Moving into a new home means ensuring that every aspect of it is functioning properly, including the HVAC system. HVAC qualification is a crucial step in making sure that your heating, ventilation, and air conditioning system is up to par. During this process, several key components need to be checked thoroughly to ensure optimal performance and efficiency. From inspecting the ductwork to examining the electrical connections, this article will guide you through the essential elements that should be examined during HVAC qualification.

Ductwork

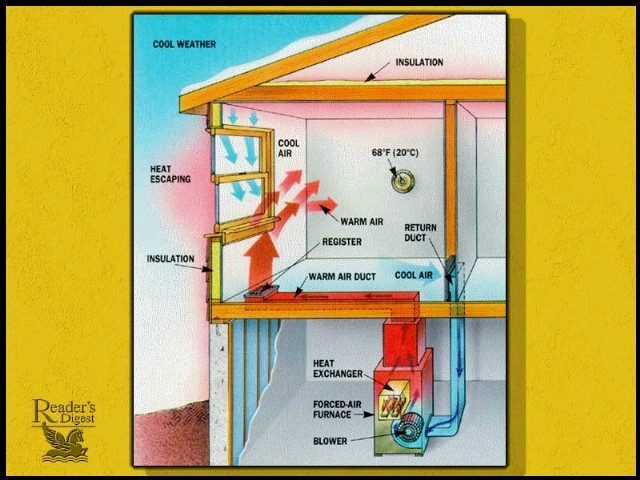

When it comes to HVAC systems, the ductwork plays a crucial role in the proper functioning of the system. Inspecting the insulation of the ductwork is essential to ensure that the conditioned air is not lost during distribution. Proper insulation helps in preventing energy waste and ensures that the air reaches its intended destination efficiently.

Additionally, it is important to check for any air leakage in the ductwork. Even a small leak can lead to a significant loss of air and energy, resulting in inefficient performance. By sealing any leaks, you can ensure that the conditioned air flows smoothly throughout the duct system.

The design and layout of the ductwork also require attention. Proper design and layout ensure that the airflow is evenly distributed, allowing for efficient heating or cooling of the space. It is essential to consider factors such as the size and configuration of the space, as well as the number of air outlets needed to maintain a comfortable environment.

Lastly, the sizing of the ductwork should be examined. A duct system that is too small can restrict airflow, leading to reduced system performance. On the other hand, oversized ducts can result in excessive air leakage and decreased efficiency. The size of the ductwork should be properly calculated to match the requirements of the HVAC system.

