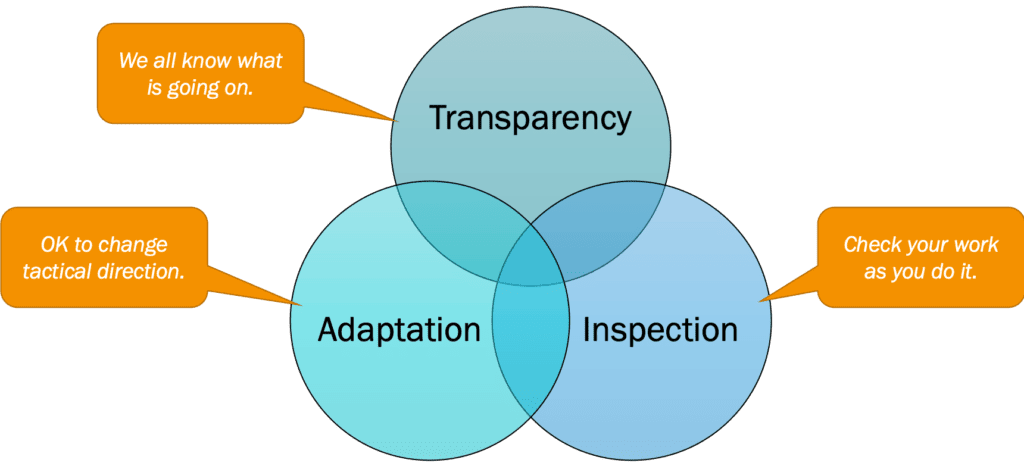

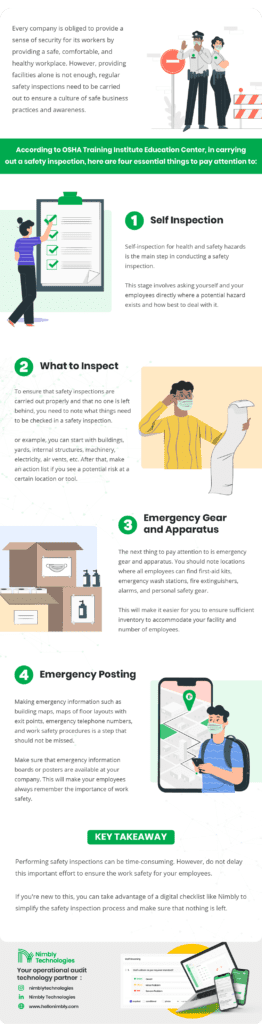

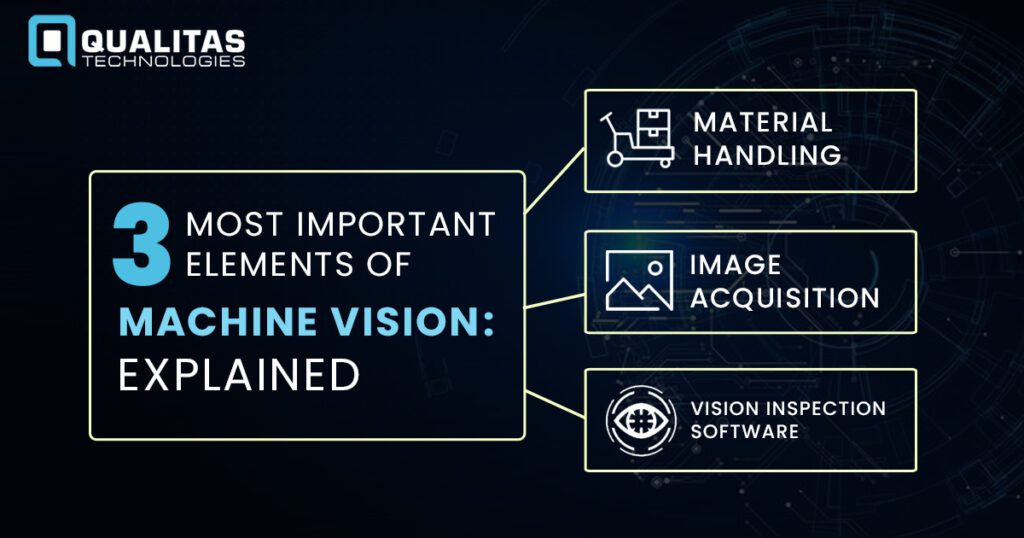

In the world of inspection, there are three key elements that play a crucial role in ensuring quality and safety. These elements define the process and guide inspectors in their assessment. By understanding and implementing these three components effectively, inspections become much more efficient and reliable. So, let’s explore what these elements are and how they contribute to the overall inspection process.

