In this article, you will discover the lifespan of vermiculite – an incredible and versatile material used in various industries. If you have ever wondered how long this mineral can endure, you’re about to find out. From insulation to horticulture, vermiculite has proven its longevity and efficacy. So, let’s dig in and uncover the impressive durability of vermiculite!

What is Vermiculite

Definition of Vermiculite

Vermiculite is a naturally occurring mineral that is often used as an insulation material due to its excellent thermal properties and fire resistance. It is formed through the weathering and hydration of certain minerals, resulting in a lightweight and expandable material that has a unique layered structure.

Properties of Vermiculite

Vermiculite has several desirable properties that make it an ideal choice for various applications. Firstly, it has excellent thermal insulation properties, which means it can trap heat and prevent its transfer to the surrounding environment. This property makes it highly effective in retaining warmth and reducing energy consumption. Additionally, vermiculite is resistant to high temperatures and can withstand extreme heat without deteriorating or losing its insulating capabilities.

Moreover, vermiculite is a highly absorbent material, capable of holding moisture and preventing the formation of mold and mildew. Its ability to retain water also makes it useful for horticultural purposes, as it can provide a consistent source of moisture to plants. Vermiculite is also non-combustible, making it a safe choice for insulation in residential, commercial, and industrial buildings.

Factors Affecting Vermiculite Lifespan

Quality of Vermiculite

The quality of vermiculite used in insulation plays a vital role in its overall lifespan. Higher quality vermiculite tends to have better resistance to degradation over time. It is crucial to choose vermiculite from reputable sources that adhere to strict quality control measures. Poor quality vermiculite may have impurities or irregularities that can impact its durability and lifespan.

Exposure to Moisture

Exposure to moisture is a significant factor that can affect the lifespan of vermiculite. While vermiculite has the capacity to absorb and retain moisture, prolonged exposure to excessive moisture can lead to its degradation. It is important to ensure proper moisture control in areas where vermiculite insulation is installed, especially in basements or areas prone to water leaks.

Temperature and Heat

Vermiculite is known for its excellent resistance to high temperatures, but extreme heat over an extended period can still impact its lifespan. Long-term exposure to temperatures above its recommended threshold can cause the vermiculite to lose its insulating properties or become brittle. Proper temperature regulation and avoiding excessive exposure to heat sources are crucial for maintaining the longevity of vermiculite insulation.

Chemical Exposure

Certain chemicals and substances can have a detrimental effect on vermiculite. Exposure to chemicals, such as solvents, strong acids, or alkaline solutions, can lead to the breakdown of the vermiculite structure and compromise its insulation effectiveness. It is essential to avoid exposing vermiculite insulation to any chemicals that could potentially cause damage or degradation.

Frequency of Use

The frequency of use can also impact the lifespan of vermiculite. High-traffic areas or places where vermiculite is frequently disturbed, such as attics or crawl spaces, may experience more wear and tear. Continuous movement or disturbance of the insulation can lead to its compaction, reducing its effectiveness over time. Minimizing unnecessary traffic or disturbances in areas with vermiculite insulation can help extend its lifespan.

Maintenance and Care

Proper maintenance and care are crucial for maximizing the lifespan of vermiculite insulation. Regular inspections should be conducted to check for any signs of deterioration, damage, or moisture accumulation. Promptly addressing any issues found during inspections can prevent further damage and prolong the life of the vermiculite insulation. Ensuring that the insulation is not compressed, maintaining proper airflow, and avoiding any physical damage are essential aspects of maintaining vermiculite insulation.

Expected Lifespan of Vermiculite

Industry Standards

The expected lifespan of vermiculite insulation can vary depending on factors such as quality, installation, and maintenance. In general, industry standards suggest that properly installed and maintained vermiculite insulation can last for several decades. However, it is important to consider the specific conditions and factors mentioned above that can affect its lifespan.

Residential Use

In residential settings, vermiculite insulation can last anywhere from 20 to 30 years or even longer with appropriate care. Regular inspections and maintenance can help identify any issues early on and ensure the insulation remains effective for an extended period. It is important to note that the lifespan of vermiculite insulation in residential buildings may vary depending on the climate, exposure to moisture, and other individual factors.