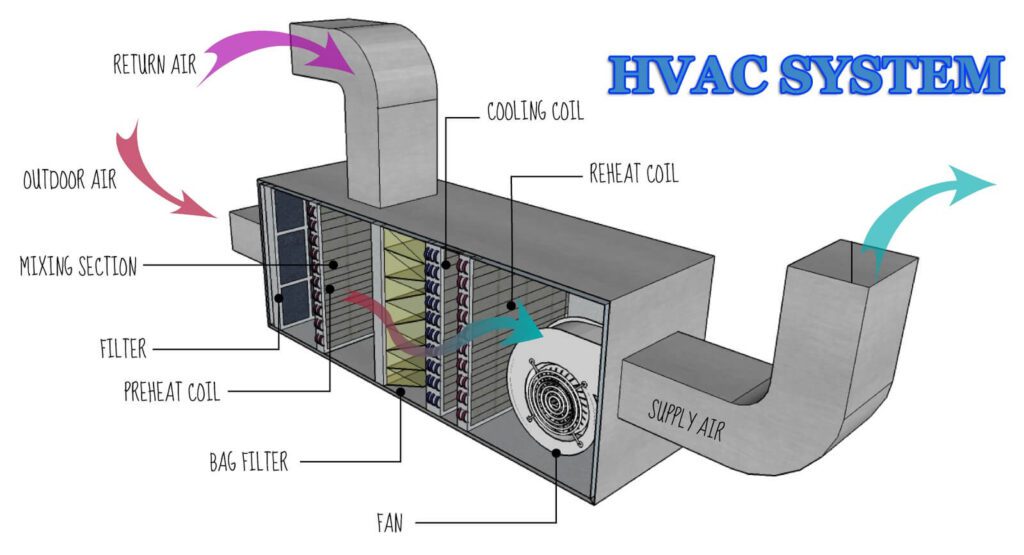

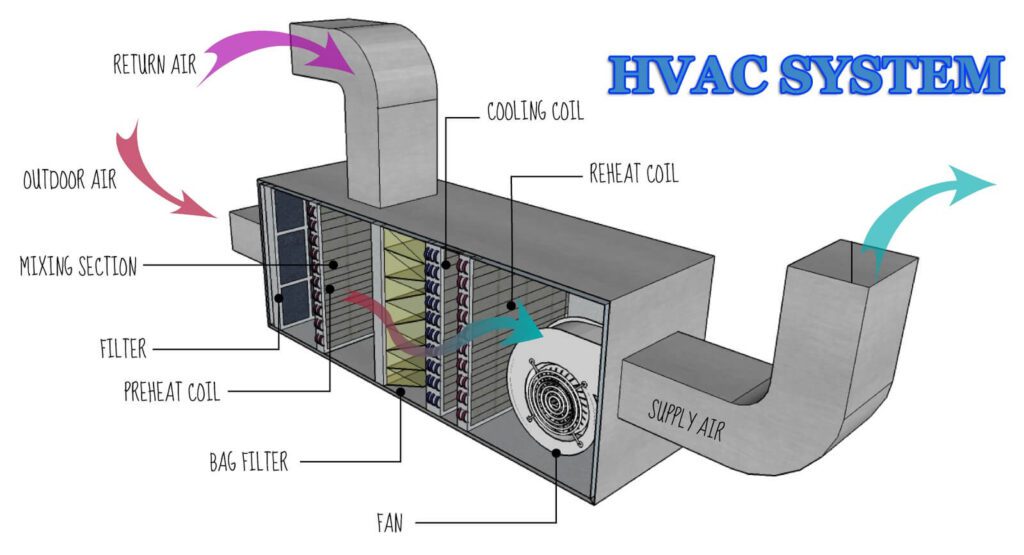

Air Handling Units

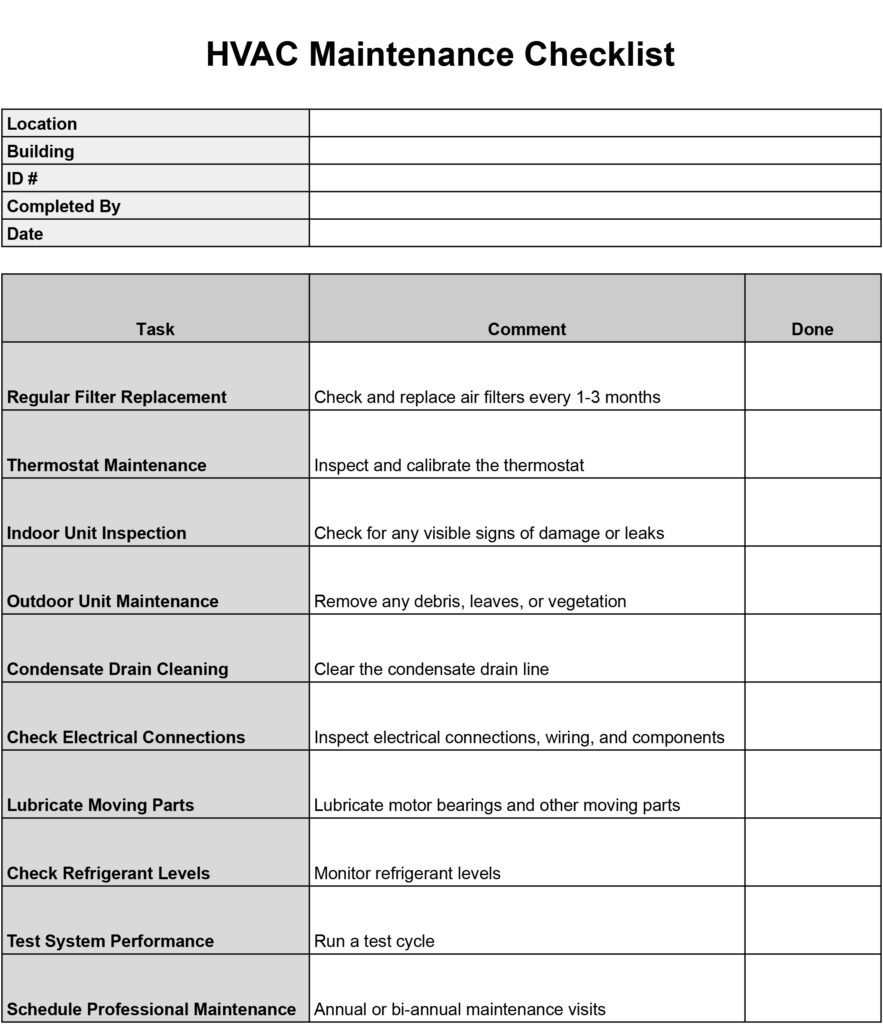

Air handling units (AHUs) are responsible for conditioning and circulating the air within a building. Regular maintenance and inspection of AHUs are crucial to ensure their optimal performance.