Overview of Inspection

Inspection is a systematic process that involves the careful examination, measurement, and evaluation of various objects, systems, or processes. It is an essential practice across industries to ensure quality control, identify potential issues, and maintain safety standards. Inspections can vary in scope and purpose, but they generally involve visual examination, measurement and testing, and documentation and reporting.

Definition of Inspection

Inspection refers to a thorough examination or evaluation of something to determine its condition, quality, or compliance with specific standards or requirements. It can involve the assessment of physical attributes, performance characteristics, or adherence to regulatory guidelines. Inspections are typically conducted by trained professionals who possess the knowledge and skills required to identify any deviations, defects, or deficiencies.

Importance of Inspection

Inspection plays a crucial role in various aspects of business and everyday life. It helps ensure that products, processes, and systems meet certain standards, thereby ensuring customer satisfaction and safety. By conducting inspections, companies can prevent costly mistakes, minimize risks, and avoid potential hazards. Timely and comprehensive inspections also contribute to enhanced quality control, increased operational efficiency, and improved overall performance.

Purpose of Inspection

The primary purpose of inspection is to assess the condition or performance of an object, system, or process to identify any issues, defects, or areas for improvement. Inspections serve as a means of quality assurance, enabling organizations to maintain consistency, reliability, and compliance with relevant regulations or industry standards. Additionally, inspections help establish a benchmark for evaluating and monitoring ongoing operations, ensuring that corrective actions can be taken if necessary.

Element 1: Visual Examination

Definition of Visual Examination

Visual examination is a fundamental element of the inspection process that involves the thorough observation and scrutiny of an object, system, or process using the naked eye or appropriate visual aids. It focuses on identifying any visible defects, irregularities, or anomalies that may affect the overall quality, safety, or functionality of the subject being inspected.

Types of Visual Inspection

Visual inspections can be categorized into different types depending on their purpose and the nature of the object or system being examined. Some common types of visual inspections include:

-

External inspections: Assessing the exterior or surface features of an object or structure, such as the appearance, texture, or color.

-

Internal inspections: Examining the internal components, structures, or systems of an object, such as pipelines, machinery, or electronic devices.

-

Functional inspections: Evaluating the operation or functionality of an object or system, checking for proper functioning and identifying any observable issues.

-

Comparative inspections: Comparing the inspected object or system against established standards or reference samples to identify any deviations or inconsistencies.

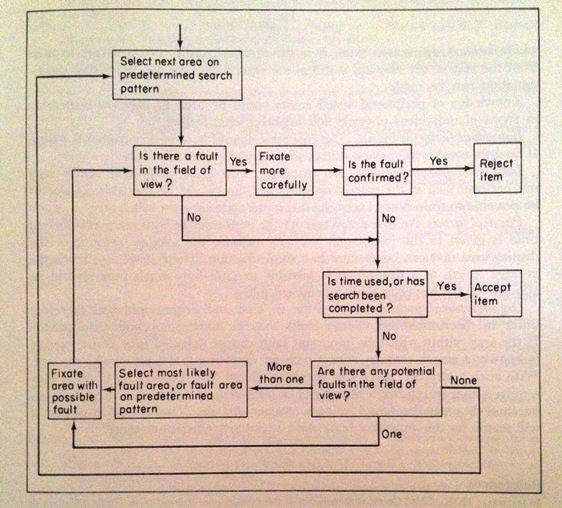

Steps involved in Visual Examination

Visual examination typically follows a systematic approach to ensure thoroughness and accuracy. The steps involved may include:

-

Preparation: Gathering relevant information, documentation, and inspection tools or aids. This step also involves ensuring proper lighting, accessibility, and safety precautions.

-

Observation: Carefully observing the subject being inspected, noting any visible defects, damages, or abnormalities. This step may involve documenting the findings through written notes, photographs, or videos.

-

Analysis: Assessing the observed features or issues in relation to applicable standards or requirements. This step may involve using reference materials, guidelines, or expert knowledge to determine the significance or severity of the observed defects.

