So, you’ve got an upcoming inspection, and the thought of going through a checklist might seem daunting. But worry not! In this article, we’ll guide you on how to prepare yourself for an inspection checklist. Whether it’s for your home, workplace, or any other area, we’ve got you covered with some simple yet effective tips to make sure you’re fully prepared. By following these steps, you’ll tackle that inspection checklist like a pro and ace your next inspection with ease. Let’s get started!

Importance of preparing for an inspection checklist

Understanding the purpose of an inspection checklist

Preparing for an inspection checklist is crucial for ensuring the smooth operation and compliance of any organization. An inspection checklist serves as a comprehensive guide to assess various aspects of the organization, such as the physical environment, documentation, and adherence to standards or regulations. By understanding the purpose of the inspection checklist, you can better comprehend the significance of thorough preparation and its impact on the overall success of the inspection process.

The primary purpose of an inspection checklist is to identify areas of improvement and potential compliance issues within the organization. It allows you to systematically review different aspects, pinpoint potential areas of concern, and take proactive measures to address them before any official inspection takes place. By using an inspection checklist, you can ensure that your organization meets all the necessary requirements and standards set by regulatory bodies, industry best practices, or internal policies.

Recognizing the potential consequences of failing an inspection

Failing an inspection can have severe consequences for an organization. It can lead to financial losses, damage to the organization’s reputation, and even legal consequences. Non-compliance with regulations or standards could result in hefty fines, license suspensions, or in extreme cases, closure of the organization. Additionally, failed inspections can erode customer trust and confidence, leading to a loss of business and potential revenue. Therefore, recognizing the potential consequences of failing an inspection is vital in understanding the importance of thorough preparation and ensuring compliance.

