In this article, you will discover the concept of “100 percent inspection” and understand its significance in various industries. Have you ever wondered what exactly this term means? Well, get ready to uncover the ins and outs of this process as we explore how it ensures quality control, increases customer satisfaction, and ultimately leads to a more reliable end product. So, let’s embark on this enlightening journey to understand the essence of 100 percent inspection.

What Is 100 Percent Inspection?

Definition of 100 percent inspection

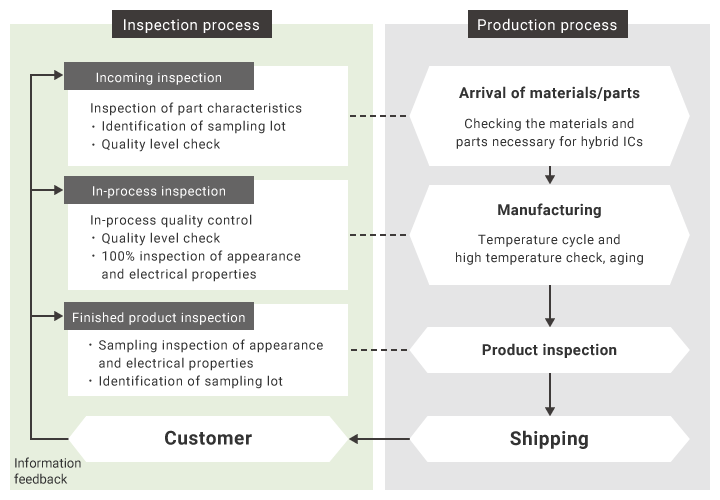

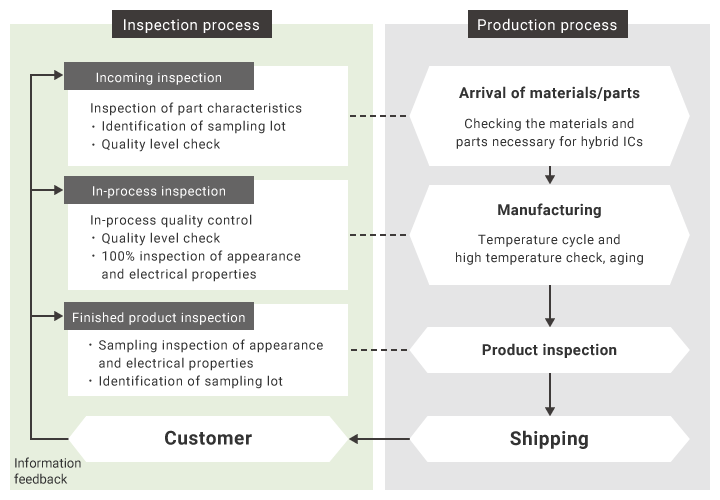

100 percent inspection, also known as full inspection or complete inspection, is a quality control method in which every single unit or item of a product is thoroughly examined to ensure its compliance with specified standards, requirements, or specifications. Unlike sampling inspection, where only a small portion of the products are inspected, 100 percent inspection leaves no room for error as each and every item is meticulously scrutinized.

Importance of 100 percent inspection

The importance of 100 percent inspection cannot be overstated, especially in industries where product quality and safety are of utmost priority. By inspecting each individual unit, companies can significantly reduce the risk of defective products reaching the market, which can lead to customer dissatisfaction, expensive recalls, damaged reputation, and potential legal issues. Ensuring the highest level of quality through 100 percent inspection inspires customer confidence and establishes a strong brand image in the market.

Types of products that require 100 percent inspection

While 100 percent inspection can be beneficial for various industries, some products necessitate this level of scrutiny more than others. Highly regulated industries such as pharmaceuticals, medical devices, aerospace, automotive, and food and beverage often require 100 percent inspection due to the critical nature of their products. In these fields, the smallest defect or deviation can have severe consequences, making it essential to examine every unit to maintain quality and safety standards.

Benefits of 100 percent inspection

Implementing 100 percent inspection offers numerous benefits for both businesses and consumers alike. Firstly, by inspecting every item, companies can ensure consistent quality, leading to higher customer satisfaction and loyalty. Additionally, it reduces the risk of product recalls, which are not only costly but also damage a company’s reputation. High-quality products resulting from 100 percent inspection also reduce waste and the need for rework, making the manufacturing process more efficient and cost-effective in the long run. Moreover, it helps identify and address potential issues early on, preventing defects from reaching the market and potentially causing harm to end-users.