-

Reporting: Documenting the inspection findings, including the identified defects, recommended actions, and any supporting evidence. The report should be clear, concise, and accessible to relevant stakeholders.

Element 2: Measurement and Testing

Importance of Measurement and Testing

Measurement and testing are integral components of the inspection process as they provide quantitative or qualitative data to assess the performance, conformity, or quality of the subject being inspected. Accurate measurements and rigorous testing help identify any deviations from desired specifications, enabling corrective actions to be taken before further issues arise.

Types of Measurement and Testing

Measurement and testing can encompass different techniques and methodologies depending on the nature of the inspection and the objectives to be achieved. Some common types of measurement and testing methods include:

-

Dimensional measurement: Assessing the physical dimensions, sizes, or geometrical characteristics of an object using measurement tools such as calipers, micrometers, or coordinate measuring machines (CMMs).

-

Non-destructive testing (NDT): Evaluating the structural integrity, material properties, or internal conditions of an object without causing damage, typically using techniques such as ultrasonic testing, magnetic particle inspection, or radiographic testing.

-

Performance testing: Assessing the functional or operational capabilities of a system or equipment under various conditions, such as stress testing, endurance testing, or environmental testing.

-

Chemical analysis: Examining the composition or chemical properties of substances or materials to ensure compliance with specific requirements or standards. This may involve using techniques such as spectroscopy, chromatography, or titration.

Process of Measurement and Testing

The process of measurement and testing involves several key steps to ensure accuracy, reliability, and repeatability of results. These steps may include:

-

Selection of appropriate measurement or testing methods based on the inspection requirements and objectives.

-

Calibration of measurement instruments or testing equipment to establish accuracy and traceability.

-

Preparation of the subject being inspected, including proper cleaning, setup, or installation to ensure accurate measurements and reliable testing.

-

Execution of the measurement or testing procedure according to established protocols or standards. This step may involve recording measurements, observations, or data in a systematic manner for analysis and interpretation.

-

Analysis and interpretation of the measurement or testing results, comparing them against relevant standards, specifications, or reference values. This step may involve statistical analysis, trend analysis, or expert judgment.

-

Documentation and reporting of the measurement or testing findings, including any deviations, uncertainties, or recommendations. The report should be clear, concise, and accessible to relevant stakeholders.

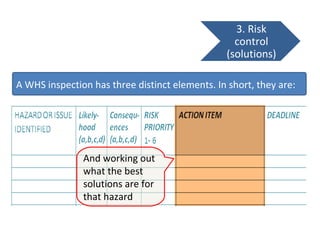

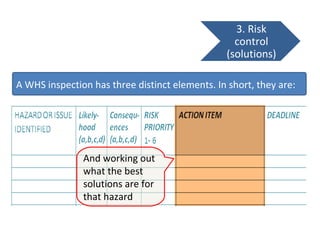

Element 3: Documentation and Reporting

Purpose of Documentation and Reporting

Documentation and reporting are vital aspects of the inspection process as they enable the preservation, communication, and interpretation of inspection findings and recommendations. Proper documentation ensures that inspection results can be reviewed, analyzed, and acted upon by relevant stakeholders, facilitating effective decision-making and corrective actions.

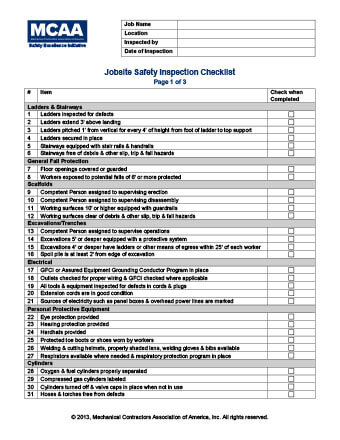

Components of Documentation and Reporting

The documentation and reporting of inspections should include several essential components to ensure clarity, completeness, and relevance. These components may include:

-

Identification details: Clearly identifying the inspected subject, including its name, unique identifiers, location, or relevant specifications.

-

Inspection objectives: Stating the purpose or goals of the inspection, including specific requirements or standards that need to be assessed or met.

-

Inspection scope: Defining the boundaries or extent of the inspection, including any limitations or exclusions that may affect the interpretation of findings.

-

Inspection methods: Describing the specific methods, techniques, or tools used during the inspection, including any calibration or standardization procedures followed.

-

Findings and observations: Documenting the observed defects, issues, or non-conformities identified during the inspection, including their description, location, severity, or potential impact.