Understanding the inspection checklist

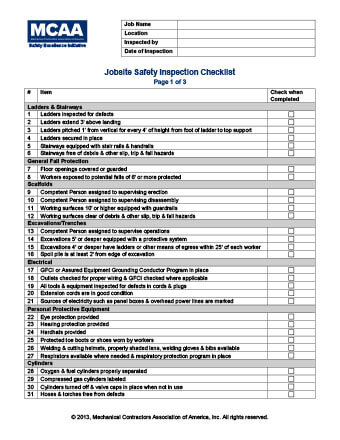

Familiarizing yourself with the items on the checklist

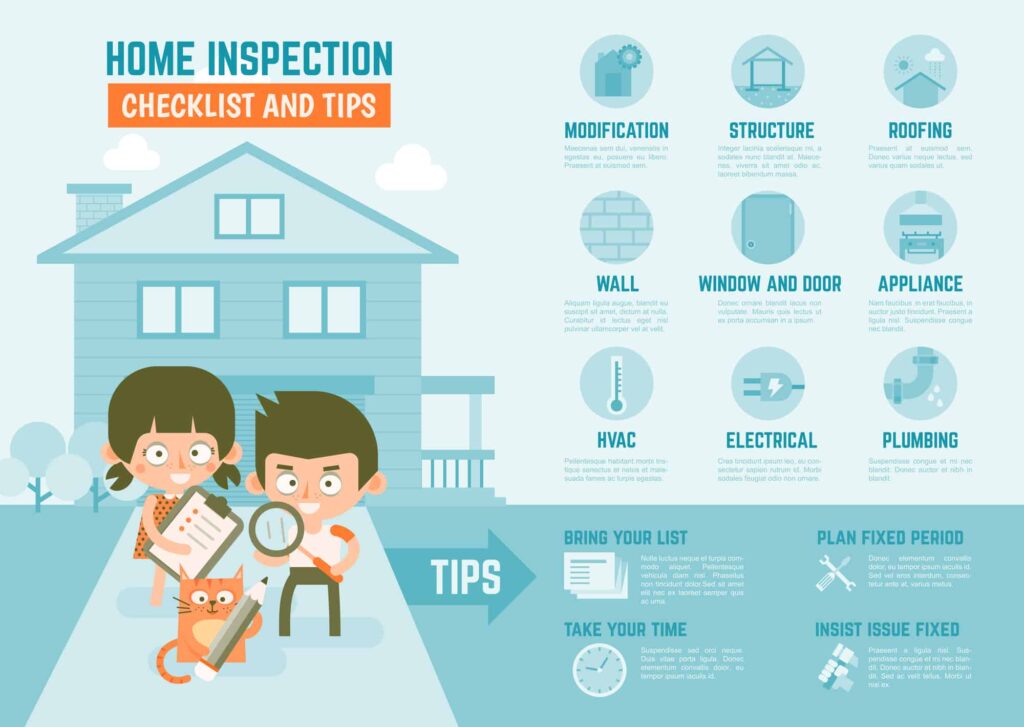

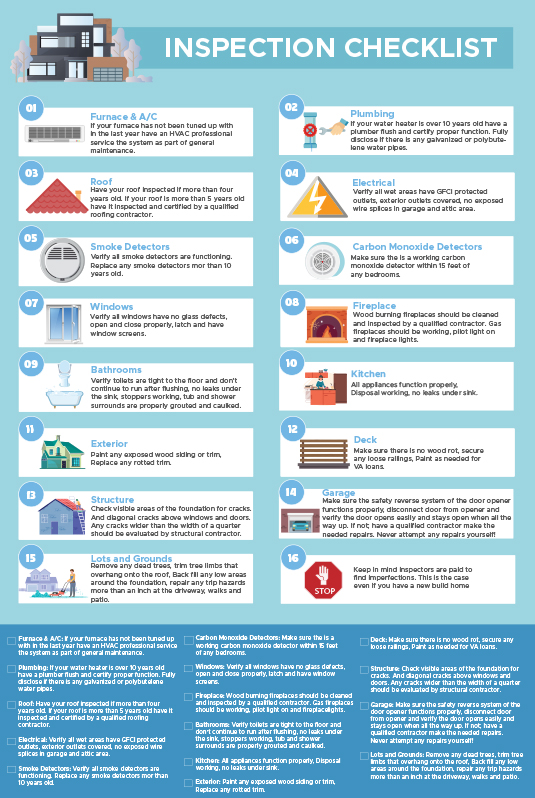

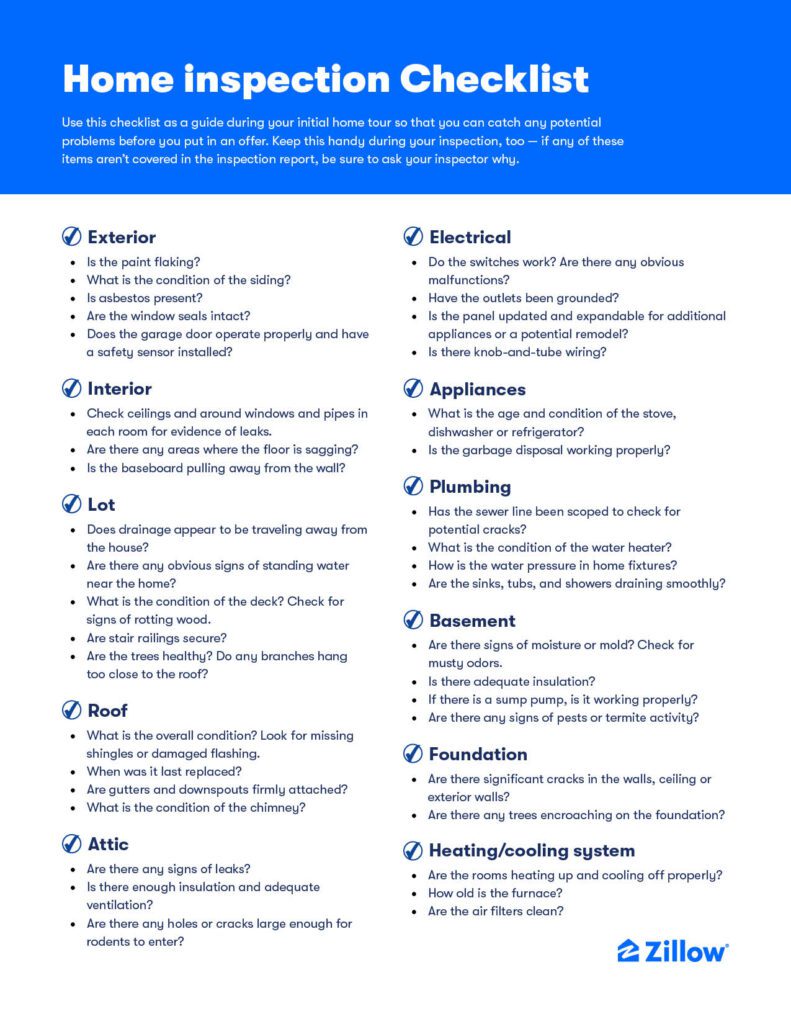

Before preparing for an inspection checklist, it is essential to thoroughly familiarize yourself with the items included in the checklist. These items typically cover a wide range of requirements, including cleanliness and organization, documentation, equipment functionality, and adherence to specific standards or regulations. By becoming familiar with each item, you can better assess the organization’s current state and identify areas that may require improvement or attention. Take the time to review each item carefully to ensure a comprehensive understanding.

Identifying any specific requirements or standards

In addition to the general items on the inspection checklist, it is crucial to identify any specific requirements or standards that apply to your organization. These could be industry-specific regulations, certifications, or internal policies and procedures. By understanding these specific requirements, you can tailor your preparation efforts to address them adequately. This may involve conducting additional research, consulting relevant authorities, or seeking guidance from industry experts to ensure compliance.

Reviewing past inspection reports

Reviewing past inspection reports can provide valuable insights into areas that have previously been identified as deficient or non-compliant. Analyzing these reports allows you to identify recurring issues and patterns that need to be addressed. By reviewing past inspection reports, you can gain a better understanding of the organization’s strengths and weaknesses, providing you with a solid foundation for your preparation efforts.