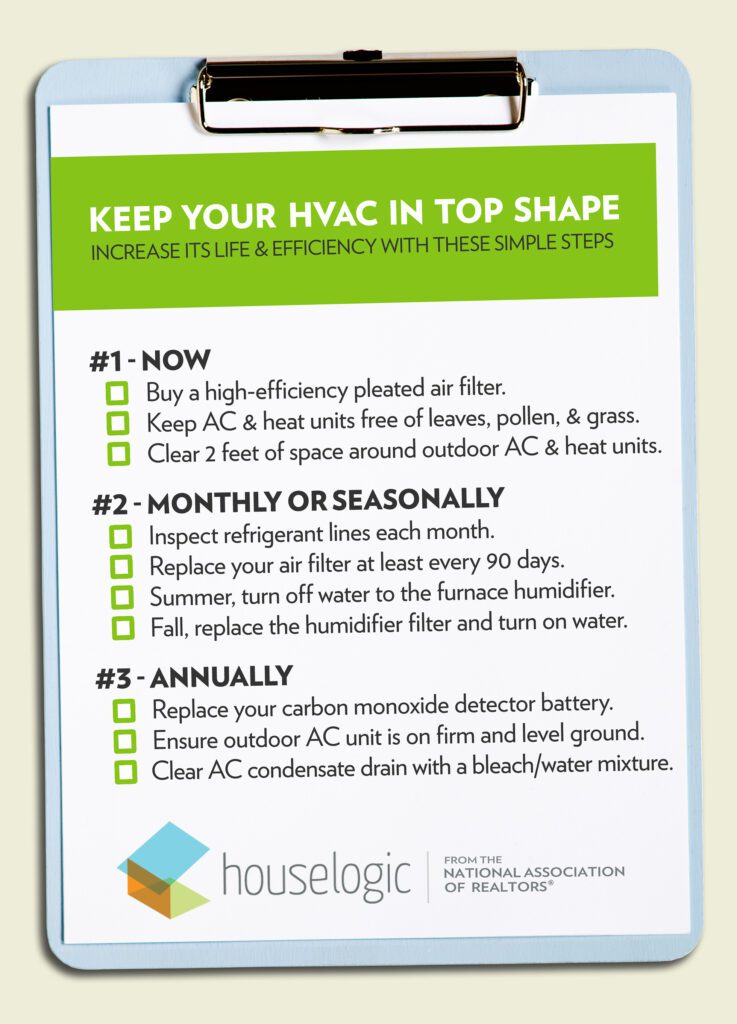

The air filters in the AHUs should be checked and replaced as necessary. Clean air filters ensure that the air entering the system is free from dust, dirt, and other contaminants. Clogged filters can hinder airflow and force the system to work harder, resulting in increased energy consumption.

Fan performance should also be examined. Proper fan operation is vital for efficient air circulation. The fan blades and motor should be inspected for any signs of wear or damage. Lubrication of the fan motor bearings may be required to ensure smooth operation.

Coil cleanliness is another important aspect of AHU maintenance. Dust and debris can accumulate on the coils, reducing their efficiency in heat transfer. Regular cleaning of the coils helps in maintaining optimal performance and preventing energy waste.

Temperature and humidity control are essential for maintaining a comfortable indoor environment. The sensors and controls in the AHU should be calibrated and tested to ensure accurate readings and proper adjustment of temperature and humidity levels.

Heat Exchangers

Heat exchangers are responsible for transferring heat between two fluids without mixing them. Regular cleaning and maintenance of heat exchangers are necessary to ensure their efficiency and longevity.

Cleaning the heat exchangers is essential to remove any dirt, debris, or scaling that may accumulate over time. A build-up of these substances can hinder heat transfer and reduce the efficiency of the heat exchanger. Regular maintenance and cleaning can help prevent such issues and ensure optimal performance.

Pressure and temperature differentials should also be checked during qualification. Proper pressure and temperature differences across the heat exchanger indicate that the heat transfer is occurring as intended. Deviations from the expected differentials may indicate issues such as fouling or scaling, which require attention.