-

Recommendations: Providing actionable recommendations or suggestions for corrective actions, improvements, or further investigations based on the inspection findings. These recommendations should be specific, feasible, and prioritized.

-

Supporting evidence: Including any photographs, videos, measurements, test results, or other relevant documentation that supports the inspection findings or justifies the recommendations.

Methods of Documentation and Reporting

Documentation and reporting can be done using various methods, depending on the nature of the inspection and the intended audience. Some common methods of documentation and reporting include:

-

Written reports: Preparing comprehensive inspection reports that summarize the findings, recommendations, and supporting evidence in a structured and organized manner. These reports may include tables, graphs, or diagrams to facilitate understanding.

-

Digital documentation: Using electronic tools or software to record, store, and manage inspection data and reports. This method allows for easy access, searchability, and sharing of information, enhancing collaboration and communication among stakeholders.

-

Visual documentation: Using photographs, videos, or sketches to capture and illustrate the observed defects, issues, or conditions. Visual documentation can help convey information more effectively and enable better understanding of the inspection findings.

-

Oral presentations: Delivering verbal presentations or briefings to communicate the inspection findings, recommendations, and supporting evidence to relevant stakeholders. This method allows for interactive discussions, immediate clarification, and personalized communication.

Common Challenges in Inspection

Time Constraints

One of the most common challenges in the inspection process is dealing with time constraints. Inspections often have to be conducted within specific deadlines to ensure timely decision-making, maintenance, or compliance. However, limited time may affect the thoroughness and accuracy of the inspection, potentially leading to overlooked defects or incomplete assessments. To mitigate this challenge, efficient planning, prioritization, and allocation of resources are essential. It is important to establish clear timelines, streamline inspection procedures, and leverage technology or automation whenever possible.

Resource Limitations

Inspections may face resource limitations in terms of manpower, equipment, or budget. Insufficient resources can hinder the effectiveness and efficiency of inspections, making it challenging to cover a large scope, provide adequate training to inspectors, or invest in advanced inspection technologies. To address this challenge, organizations should prioritize resource allocation based on risk assessments, establish effective communication channels, and seek partnerships or collaborations with external entities or experts when necessary.

Accuracy and Consistency

Maintaining accuracy and consistency in inspections can be a significant challenge, especially when multiple inspectors or teams are involved, or when subjective judgment is required. Differences in interpretation, subjective biases, or human errors can affect the reliability and comparability of inspection results. To overcome this challenge, organizations should establish clear inspection protocols, provide comprehensive training to inspectors, encourage peer reviews or quality control checks, and leverage standardized techniques, methods, or measurement tools whenever possible.

Benefits of Effective Inspection

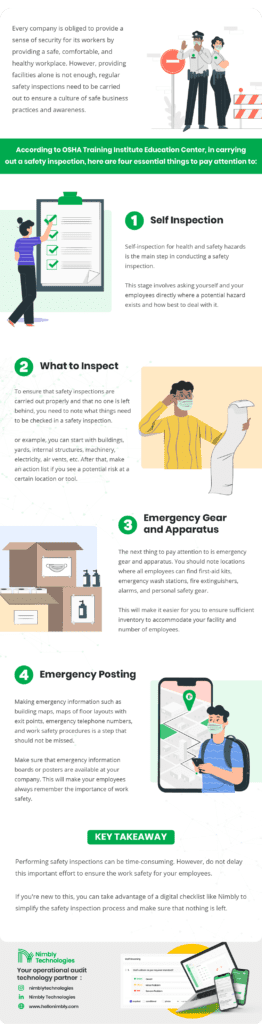

Early Identification of Issues

One of the key benefits of effective inspection is the early identification of issues or potential problems. By regularly inspecting objects, systems, or processes, organizations can proactively detect and address defects, deviations, or failures before they escalate into more significant or costly problems. Early identification allows for prompt corrective actions, minimizing disruptions, improving operational efficiency, and reducing potential risks or failures. This proactive approach helps organizations save time, resources, and money in the long run.

Enhanced Quality Control

Effective inspection practices significantly contribute to enhanced quality control across industries. By systematically examining, measuring, and evaluating various aspects of products, processes, or systems, organizations can ensure that they consistently meet the required standards, specifications, or customer expectations. Inspections provide valuable feedback on production or operation processes, enabling organizations to identify areas for improvement, optimize performance, and enhance overall quality. This focus on quality control helps foster customer satisfaction, build trust, and maintain a competitive edge in the market.