Commercial Use

The lifespan of vermiculite insulation in commercial buildings can also vary, but it generally ranges from 20 to 40 years. Commercial buildings may have different demands and conditions compared to residential structures, so proper maintenance, regular inspections, and adherence to industry standards are essential to maximize the lifespan of vermiculite insulation.

Signs of Vermiculite Aging

Changes in Appearance

As vermiculite insulation ages, it may undergo changes in appearance that indicate the deterioration of its properties. The color of the vermiculite may darken or become discolored, and its texture may become coarser. These visual changes can suggest the need for further inspection and potential replacement of the insulation.

Loss of Insulation Properties

One of the primary signs of vermiculite aging is the loss of its insulation properties. Over time, the insulation effectiveness of vermiculite may diminish, resulting in decreased energy efficiency and increased heating or cooling costs. If the insulation no longer performs its intended function, it may be necessary to consider replacing it.

Decay and Degradation

Vermiculite insulation can decay or degrade over time, especially if exposed to unfavorable conditions. Signs of decay may include crumbling, powdery consistency, or the development of a damp or musty smell. These signs indicate that the vermiculite insulation has reached the end of its lifespan and should be replaced promptly.

Increased Fragility

As vermiculite insulation ages, it can become more fragile and prone to breaking or disintegrating when touched or disturbed. This fragility can be observed when handling the insulation during inspections or maintenance activities. Increased fragility is a clear indication that the vermiculite insulation has deteriorated and is in need of replacement.

Best Practices for Extending Vermiculite Lifespan

Proper Installation

Proper installation of vermiculite insulation is crucial for ensuring its long lifespan. It is essential to follow manufacturer guidelines and industry best practices during installation. Correctly placing and distributing the vermiculite insulation in the desired areas, without compressing it excessively, will prevent potential issues and promote its longevity.

Regular Inspections

Regular inspections are vital for detecting any signs of aging or deterioration in vermiculite insulation. Inspections should be conducted by qualified professionals who can assess the condition of the insulation and identify any areas that may need attention. Early identification of problems can help prevent further damage and extend the lifespan of the insulation.

Controlling Moisture Levels

Proper moisture control is crucial for maintaining the integrity of vermiculite insulation. Implementing measures to prevent excessive moisture accumulation, such as ensuring proper ventilation and addressing any leaks promptly, can help preserve the insulation’s effectiveness and prevent premature aging.

Avoiding Chemical Exposure

Protecting vermiculite insulation from exposure to chemicals is essential for extending its lifespan. Preventing contact with substances that can cause degradation or damage, such as solvents or strong acids, will help maintain its insulation properties. Proper handling and storage can also prevent accidental exposure to harmful chemicals.

Appropriate Storage and Handling

Proper storage and handling of vermiculite insulation can significantly impact its lifespan. Storing the insulation in a dry and well-ventilated area, away from direct sunlight and extreme temperatures, will help prevent any unnecessary degradation. Care should also be taken during handling to avoid excessive compression or physical damage to the insulation.

Alternatives to Vermiculite

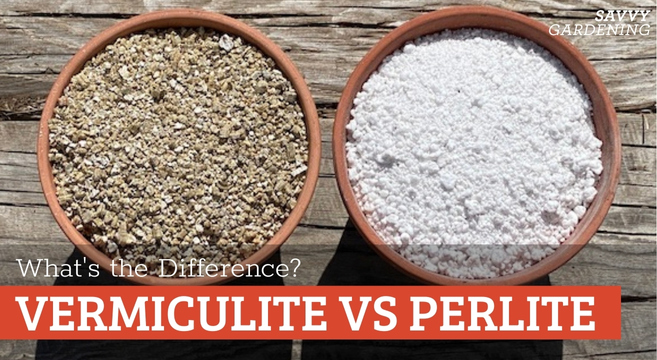

Perlite

Perlite is a popular alternative to vermiculite in insulation applications. It is a lightweight volcanic glass that has been heated to expand into a porous and insulating material. Perlite offers similar thermal insulation properties to vermiculite and is resistant to fire, moisture, and pests. However, it is important to note that perlite may have slightly different properties and applications compared to vermiculite, so consulting with professionals is advisable when considering alternatives.