Efficiency is a crucial aspect of heat exchangers. It is important to measure and compare the actual heat transfer efficiency with the expected values. Any significant deviations may indicate the need for maintenance or repairs to improve performance and prevent energy waste.

Leaks or corrosion in heat exchangers can lead to severe efficiency losses and system failures. Visual inspection should be performed to identify any signs of leaks or corrosion. Prompt repair or replacement may be necessary to prevent further damage and ensure proper heat transfer.

Refrigeration System

The refrigeration system is responsible for maintaining low temperatures or cooling in HVAC applications. Several aspects of the system should be checked during qualification to ensure optimal performance.

Compressor operation is a crucial factor in the refrigeration system. The compressor should be inspected for any abnormal noise, vibration, or excessive heat. Proper compressor operation is essential for the efficient circulation of the refrigerant and maintaining the desired cooling effect.

Refrigerant levels should be checked regularly to ensure that they are within the recommended range. Low refrigerant levels can lead to insufficient cooling and increased energy consumption, while excessive levels can cause system malfunctions. Proper monitoring and adjustment of refrigerant levels help maintain optimal performance.

Condenser and evaporator coil cleanliness is important for efficient heat transfer. Regular cleaning of the coils prevents the build-up of dirt, dust, or debris that can hinder heat exchange. Clean coils ensure optimal performance and prevent energy wastage.

Superheat and subcooling are critical parameters in refrigeration systems. Superheat refers to the temperature of the refrigerant vapor above its saturation point, while subcooling refers to the temperature of the refrigerant liquid below its saturation point. Checking and adjusting these values help ensure that the refrigerant is in the correct state for efficient cooling.

Electrical Components

The electrical components of an HVAC system play a vital role in ensuring safe and reliable operation. Several aspects should be examined during qualification to ensure optimal electrical performance.

Voltage and current measurements should be taken to verify that they fall within the specified range. Deviations from the recommended values may indicate issues with the electrical supply or the components. Proper voltage and current levels are crucial for the efficient and safe operation of the HVAC system.

Wiring connections should be inspected for any loose or damaged connections. Loose connections can lead to electrical arcing or overheating, which can be hazardous and result in equipment malfunctions. Proper tightening and repair of wiring connections are important for ensuring a reliable electrical connection.

Control panel functionality should be assessed to ensure that all controls and indicators are functioning properly. The control panel plays a crucial role in monitoring and adjusting the HVAC system’s operation. Any malfunctioning controls should be repaired or replaced promptly to prevent system failures.

Safety devices, such as fuses, circuit breakers, and overload protectors, should be checked to ensure they are in good working condition. These safety devices protect the system from electrical faults or excessive current flow. Regular inspection and testing of safety devices help ensure the safety of both the equipment and the occupants.

Thermostats and Controls

Thermostats and controls regulate the operation of the HVAC system to maintain a comfortable indoor environment. Qualification of these components ensures their accuracy and proper communication with the HVAC equipment.

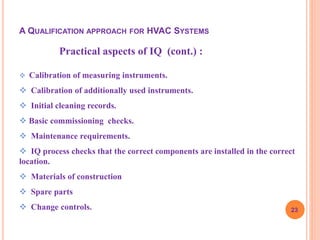

Calibration of thermostats is important to ensure accurate temperature readings and control. Thermostats should be compared with a reference thermometer to verify their accuracy. Accurate thermostats help maintain the desired temperature settings and prevent energy wastage.

Programmable settings should be checked to ensure that they are properly configured according to the building’s occupancy patterns and temperature requirements. Any inconsistencies or errors should be corrected to optimize energy efficiency and occupant comfort.

Sensor accuracy is crucial for the proper functioning of the HVAC system. Sensors measure various parameters such as temperature, humidity, and air quality. Checking the accuracy of these sensors helps ensure that the HVAC system receives accurate input for its operation.

Communication between thermostats and controls and the HVAC equipment should be tested. Proper communication ensures that the HVAC system responds accurately to the set temperature and control inputs. Any communication issues should be addressed promptly to avoid system inefficiencies.

Ventilation

Proper ventilation is essential for maintaining good indoor air quality and occupant comfort. Various factors should be assessed during qualification to ensure optimal ventilation performance.

Ventilation rates should be checked to confirm that they meet the minimum requirements for the building occupants. Insufficient ventilation can lead to poor indoor air quality and discomfort. Adjustments or improvements may be necessary to ensure adequate fresh air supply.