Gathering necessary documentation

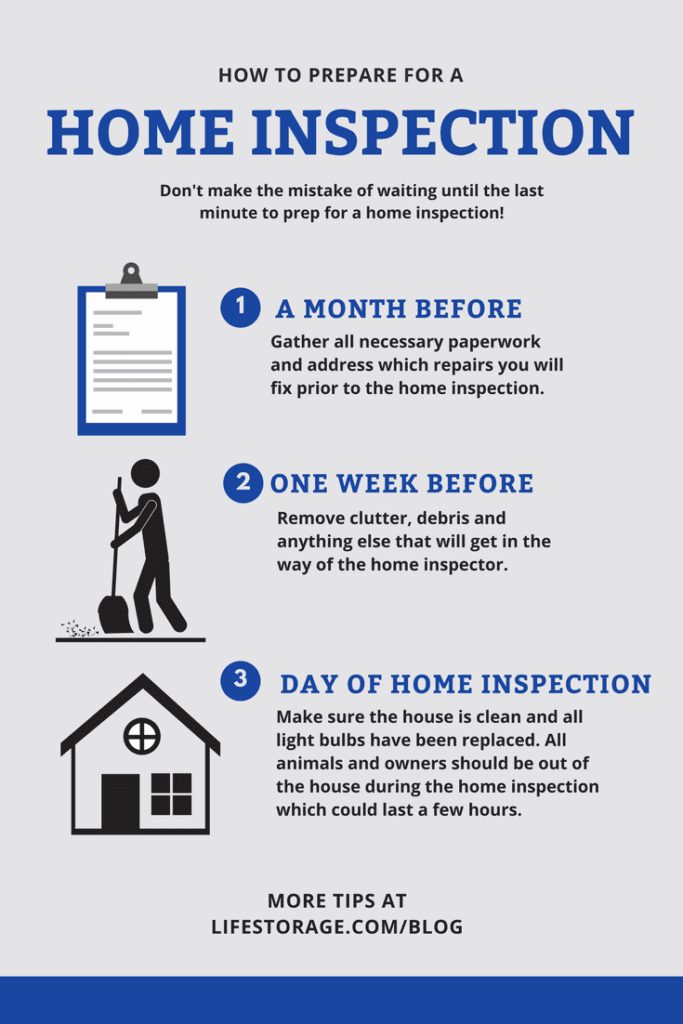

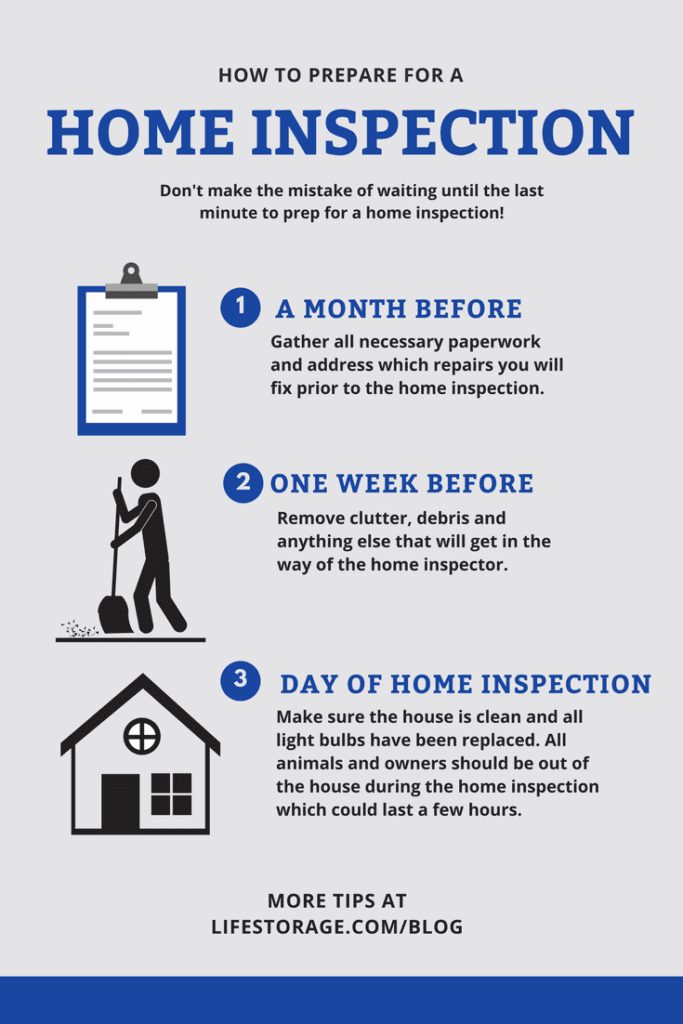

Identifying the required documents

As part of the inspection process, you will likely be required to provide various documents to validate the organization’s compliance. These documents may include permits, licenses, certifications, safety data sheets, training records, inspection reports, and maintenance records, among others. It is essential to identify the specific documents required for the inspection checklist to ensure you have them readily available.

Ensuring the documents are up to date

To ensure a smooth inspection process, it is crucial to ensure that all the required documents are up to date. This includes validating the expiration dates of licenses, certifications, and permits, as well as updating any outdated information on training records or maintenance logs. Failing to have up-to-date documents can raise concerns during the inspection and may result in non-compliance findings, even if the organization meets all the requirements in practice.

Organizing and categorizing the documents

Organizing and categorizing the required documents can save time and make the inspection process more efficient. Create a logical system for storing and retrieving documents, ensuring that they are easily accessible when needed. Consider implementing a digital document management system to streamline the organization and retrieval of necessary documents. Categorizing the documents based on their relevance to different aspects of the inspection checklist can further enhance the preparation process.