Limitations of 100 percent inspection

Despite its undeniable advantages, 100 percent inspection does have certain limitations. One major limitation is the higher cost associated with inspecting each and every unit. The labor and time required for thorough inspection can significantly increase production costs, particularly for large-scale manufacturing operations. Additionally, 100 percent inspection may not be feasible or practical for certain products due to their size, complexity, or production volume. In such cases, a well-designed sampling inspection plan may be more appropriate, striking a balance between cost and quality control.

Comparison with sampling inspection

Sampling inspection involves selecting a representative sample from a batch or lot of products and inspecting them as per an established sampling plan. Unlike 100 percent inspection, sampling inspection relies on statistical analysis to infer the quality of the entire batch based on the results of the sample. While sampling inspection is more cost-effective and efficient in terms of time and resources, it carries a certain level of risk as defects may go unnoticed if they occur in non-inspected units. On the other hand, 100 percent inspection provides a higher degree of certainty by examining each and every unit, guaranteeing a lower risk of defective products reaching the market.

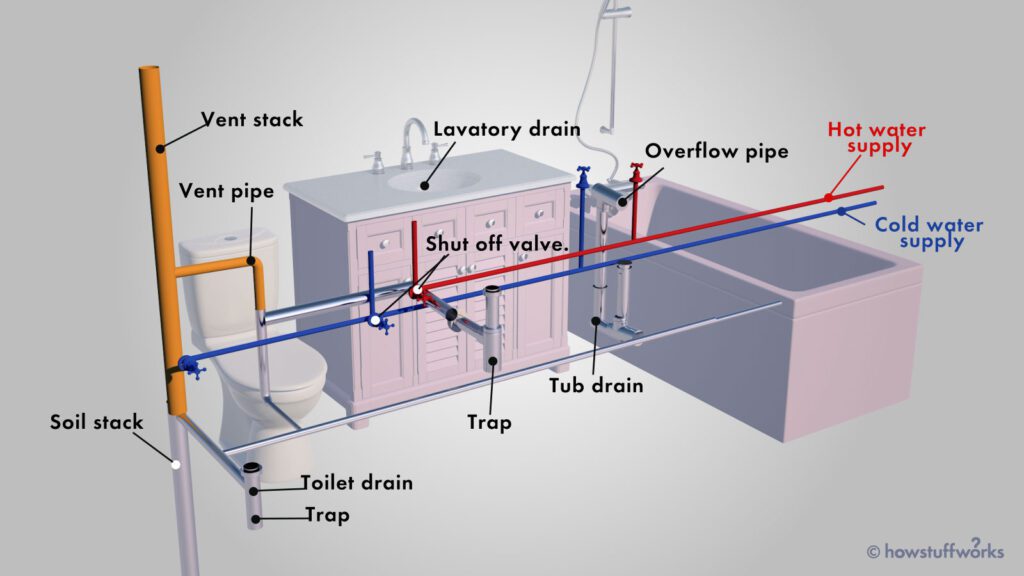

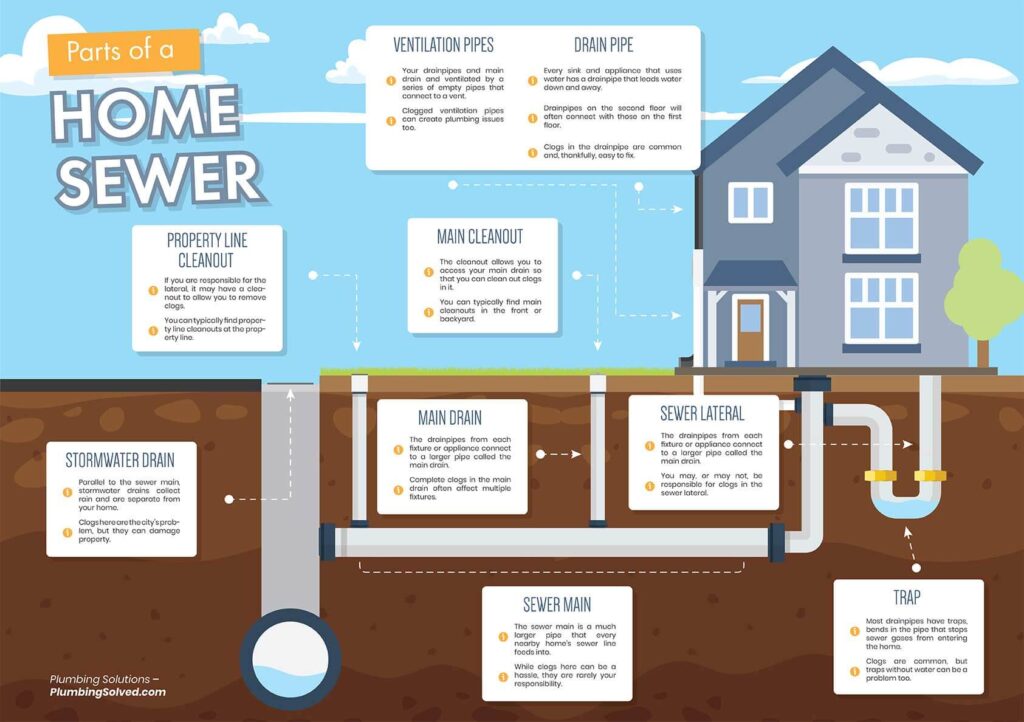

Methods and techniques used in 100 percent inspection