Improved Safety Standards

Inspections play a vital role in ensuring and improving safety standards in various industries. By thoroughly assessing the safety features, compliance with regulations, or potential hazards, inspections help identify and mitigate risks that could lead to accidents, injuries, or other adverse events. Safety inspections can cover aspects such as equipment, infrastructure, facilities, or working conditions, allowing organizations to implement necessary measures to prevent incidents, promote a safe work environment, and fulfill their legal obligations. The commitment to safety not only protects individuals but also preserves the reputation and credibility of organizations.

Difference between Inspection and Testing

Defining Inspection

Inspection and testing are two distinct yet interconnected processes. Inspection, as discussed earlier, refers to the careful examination, measurement, and evaluation of objects, systems, or processes to determine their condition, quality, or compliance with specific standards or requirements. Inspection is typically performed through visual examination, measurement and testing, and documentation and reporting to assess the overall performance and identify any issues or defects. Inspection focuses on the identification and assessment of observable characteristics, often involving subjective judgment and expert knowledge.

Understanding Testing

In contrast, testing refers to a more specific and controlled procedure that involves the examination or experimentation of a subject under specific conditions or scenarios to evaluate its performance, characteristics, or behavior. Testing often includes subjecting the object or system to various stresses, loads, or environmental conditions to determine its limits, functionality, or reliability. Testing is typically more quantifiable and measurable than inspection, relying on objective data, statistical analysis, or pass/fail criteria to assess the performance or conformity of the subject being tested.

Key distinctions between Inspection and Testing

While inspection and testing share similarities in terms of assessing the quality or compliance of objects or systems, they have distinct characteristics and objectives:

-

Objective: Inspection focuses on identifying visible defects, non-conformities, or anomalies, while testing aims to evaluate performance, functionality, or adherence to specific criteria.

-

Subjectivity: Inspection often involves subjective judgment and interpretation of observed characteristics, while testing relies on objective data and measurable metrics.

-

Scope: Inspection is typically broader in scope, encompassing visual examination, measurement, and documentation, while testing is more targeted, focusing on specific performance or functional aspects.

-

Methodology: Inspection is often based on established standards, requirements, or guidelines, with a greater emphasis on qualitative assessment, while testing may involve creating specific test plans, scenarios, or protocols, with a greater emphasis on quantitative analysis.

-

Purpose: Inspection provides a comprehensive evaluation of the overall condition or quality of an object or system, while testing aims to validate or verify specific characteristics, capabilities, or performance requirements.

While inspection and testing are distinct processes, they are often complementary in ensuring quality control, identifying issues, and maintaining regulatory compliance. Both play crucial roles in various industries and sectors, contributing to overall product or process improvement.

Inspection Tools and Technologies

Visual Inspection Tools

Visual inspection tools play a critical role in facilitating thorough and accurate examination of objects, systems, or processes. These tools help inspectors identify, document, and communicate any visible defects, anomalies, or areas of concern. Some commonly used visual inspection tools include:

- Magnifying glasses: Used to magnify small details or surfaces for better visual examination.

- Flashlights and spotlights: Provide additional lighting to enhance visibility in dimly lit areas or confined spaces.

- Borescopes: Allow inspection of areas that are difficult to access, such as internal components of machinery or pipelines.

- Cameras: Help capture images or videos of the inspected objects for documentation, analysis, or future reference.

Measurement and Testing Equipment

Measurement and testing equipment are essential for obtaining accurate and reliable data during inspections. These tools enable inspectors to quantify various aspects, assess performance, and ensure compliance with relevant standards or specifications. Common measurement and testing equipment include:

- Calipers: Used for dimensional measurements such as length, diameter, or thickness.

- Micrometers: Provide precise measurements of small dimensions, tolerances, or clearances.

- Multimeters: Allow for electrical measurements, including voltage, current, resistance, or continuity.

- Pressure gauges: Assess pressure levels in systems or equipment to ensure safe and efficient operation.

- Force gauges: Measure forces or loads applied to objects or structures for validation or adjustment purposes.

Digital Inspection Solutions

Digital inspection solutions leverage advanced technologies to enhance the efficiency, accuracy, and accessibility of inspections. These solutions automate various aspects of the inspection process, providing real-time data, seamless collaboration, and comprehensive reporting. Some examples of digital inspection solutions include:

- Inspection mobile apps: Enable inspectors to record, document, and synchronize inspection data using smartphones or tablets. These apps often provide features such as checklist-based inspections, photo and video documentation, and real-time reporting or sharing.