Conducting a self-inspection

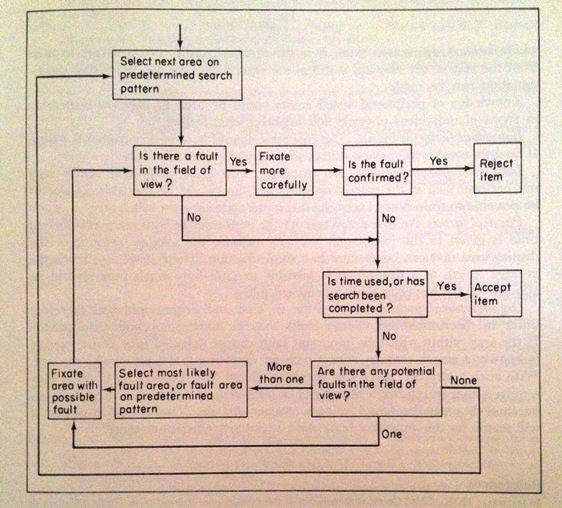

Performing a comprehensive inspection prior to the official inspection

Conducting a self-inspection is a proactive approach to identify and address any potential issues or non-compliance before the official inspection takes place. Performing a comprehensive inspection allows you to simulate the official inspection process, ensuring that all necessary steps and requirements are met. This self-inspection helps uncover any shortcomings, giving you the opportunity to rectify them and improve overall compliance.

Addressing any identified issues or non-compliance

During the self-inspection, it is crucial to address any identified issues or non-compliance promptly. Take immediate action to rectify the problems, whether they involve infrastructure, processes, documentation, or employee compliance. By addressing these issues proactively, you can significantly reduce the risk of them being flagged during the official inspection. This not only ensures compliance but also demonstrates your commitment to maintaining high standards.

Documenting the self-inspection process and findings

Documenting the self-inspection process and findings is vital for several reasons. Firstly, it serves as evidence of your efforts to comply with requirements and improve the organization’s operations. Secondly, it provides a reference point for future inspections, enabling you to track progress and measure the effectiveness of corrective actions taken. Finally, documentation can be used as a communication tool to demonstrate your commitment to compliance with internal stakeholders, employees, and external auditors.

Creating an action plan

Identifying areas needing improvement

After conducting a self-inspection, it is essential to identify areas needing improvement. This can be done by analyzing the findings and comparing them to the requirements outlined in the inspection checklist. By identifying these areas, you can focus your efforts on implementing specific measures to address the deficiencies. It is crucial to prioritize the areas that pose the highest risk or have the most significant impact on compliance or operational efficiency.

Developing corrective measures

Once the areas needing improvement are identified, it is time to develop corrective measures. These measures should be practical, feasible, and tailored to the specific deficiencies identified. It may involve updating standard operating procedures, implementing additional training programs, improving equipment maintenance protocols, or introducing new processes to ensure compliance. It is essential to involve relevant stakeholders and subject matter experts in the development of corrective measures to ensure their effectiveness.

Setting clear goals and deadlines

To ensure accountability and progress, it is crucial to set clear goals and deadlines for implementing the corrective measures. Clear goals provide guidance and direction, ensuring that efforts are aligned with the desired outcome. Deadlines help create a sense of urgency and ensure timely completion of necessary actions. By setting clear goals and deadlines, you can maintain focus, measure progress, and demonstrate your commitment to continuous improvement during the inspection process.

Training and communication

Ensuring employees are aware of the inspection checklist

One of the critical factors in preparing for an inspection checklist is ensuring that all employees are aware of its existence and the expectations it sets. Communicate the purpose and relevance of the inspection checklist to all employees, highlighting its importance in maintaining compliance, quality, and safety. Ensure that employees understand their roles and responsibilities in relation to the checklist and the specific requirements it entails.

Providing necessary training and resources

To facilitate compliance, it is essential to provide employees with the necessary training and resources. Training programs should cover the requirements outlined in the inspection checklist, ensuring that employees understand not only what is expected but also how to achieve it. Provide access to relevant documentation, standard operating procedures, and training materials to empower employees to meet the checklist requirements effectively.