Expanded Clay

Expanded clay, also known as lightweight expanded clay aggregate (LECA), is another alternative to vermiculite. It is made from clay that is heated to create lightweight, spherical pellets with excellent insulation properties. Expanded clay is durable, resistant to fire and pests, and provides good moisture regulation. It is commonly used in horticulture, construction, and geotechnical applications.

Expanded Polystyrene

Expanded polystyrene (EPS) foam is a widely used insulation material. It is made from expanded polystyrene beads that are fused together to form rigid panels or molded shapes. EPS insulation offers excellent thermal insulation properties, is lightweight, and resistant to moisture and pests. It is commonly used in both residential and commercial constructions.

Rockwool

Rockwool, also known as mineral wool or stone wool, is an inorganic insulation material made from molten rock. The molten rock is spun into fibers and then pressed into various forms, such as batts, boards, or loose-fill. Rockwool insulation provides excellent thermal and acoustic insulation properties, is fire-resistant, and offers good moisture resistance. It is commonly used in buildings, industries, and horticulture.

Vermiculite and Asbestos

Historical Use

In the past, some vermiculite insulation products were contaminated with asbestos, a naturally occurring mineral that can cause serious health risks when inhaled. This contamination occurred due to the presence of asbestos in the natural deposits of vermiculite. Asbestos-containing vermiculite insulation was primarily used in residential and commercial buildings from the 1920s to the late 1980s.

Health Risks

Exposure to asbestos can lead to severe health risks, including lung diseases such as asbestosis and mesothelioma. Asbestos fibers released from deteriorating insulation can become airborne and be inhaled, posing a significant health hazard. It is crucial to handle and manage vermiculite insulation with caution, especially if there is a concern about possible asbestos contamination.

Asbestos Testing

To determine if vermiculite insulation contains asbestos, it is recommended to have it tested by a qualified professional. Asbestos testing involves collecting samples of the insulation and sending them to an accredited laboratory for analysis. Testing should be conducted by trained professionals who follow proper safety protocols to minimize any potential exposure risks.

How to Dispose of Vermiculite

Safety Precautions

When disposing of vermiculite insulation, it is important to take necessary safety precautions to minimize the risk of exposure to asbestos or other potentially harmful substances. It is recommended to wear appropriate personal protective equipment, such as disposable coveralls, gloves, and a respirator, when handling vermiculite insulation. Additionally, sealing off the work area and ensuring proper ventilation can further reduce the risk of spreading any contaminants.

Local Regulations

Before disposing of vermiculite insulation, it is essential to research and comply with local regulations regarding its proper disposal. Different regions may have specific guidelines or requirements for handling and disposing of insulation materials, especially if they are suspected to contain asbestos. Contacting local authorities or professional asbestos removal services can provide guidance on the proper disposal methods.

Professional Assistance

In cases where vermiculite insulation is suspected to contain asbestos, it is highly recommended to seek professional assistance for its removal and disposal. Asbestos removal professionals have the necessary training, equipment, and knowledge to safely handle and dispose of asbestos-containing materials. They can ensure that the removal process is performed according to regulations and guidelines, minimizing any potential health risks.

Conclusion

In conclusion, vermiculite insulation can provide excellent thermal and fire resistance properties, making it a popular choice for various applications. The lifespan of vermiculite insulation depends on several factors such as quality, exposure to moisture, temperature, chemical exposure, frequency of use, and maintenance. Proper installation, regular inspections, moisture control, and avoiding chemical exposure are essential in extending the lifespan of vermiculite insulation. Additionally, if vermiculite insulation is suspected to contain asbestos, it is important to adhere to safety precautions, follow local regulations, and seek professional assistance for its disposal. By understanding the expected lifespan and proper handling of vermiculite insulation, you can ensure its effectiveness and contribute to a safe and energy-efficient environment.