- Inspection management software: Facilitate the planning, scheduling, and tracking of inspections, ensuring compliance with regulatory requirements or internal procedures. These software solutions typically provide functionalities for managing inspection records, generating reports, and analyzing trends or patterns.

- Remote inspection technologies: Allow for remote or virtual inspections using video conferencing, live streaming, or augmented reality. These technologies enable experts or inspectors to remotely guide or supervise inspections in real-time, enhancing efficiency, reducing costs, and minimizing travel requirements.

The use of appropriate inspection tools and technologies can significantly enhance the effectiveness, speed, and accuracy of inspections, contributing to improved quality control, streamlined processes, and better decision-making.

Types of Inspections

Preventive Inspections

Preventive inspections, also known as proactive inspections or preventive maintenance inspections, aim to identify and address potential issues or risks before they lead to failure or disruption. These inspections are conducted at regular intervals, focusing on the proactive assessment of objects, systems, or processes to prevent unexpected breakdowns, accidents, or costly repairs. Preventive inspections help organizations implement timely maintenance, adjust or replace components, and optimize performance, ultimately reducing downtime and improving reliability.

Routine Inspections

Routine inspections refer to regular, scheduled assessments of objects, systems, or processes to ensure ongoing performance, compliance, or safety. These inspections follow established procedures and checklists, often based on industry best practices or regulatory requirements. Routine inspections are typically conducted at predetermined intervals or frequencies, helping organizations detect deviations, wear and tear, or degradation over time. By identifying and addressing issues early, routine inspections contribute to the overall reliability, longevity, and efficiency of assets, systems, or operations.

Specialized Inspections

Specialized inspections focus on specific aspects, characteristics, or needs of objects, systems, or processes. These inspections require specialized knowledge, skills, or tools to assess unique or complex features, often beyond the scope of routine inspections. Specialized inspections may be conducted by experts or specialists in specific fields, addressing specific requirements, regulations, or industry standards. Examples of specialized inspections include audits for compliance with environmental regulations, inspections of critical infrastructure, or examinations of highly technical or specialized equipment.

The choice and frequency of inspections depend on various factors, including the type of object or system being inspected, its criticality or complexity, regulatory requirements, and organizational objectives. Effective inspections contribute to the overall maintenance, reliability, and safety of objects, processes, or systems.