Facilitating open communication channels

Establishing open communication channels is vital during the preparation process. Encourage employees to ask questions, seek clarification, and provide feedback. This open communication ensures that everyone is well-informed and engaged in the inspection preparation efforts. It also helps identify any potential areas of concern that may have been overlooked, allowing for timely resolution and improvement.

Engaging in continuous improvement

Analyzing the results of past inspections

To improve the effectiveness of future inspections, it is crucial to analyze the results of past inspections. Identify trends, recurring issues, and areas of significant improvement from previous inspections. Use this analysis as a basis for identifying areas to focus on during the current preparation process. By continuously learning and leveraging past inspection results, you can demonstrate a commitment to ongoing improvement and strive for excellence in each inspection cycle.

Implementing feedback and recommendations

Feedback and recommendations received from previous inspections, internal auditors, or industry experts should be taken into account during the preparation process. These recommendations often provide valuable insights into areas that may require attention or improvement. By implementing feedback and recommendations, you demonstrate responsiveness and a proactive attitude towards continuous improvement.

Regularly updating and improving processes

Continuous improvement should not be limited to the inspection preparation process alone. Regularly review and update your processes, standard operating procedures, and practices to ensure ongoing compliance and efficiency. Leverage industry best practices, feedback from inspections, and emerging research to identify opportunities for improvement. By regularly updating and improving processes, you can stay ahead of changing regulations, enhance operational efficiency, and maintain a culture of continuous improvement within your organization.

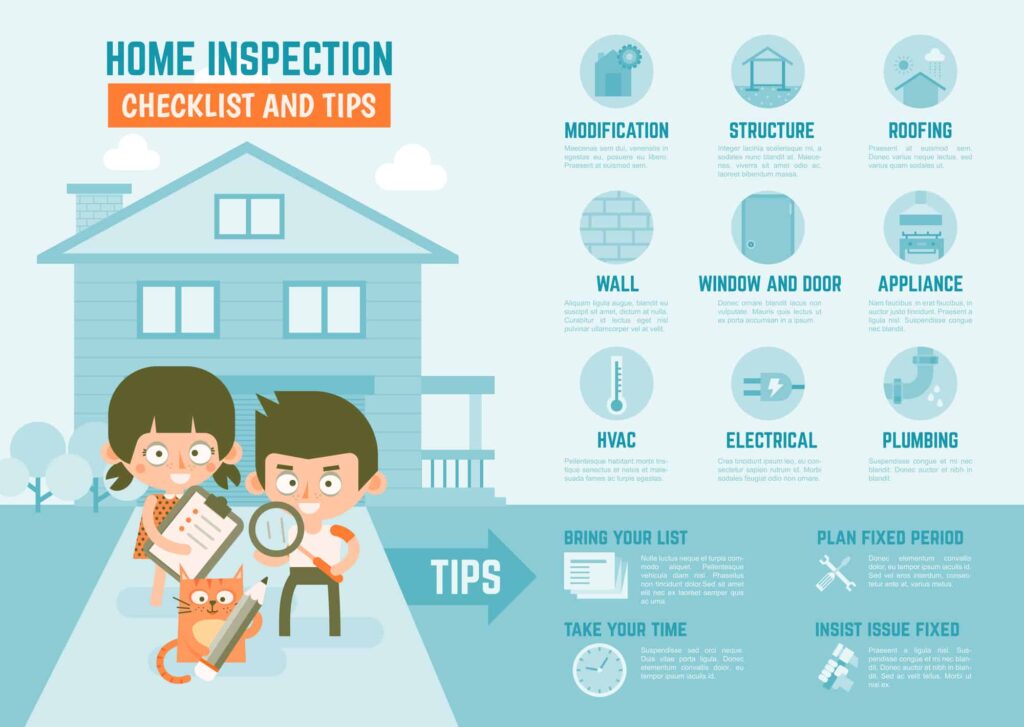

Preparing the physical environment

Ensuring cleanliness and organization

Preparing the physical environment involves ensuring that cleanliness and organization standards are maintained. Regularly clean and sanitize the premises, paying attention to high-traffic areas, restrooms, and food preparation areas. Maintain adequate waste management procedures and practices to prevent environmental hazards and health risks. Additionally, ensure that storage areas, workspaces, and equipment are organized in a manner that promotes ease of access, safety, and efficiency.

