manner.

2.2 Improves Efficiency

An inspection checklist improves efficiency by providing a clear roadmap for the inspector. With a predefined list of items to review, the inspector can work more efficiently, eliminating the need to constantly refer to external references or recall all necessary aspects to assess. This leads to time savings and enables the inspector to conduct inspections in a more timely and organized manner.

2.3 Enhances Accuracy

Using an inspection checklist enhances the accuracy of evaluations by reducing the likelihood of oversight or missed items. The checklist acts as a reliable reference point, ensuring that no critical aspect is overlooked during the inspection. It helps the inspector to stay on track and systematically evaluate all components, thereby enhancing the overall accuracy and reliability of the inspection process.

2.4 Promotes Safety

Safety is a critical aspect of any inspection process, and an inspection checklist contributes to promoting safety. By including specific safety precautions and guidelines within the checklist, inspectors are reminded to pay attention to potential hazards or risks. This promotes a safe working environment and helps identify and address safety concerns promptly.

2.5 Facilitates Compliance

Compliance with relevant regulations, standards, or guidelines is often a key objective of inspections. An inspection checklist ensures that inspectors cover all necessary compliance verification aspects during the assessment. By including specific compliance requirements within the checklist, it acts as a reminder to assess and document compliance, facilitating adherence to relevant regulations and promoting a culture of compliance.

3. Typical Sections Found in an Inspection Checklist

An inspection checklist typically consists of various sections that cover different aspects of the subject being inspected. While the specific sections may vary depending on the context, there are some common sections often found in inspection checklists.

3.1 General Information

The general information section includes details such as the date and time of the inspection, the name of the inspector, and any other relevant identifying information. This section provides a reference point for future use and helps track the history of inspections.

3.2 Location Details

The location details section captures information about the specific area or site being inspected. It may include details such as the address, building or room number, and any distinct features or characteristics that require attention during the inspection.

3.3 Equipment and Tools

In this section, the checklist outlines the equipment, tools, or machinery that need to be inspected. It may include a list of specific items to be assessed, along with checkboxes or areas for comments regarding their condition, functionality, or compliance with any relevant standards or guidelines.

3.4 Operational Procedures

The operational procedures section focuses on evaluating the processes or procedures followed at the location or site being inspected. It may include a checklist of specific steps or tasks that need to be assessed, ensuring that the operational procedures are being followed correctly and efficiently.

3.5 Safety Precautions

Safety is a critical aspect of inspections, and this section is dedicated to assessing the safety precautions and measures in place. It may include specific safety guidelines or requirements that need to be evaluated, along with areas for comments or observations regarding potential safety hazards or concerns.

3.6 Compliance Verification

The compliance verification section ensures that the subject being inspected adheres to relevant regulations, standards, or guidelines. It may include a checklist of specific compliance requirements or criteria to be evaluated, along with checkboxes or areas for comments regarding the compliance status of each item.

4. Benefits of Using an Inspection Checklist

Using an inspection checklist offers numerous benefits that contribute to the overall effectiveness and efficiency of the inspection process.

4.1 Standardization

An inspection checklist promotes standardization by providing a consistent framework for conducting inspections. By following the same checklist, different inspectors can achieve a consistent level of assessment, reducing variations and ensuring the reliability and fairness of the inspection process.

4.2 Documentation

Using an inspection checklist helps in documenting the inspection process and its outcomes. By systematically recording the findings, observations, and recommendations within the checklist, a comprehensive report can be generated post-inspection. This documentation serves as evidence of compliance or non-compliance, helping organizations address any identified issues and track the progress of improvements.

4.3 Risk Mitigation

An inspection checklist contributes to risk mitigation by helping identify potential hazards, safety concerns, or non-compliant practices. By systematically evaluating critical aspects and including safety precautions within the checklist, organizations can proactively address risks, minimize accidents or incidents, and create a safer working environment.

4.4 Continuous Improvement

Using an inspection checklist enables organizations to identify areas for improvement and promote continuous development. By documenting and analyzing the findings and recommendations generated through inspections, organizations can identify recurring issues, implement corrective actions, and enhance their operational efficiency and overall performance.

5. How to Create an Effective Inspection Checklist

Creating an effective inspection checklist requires careful consideration and attention to detail. The following steps can guide you in developing a checklist that meets your specific requirements.

5.1 Determine the Purpose

Start by clearly defining the purpose of the inspection checklist. Identify the specific objective or goal you hope to achieve through the inspections. This will help you determine the scope, depth, and focus areas of the checklist.