Air quality sensors should be inspected and calibrated to ensure accurate measurements of pollutants or contaminants in the indoor air. Reliable air quality sensors help in maintaining a healthy indoor environment by signaling the need for ventilation adjustments or filtration.

Dampers and louvers control the flow of air in the ventilation system. They should be inspected for any obstructions or mechanical issues that may hinder their operation. Proper functioning of dampers and louvers enables effective control of air distribution and ventilation.

Air distribution should also be evaluated during qualification. The distribution of air should be uniform throughout the space to ensure consistent comfort levels. Any discrepancies or poor airflow should be addressed to optimize the ventilation system’s performance.

Safety Features

Safety features are essential components of an HVAC system to ensure the safety of the equipment and occupants. Several aspects should be examined during qualification to ensure the proper functioning of these safety features.

Emergency shut-off systems should be tested to ensure that they respond promptly in case of emergencies. The shut-off systems help prevent further damage or hazards during critical situations, such as fires or gas leaks.

Carbon monoxide and smoke detectors should be inspected and tested for their sensitivity and responsiveness. These detectors are crucial for early detection and warning of potential fire or gas-related risks. Testing and maintenance of these detectors help ensure occupant safety.

Fire and gas alarms should be checked to verify their functionality and soundness. The alarms should be loud and audible throughout the building to alert occupants in case of emergencies. Regular testing and maintenance of these alarms are important for a prompt response to fire or gas-related incidents.

Pressure relief valves help protect HVAC equipment from excessive pressure and potential explosions. These valves should be inspected to ensure that they are properly installed and in good working condition. Proper pressure relief valves are crucial for preventing equipment failures and ensuring safe operation.

Energy Efficiency

Energy efficiency is a key consideration for HVAC systems to reduce energy consumption and operating costs. Several factors should be evaluated during qualification to optimize energy efficiency.

Insulation levels should be checked to ensure that they meet the recommended standards. Proper insulation prevents heat loss or gain, reducing the load on the HVAC systems and minimizing energy consumption. Inadequate insulation should be addressed to improve energy efficiency.

Thermal bridging refers to the transfer of heat between building components with higher thermal conductivity, bypassing the insulation. Identifying and addressing thermal bridging can significantly enhance energy efficiency by minimizing heat transfer through these conduction pathways.

Efficient equipment selection plays a vital role in energy conservation. Qualified professionals should assess the HVAC system’s components and recommend energy-efficient options for replacement or upgrade. Efficient equipment reduces energy waste and improves overall system performance.

System optimization involves analyzing and fine-tuning the HVAC system’s operation for optimal energy efficiency. This includes adjusting setpoints, scheduling, and controls to match the building’s occupancy patterns and requirements. System optimization helps maximize energy savings while maintaining occupant comfort.

System Documentation

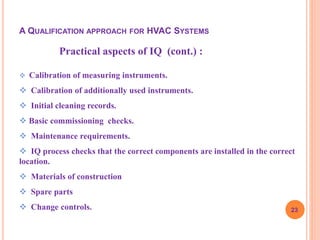

Proper documentation of the HVAC system is crucial for its effective operation and maintenance. Several important documents should be maintained during qualification.

Equipment manuals provide valuable information about the installation, operation, and maintenance requirements of each HVAC component. These manuals serve as a reference for troubleshooting, routine maintenance, and repairs. Keeping equipment manuals readily accessible allows for efficient servicing of the system.

Maintenance records provide a comprehensive history of the HVAC system’s maintenance activities, including inspections, repairs, and replacements. These records help identify trends, track the system’s performance, and plan for future maintenance needs. Well-maintained records ensure that the system receives timely and appropriate maintenance.

As-built drawings are essential for understanding the layout and configuration of the HVAC system. These drawings show the locations of equipment, ductwork, piping, and electrical connections. Accurate as-built drawings assist in troubleshooting, upgrades, or expansions of the system.

Operating procedures outline the steps and guidelines for operating the HVAC system. These procedures include start-up, shutdown, normal operation, and emergency procedures. Well-documented operating procedures ensure safe and efficient operation of the system and help train personnel in its use.

In conclusion, HVAC qualification involves a comprehensive inspection and assessment of various components and aspects of the system. From ductwork to air handling units, heat exchangers, and refrigeration systems, each component plays a crucial role in the proper functioning of the HVAC system. Regular inspection, maintenance, and documentation are vital to ensure optimal performance, energy efficiency, safety, and occupant comfort. By addressing the outlined points during HVAC qualification, professionals can identify and rectify any issues, improving the overall operation and longevity of the HVAC system.