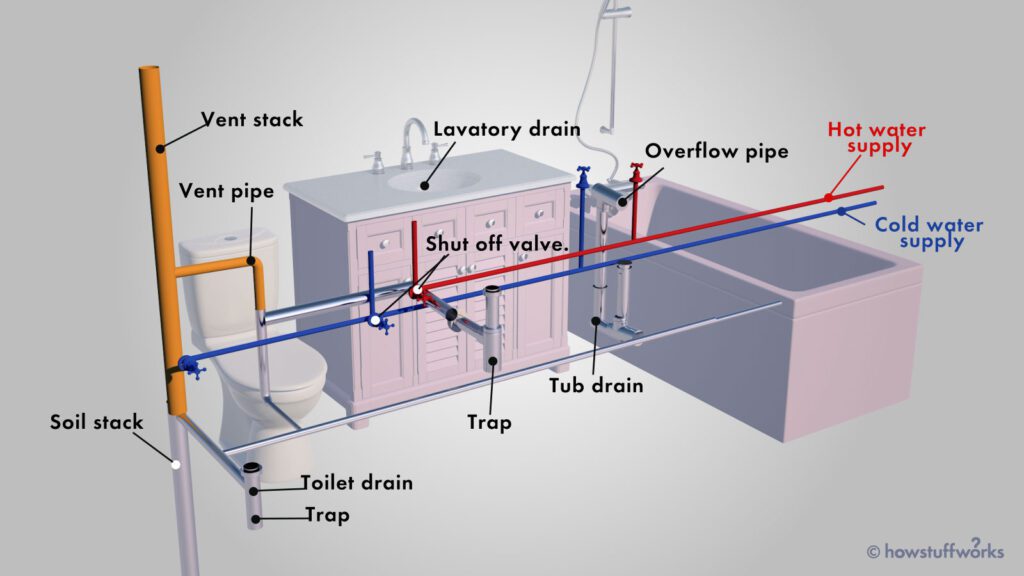

Checking equipment functionality and safety

Equipment functionality and safety are critical aspects of preparation for an inspection checklist. Regularly inspect and maintain equipment to ensure it is in proper working order and adheres to relevant safety standards. Test equipment regularly and address any identified issues promptly. Ensure that appropriate safety measures are in place, such as emergency exits, fire extinguishers, first aid kits, and personal protective equipment (PPE), as required.