5.2 Identify Inspection Items

Based on the purpose, identify the specific items, areas, or processes that need to be inspected. Break down the subject into distinct components or categories, ensuring that all critical aspects are captured within the checklist.

5.3 Organize Checklist Sections

Organize the checklist into sections that align with the identified items or categories. Consider the logical flow and grouping of related items to ensure ease of use and navigation during inspections.

5.4 Include Clear Instructions

Provide clear instructions within the checklist to guide the inspector on how to conduct the inspection. Include details on the expected evaluation process, references to relevant regulations or guidelines, and any specific considerations or precautions to keep in mind.

5.5 Prioritize Critical Items

Assign priorities to different items or categories based on their criticality. Highlight or indicate items that require immediate attention, ensuring that the inspector focuses on assessing those aspects first. This helps in managing risks and addressing urgent concerns promptly.

5.6 Keep the Checklist Concise

While it is important to capture all necessary details, it is equally crucial to keep the checklist concise and manageable. Avoid overwhelming the inspector with an excessive number of items or irrelevant tasks. Focus on key aspects and keep the checklist user-friendly.

5.7 Validate and Test the Checklist

Before implementing the checklist, validate and test it to ensure its effectiveness and usability. Seek feedback from potential users, conduct trial runs, and make necessary improvements based on the input received. Regularly review and update the checklist to reflect any changes in regulations, standards, or organizational requirements.

6. Examples of Different Inspection Checklists

Inspection checklists can vary widely depending on the nature of the inspection. Here are some examples of different inspection checklists in various contexts:

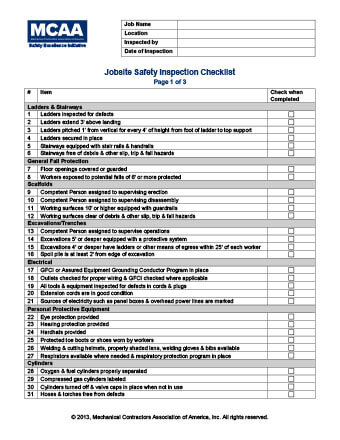

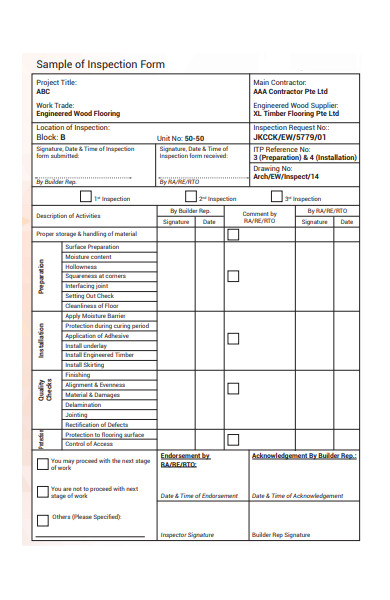

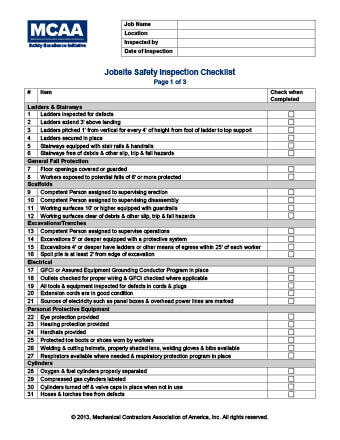

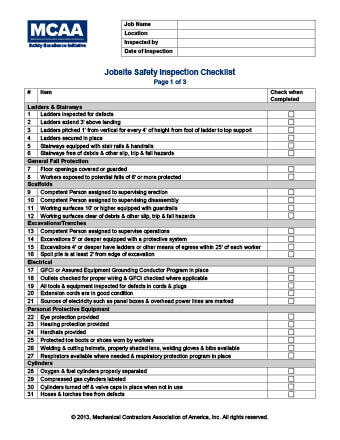

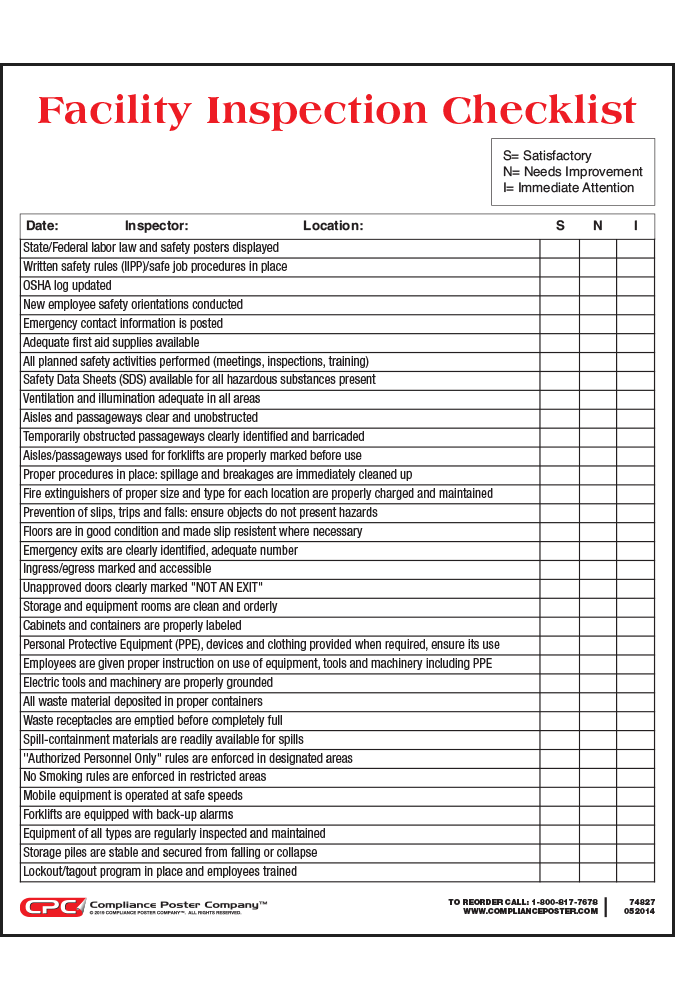

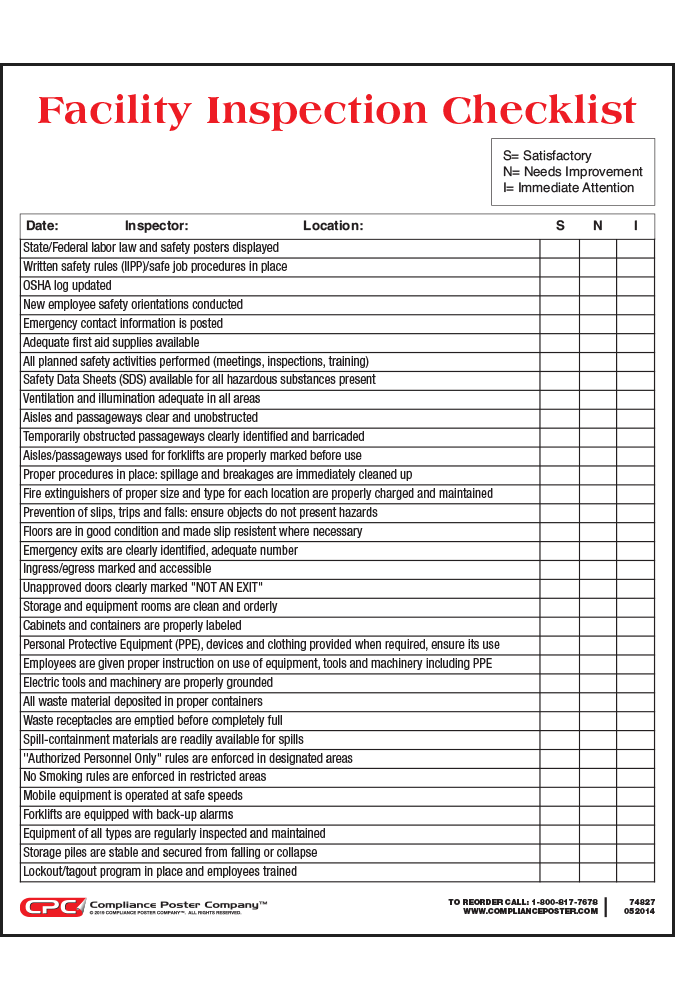

6.1 Workplace Safety Inspection Checklist

A workplace safety inspection checklist focuses on assessing the safety measures and conditions within a workplace. It may include items such as emergency exits, fire safety equipment, proper storage of hazardous materials, and compliance with health and safety regulations.