Inspection in Various Industries

Construction and Engineering

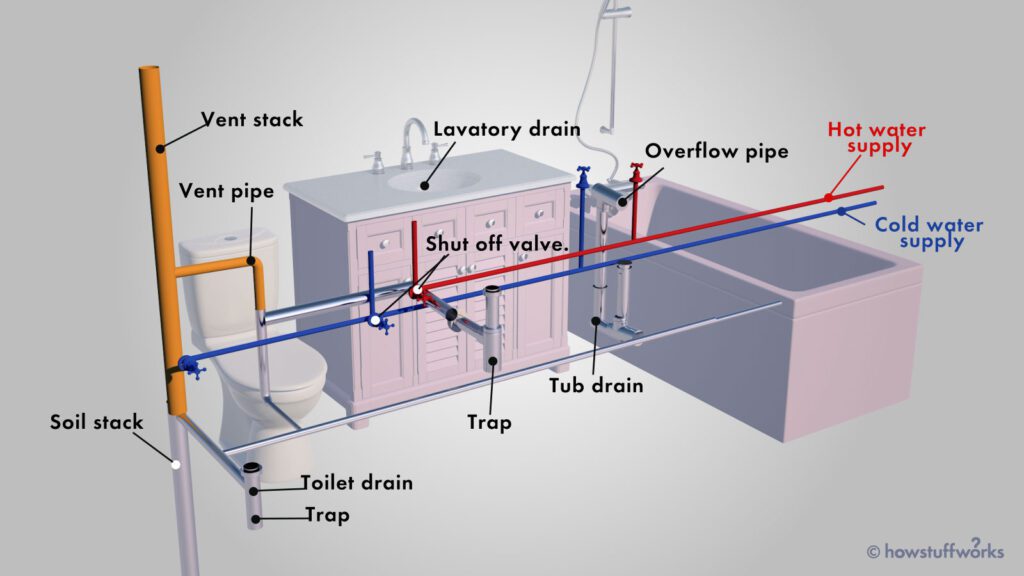

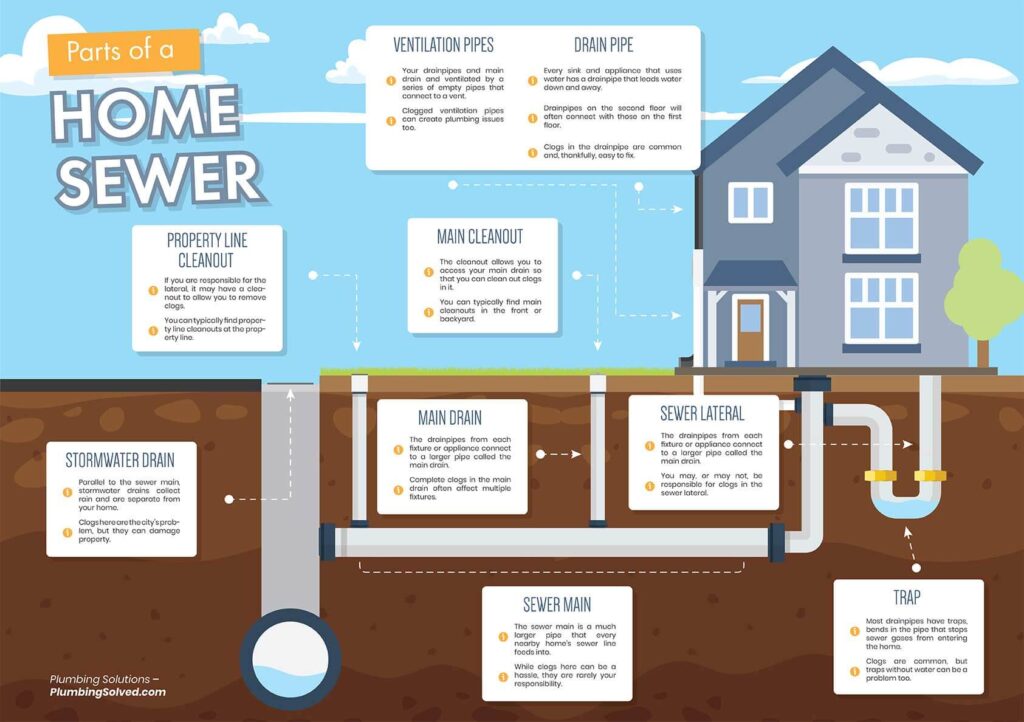

Inspections play a pivotal role in the construction and engineering sector to ensure compliance with building codes, safety regulations, and quality standards. Construction inspections involve assessing foundation integrity, structural components, electrical systems, ventilation, or fire safety measures. Engineering inspections cover areas such as infrastructure projects, bridges, roads, or manufacturing facilities. These inspections help identify any deviations or defects, ensuring that projects meet safety and quality requirements, minimizing risks, and protecting public welfare.

Manufacturing

In the manufacturing industry, inspections are critical for quality control, compliance verification, and operational efficiency. Inspections in manufacturing encompass product inspections, process inspections, and facility inspections. Product inspections involve assessing the quality, functionality, and conformity of finished products through visual examinations, measurement, and testing. Process inspections focus on monitoring and evaluating manufacturing processes, ensuring adherence to established standards, specifications, or safety protocols. Facility inspections involve assessing the condition and maintenance of manufacturing facilities, infrastructure, or equipment to prevent safety hazards, optimize operations, and maximize productivity.

Healthcare

Inspections in the healthcare industry are essential to maintain patient safety, regulatory compliance, and quality assurance. Healthcare inspections cover a wide range of areas, including hospitals, clinics, laboratories, pharmacies, or medical devices. Inspections focus on ensuring adherence to hygiene standards, infection control protocols, proper storage and handling of medications, compliance with privacy regulations, and equipment functionality. Regular inspections in healthcare facilities help prevent medical errors, reduce the risk of infections, maintain accreditation or licensing requirements, and safeguard the well-being of patients and healthcare professionals.

Overall, inspections play a crucial role in ensuring compliance, quality control, and risk management across various industries. By incorporating comprehensive inspection practices, organizations can proactively address issues, enhance operational efficiency, and ensure customer satisfaction and safety.