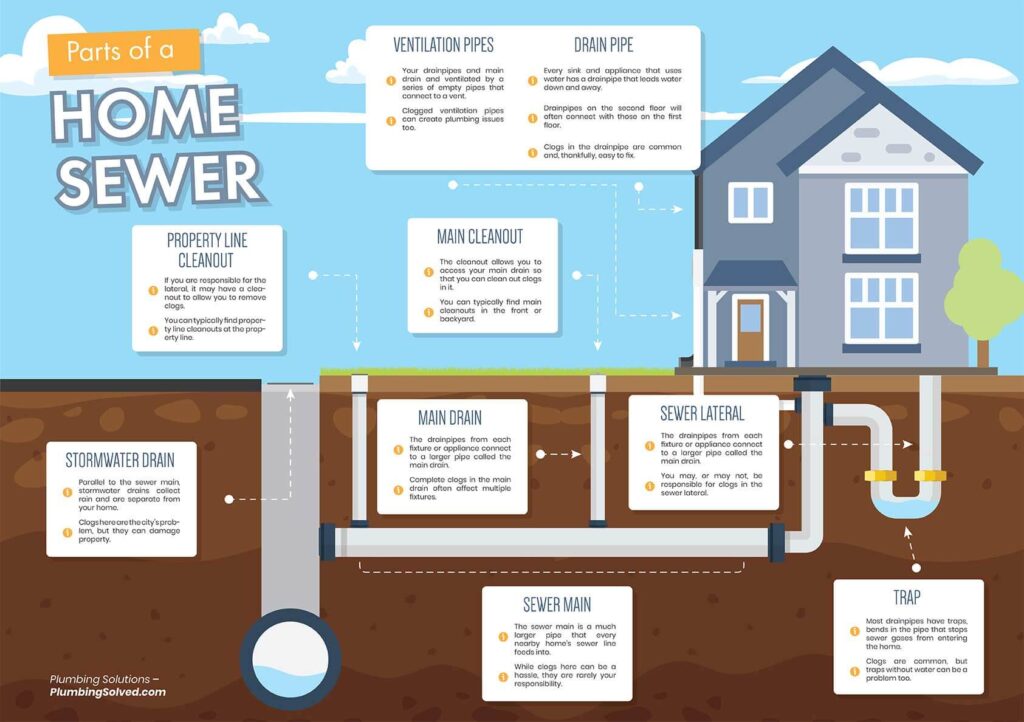

Addressing any environmental concerns

Environmental concerns, such as waste management, pollution prevention, and energy consumption, should also be addressed during the preparation process. Implement environmentally friendly practices, such as recycling programs, energy-saving initiatives, and water conservation measures. Ensure compliance with environmental regulations, such as proper disposal of hazardous materials. By addressing environmental concerns, you not only demonstrate your commitment to sustainable practices but also minimize potential environmental hazards.

Coordinating with relevant personnel

Assigning roles and responsibilities to team members

To ensure effective preparation for an inspection checklist, assign clear roles and responsibilities to team members. Identify individuals who will take the lead in specific areas, such as documentation, self-inspection, corrective actions, or employee training. Clearly communicate these roles and expectations to all team members and ensure they have the necessary resources and support to fulfill their responsibilities effectively.

Coordinating schedules and timelines

Coordinate schedules and timelines to ensure that all preparation activities are completed in a timely manner. Develop a comprehensive timeline that incorporates all necessary tasks, such as gathering documentation, conducting self-inspections, implementing corrective measures, and employee training. By maintaining a well-coordinated schedule, you can avoid last-minute rushes and ensure a smooth and efficient preparation process.

Collaborating with internal and external stakeholders

Collaboration with internal and external stakeholders is key to successful inspection preparation. Engage relevant departments or teams within the organization, such as quality assurance, maintenance, or environmental health and safety, to ensure their involvement in the preparation process. Seek external guidance or assistance, such as consultants or industry experts, to validate your preparation efforts and provide additional insights. By fostering collaboration, you can leverage the expertise and resources of all stakeholders to achieve optimal results during the inspection process.

Maintaining a confident and positive mindset

Staying calm and composed during the inspection

Maintaining a confident and positive mindset is essential during the inspection process. It is natural to feel nervous or anxious, but remember that thorough preparation has been done, and you have taken proactive measures to ensure compliance. Stay calm and composed, demonstrating your confidence in the organization’s ability to meet the inspection checklist requirements. A confident demeanor can positively influence the overall impression of the inspection team and contribute to a smoother inspection process.

Responding professionally to any queries or concerns

During the inspection, the inspection team may raise queries, concerns, or point out potential non-compliance issues. Responding professionally to these inquiries is crucial. Be prepared to provide accurate and honest responses, acknowledging any identified issues or shortcomings. Avoid becoming defensive or argumentative, as this may create a negative impression. Instead, demonstrate your commitment to rectifying any issues and providing necessary documentation or evidence to support your responses.

Viewing the inspection as an opportunity for improvement

Lastly, view the inspection as an opportunity for improvement rather than a mere compliance exercise. Embrace the feedback and recommendations provided by the inspection team, recognizing them as valuable insights to enhance your organization’s operations. Use the findings from the inspection to further refine your processes, procedures, and training programs. By viewing the inspection as an opportunity for improvement, you can foster a culture of continuous learning and growth within your organization.