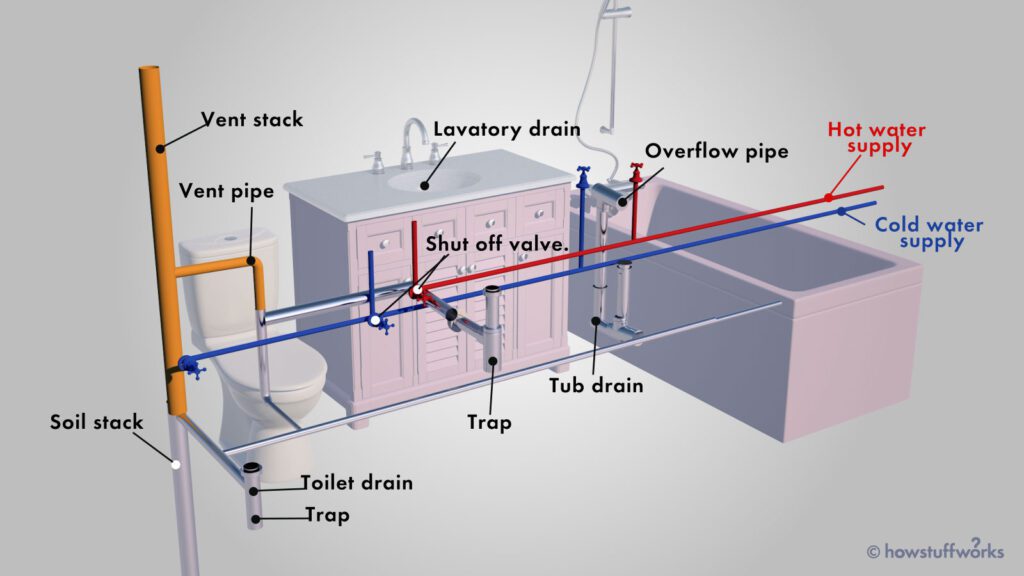

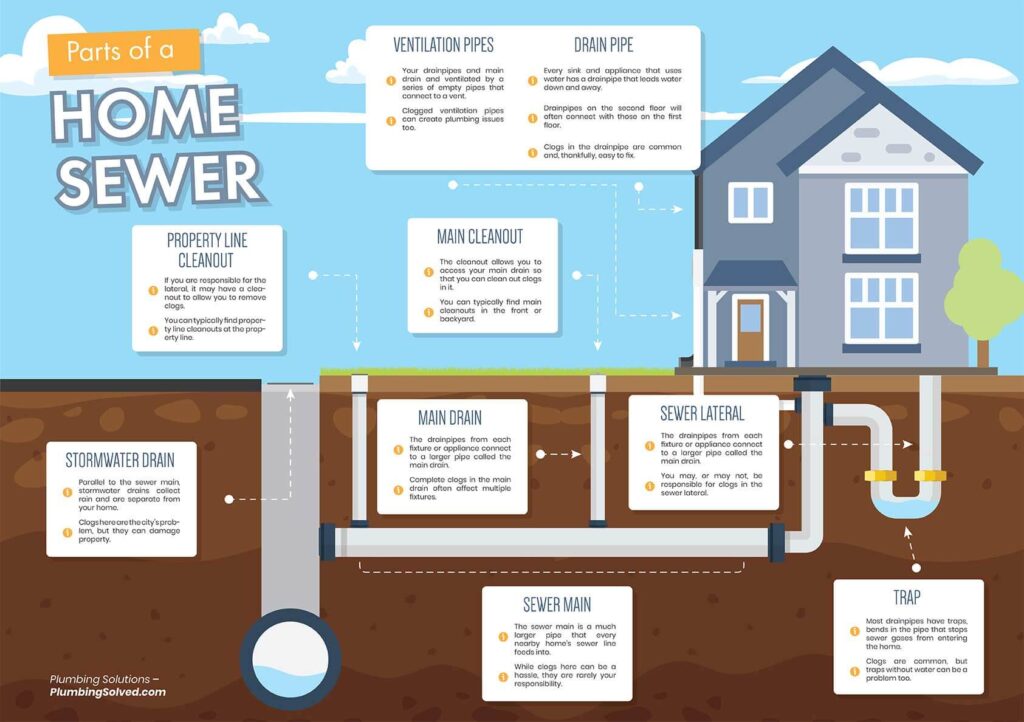

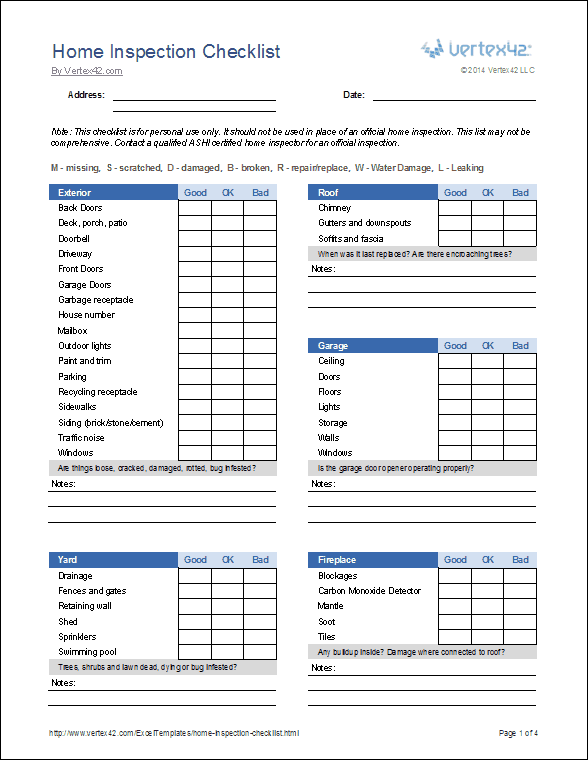

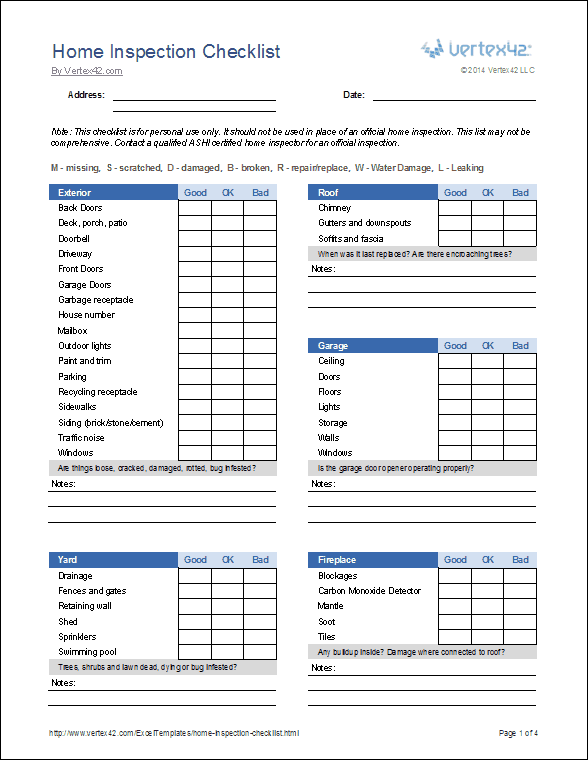

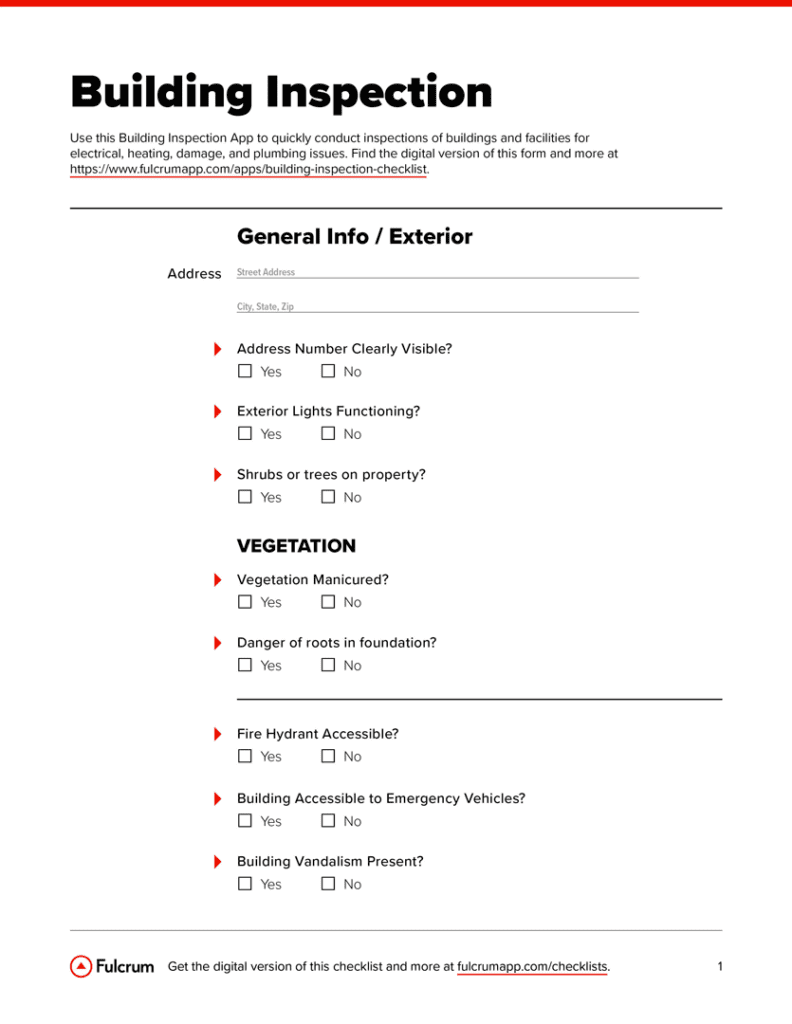

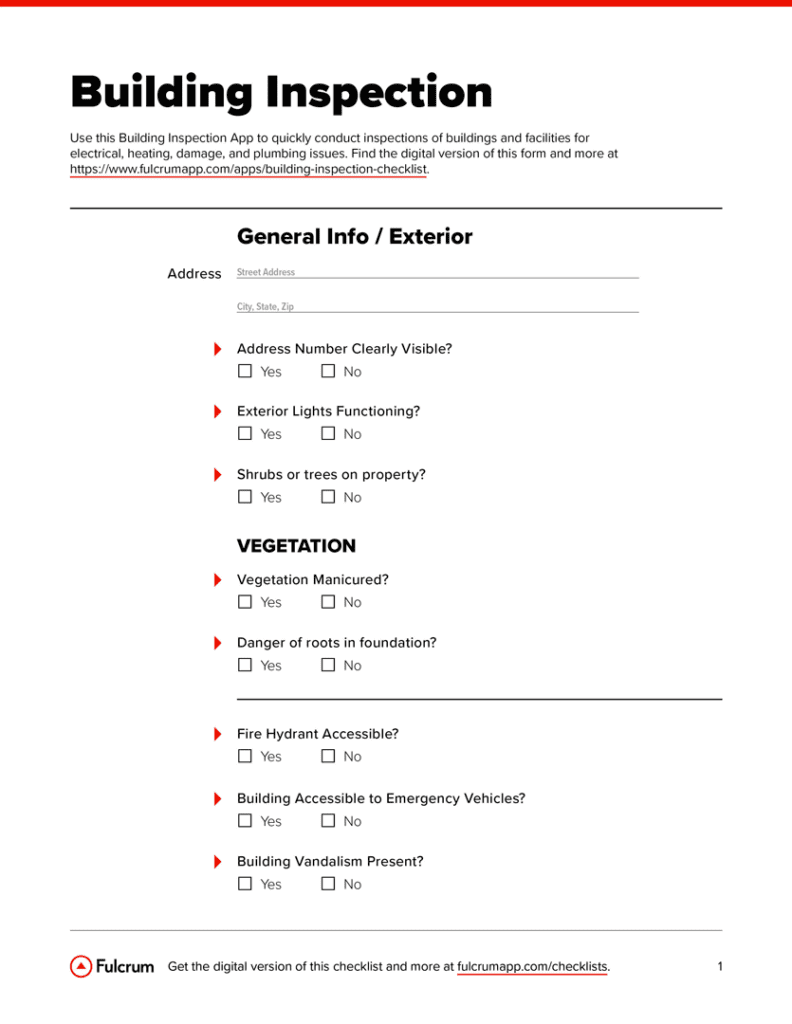

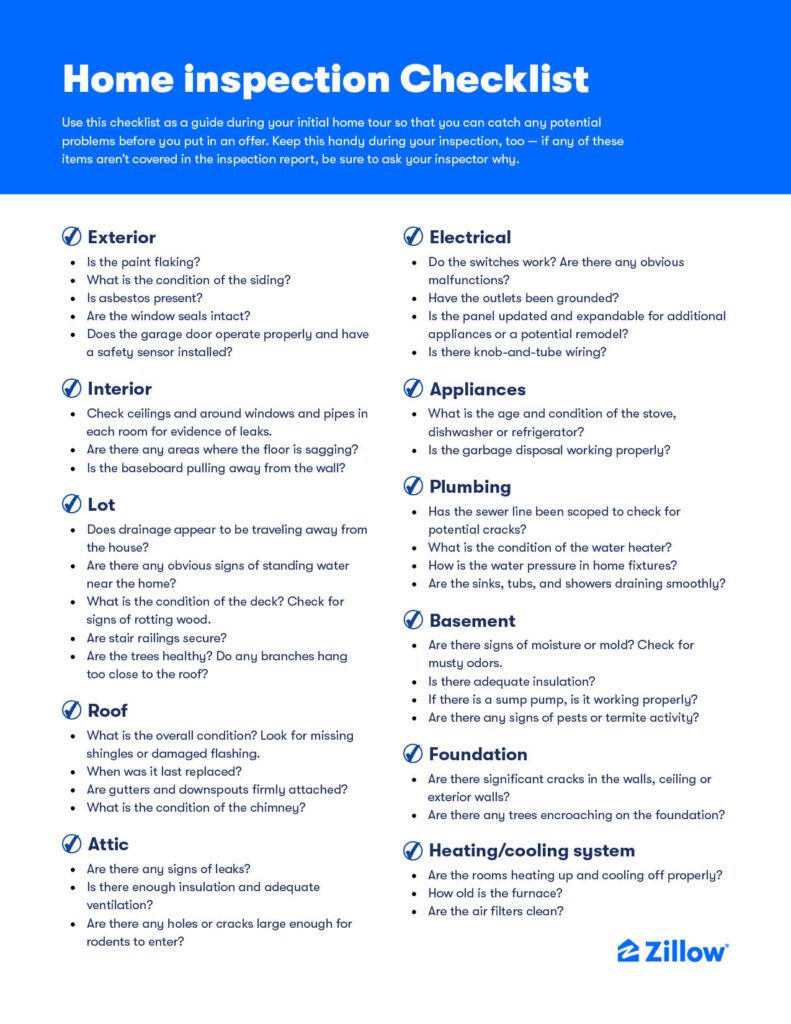

6.2 Home Inspection Checklist

A home inspection checklist is used to evaluate the condition of residential properties. It covers aspects such as the structure, plumbing, electrical systems, heating and cooling systems, and general safety features.

6.3 Vehicle Inspection Checklist

A vehicle inspection checklist assesses the condition, functionality, and compliance of vehicles. It includes items such as tire condition, brake functionality, lights and signals, fluids and lubricants, and overall compliance with vehicle regulations.

6.4 Food Safety Inspection Checklist

A food safety inspection checklist is designed to evaluate food preparation areas, storage facilities, and hygiene practices in food establishments. It includes items such as proper handling of food, temperature control, sanitation procedures, and compliance with food safety regulations.

6.5 Construction Site Inspection Checklist

A construction site inspection checklist focuses on evaluating safety measures, compliance with regulations, and proper construction practices. It includes items such as personal protective equipment usage, fall protection systems, machinery and equipment safety, and adherence to construction codes and standards.

7. Tips for Conducting an Effective Inspection Using a Checklist

Conducting an effective inspection requires careful planning and attention to detail. Here are some tips to help you make the most of your inspection checklist:

7.1 Familiarize Yourself with the Checklist

Before conducting the inspection, take the time to familiarize yourself with the checklist. Understand the objectives, sections, and items to be assessed. This will help you plan your inspection approach and ensure a thorough evaluation.

7.2 Compile Required Tools and Documentation

Gather all the necessary tools, equipment, and documentation needed to perform the inspection. This may include measuring devices, reference documents, safety equipment, or any other specific items relevant to the inspection.

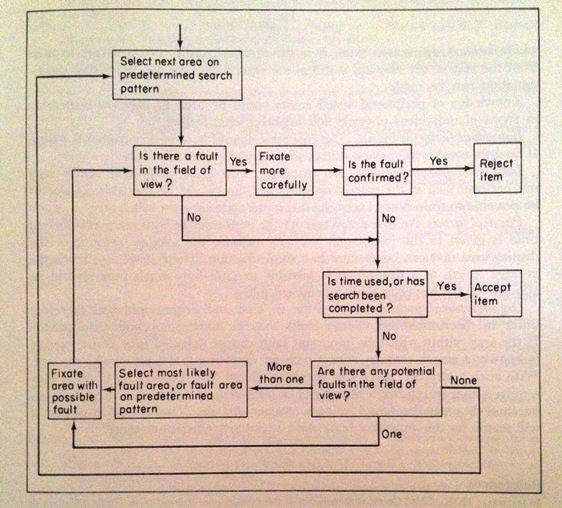

7.3 Follow a Systematic Approach

When conducting the inspection, follow a systematic approach. Start with the first section or item on the checklist and work your way through systematically. This ensures that no items are missed or overlooked during the evaluation process.

7.4 Stay Focused and Thorough

Maintain focus and thoroughness throughout the inspection. Pay attention to detail and observe the subject being inspected carefully. Take notes, measurements, or photographs as necessary to support your findings and observations.

7.5 Note All Relevant Findings

Document all relevant findings, observations, and recommendations within the checklist. Be clear and concise in your notations and avoid making assumptions or speculations. Stick to the facts and provide objective assessments.

7.6 Communicate Observations and Recommendations

After completing the inspection, communicate your findings, observations, and recommendations to relevant stakeholders. Provide a clear and concise summary of the inspection outcomes, highlighting any urgent concerns or areas requiring immediate attention.

8. Common Challenges in Using Inspection Checklists

While inspection checklists offer many benefits, there can be certain challenges associated with their use. Here are some common challenges and how to address them:

8.1 Checklist Design and Structure

Designing an effective checklist can be challenging, as it requires careful consideration of the subject being inspected and its specific requirements. To address this challenge, involve relevant stakeholders in the checklist design process to gather diverse perspectives and ensure that all critical aspects are captured adequately.

8.2 User Compliance

Ensuring user compliance with the inspection checklist can be a challenge. Inspectors may deviate from the checklist or neglect to document their findings accurately. To address this, provide training and clear instructions on the correct use of the checklist. Regularly review and track users’ compliance through quality control measures.

8.3 Keeping Checklists Up-to-Date

Checklists need to be regularly updated to reflect any changes in regulations, standards, or organizational requirements. However, keeping them up-to-date can be a challenge, especially in dynamic environments. To address this challenge, establish a process for reviewing and updating checklists regularly. Assign responsibility to a designated individual or team accountable for maintaining and updating the checklists as needed.

8.4 Adapting to Changing Regulations

Regulations and standards pertaining to inspections often change over time. Adapting to these changes can pose a challenge, especially if the checklist is not regularly reviewed or modified. To overcome this challenge, stay informed about relevant regulations and industry best practices. Establish a process for monitoring and incorporating changes into the checklist promptly.

8.5 Incorporating Technological Advancements

Advancements in technology offer opportunities to enhance the effectiveness and efficiency of inspection checklists. However, incorporating these technological advancements into existing inspection processes can present challenges. To address this, invest in training and education to familiarize inspectors with relevant technologies. Develop partnerships with technology providers and consult experts to ensure seamless integration of technology into the inspection checklist management process.

9. Technology Solutions for Inspection Checklist Management

Technology solutions can significantly improve the management of inspection checklists. Here are some key technology solutions that offer benefits in this regard:

9.1 Digital Checklist Platforms

Digital checklist platforms provide a centralized repository for managing and accessing inspection checklists. They allow for easy creation, modification, and sharing of checklists, ensuring that all inspectors have access to the most up-to-date versions.

9.2 Mobile Applications

Mobile applications enable inspectors to access and conduct inspections using their smartphones or tablets. These applications often come with features such as offline mode, photo capture, and real-time synchronization, enhancing the mobility and efficiency of the inspection process.

9.3 Integration with Other Systems

Technology solutions can often be integrated with other systems such as data management, reporting, or asset management platforms. This integration streamlines the inspection process, enhances data accuracy, and enables seamless information exchange between different systems.

9.4 Real-time Data Capture

Technology solutions offer real-time data capture capabilities, allowing inspectors to enter and record inspection findings immediately. This eliminates the need for manual data entry or transcription, reducing the chances of errors and facilitating quicker analysis and reporting.

9.5 Analytics and Reporting Functions

Technology solutions often come with analytics and reporting functions that enable the analysis and visualization of inspection data. This helps identify trends, patterns, or recurring issues, facilitating data-driven decision-making and continuous improvement efforts.

10. Conclusion

In conclusion, an inspection checklist is a valuable tool that ensures a systematic and thorough assessment of various items, processes, or locations. By effectively using inspection checklists, organizations can enhance consistency, efficiency, accuracy, safety, and compliance in their inspection processes. Creating an effective checklist involves defining the purpose, identifying inspection items, organizing checklist sections, including clear instructions, prioritizing critical items, keeping the checklist concise, and validating and testing the checklist. Despite the challenges associated with using inspection checklists, technology solutions offer valuable enhancements in checklist management, such as digital checklist platforms, mobile applications, integration with other systems, real-time data capture, and analytics and reporting functions. By embracing these technology solutions and implementing best practices, organizations can improve the effectiveness, efficiency, and reliability of their inspection processes.