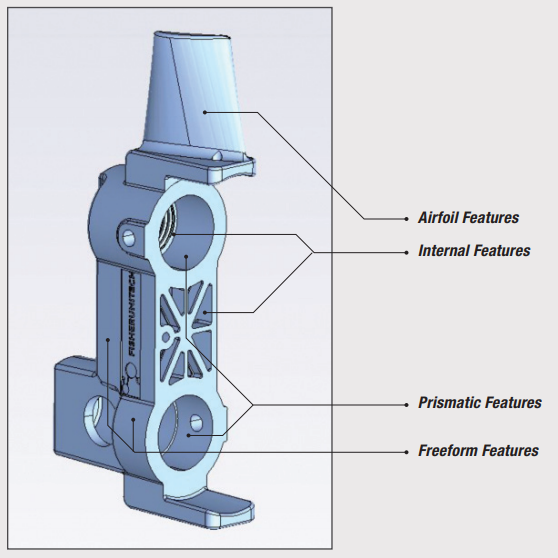

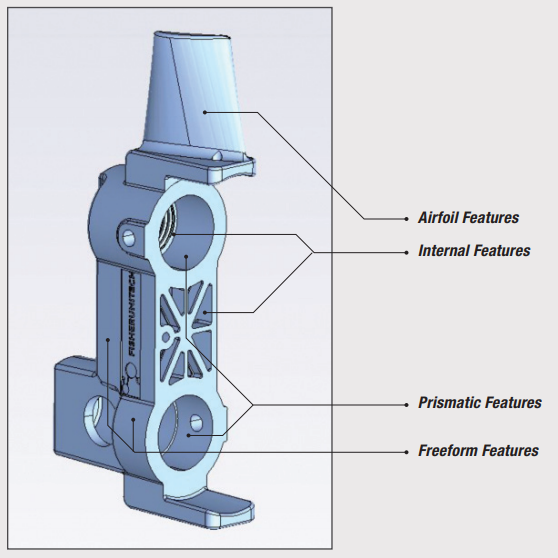

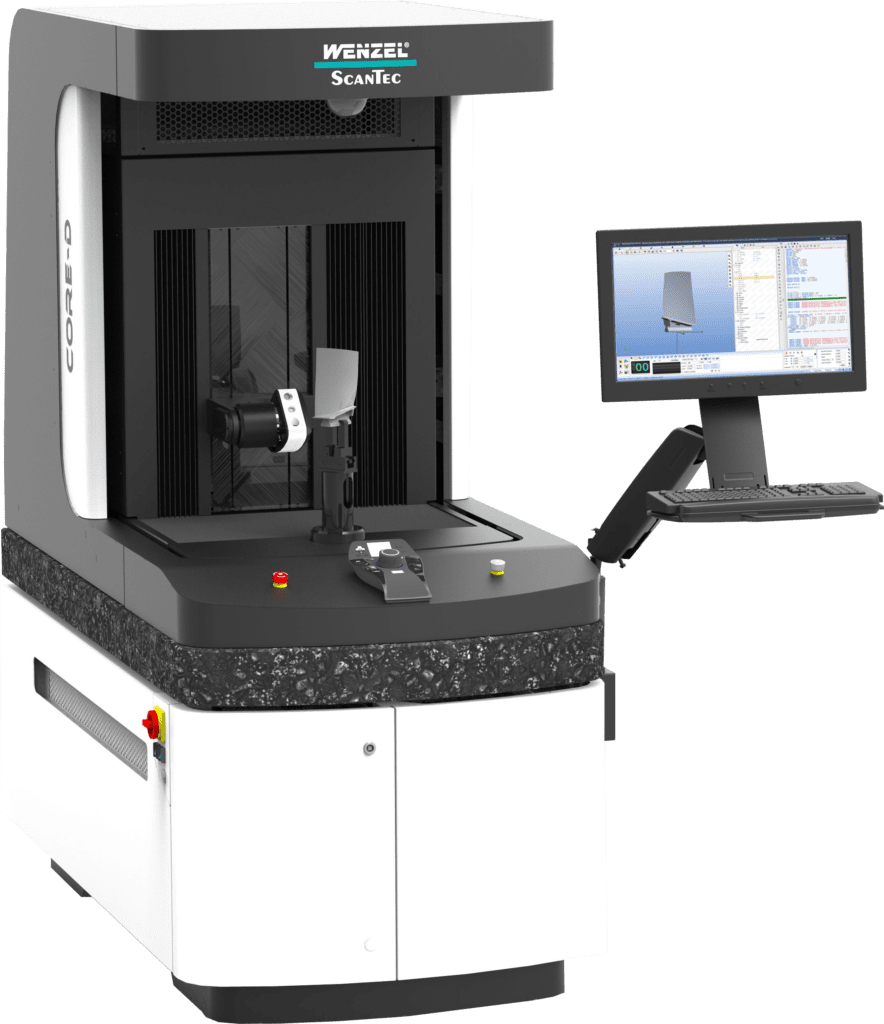

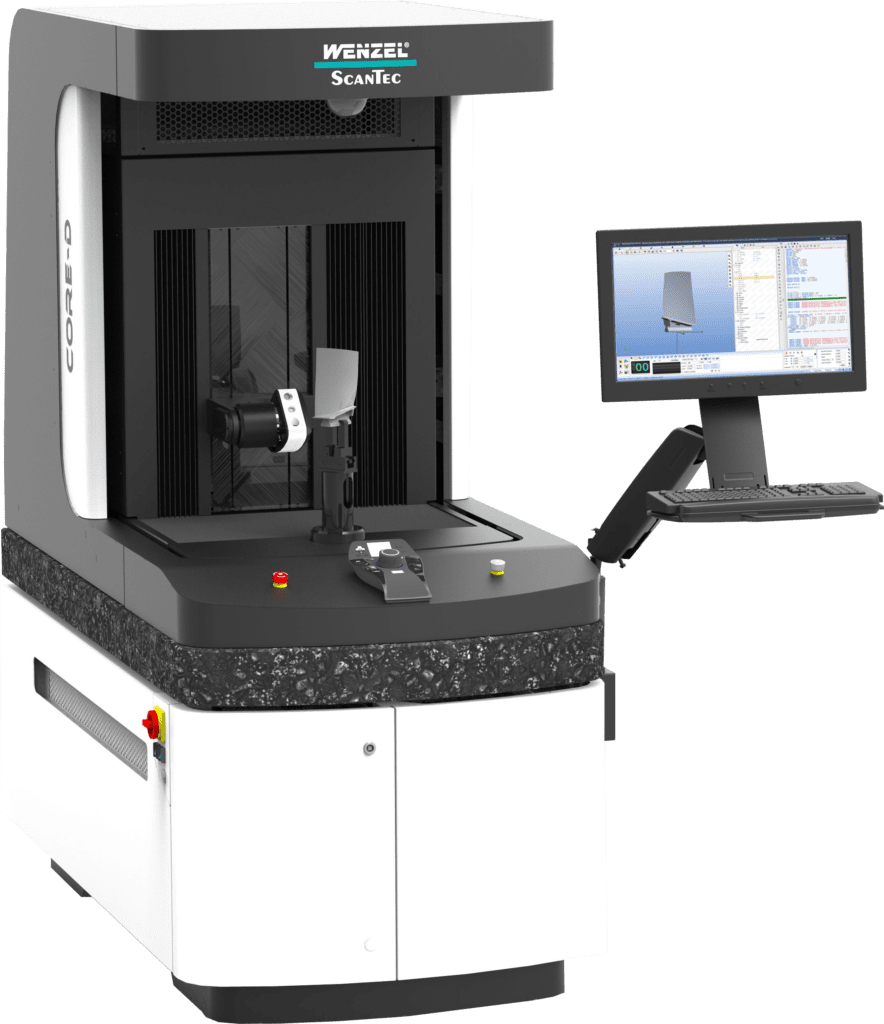

Various methods and techniques are employed in 100 percent inspection to facilitate thorough examination and ensure product quality. Visual inspection is commonly used to detect surface defects, irregularities, or discrepancies in appearance. Measurements with precision instruments are performed to verify dimensional accuracy and tolerances. Other techniques, such as X-ray or ultrasonic testing, may be utilized to detect internal flaws or hidden defects. In some cases, functional testing or performance evaluation may be necessary, especially for products that involve electrical or mechanical components.

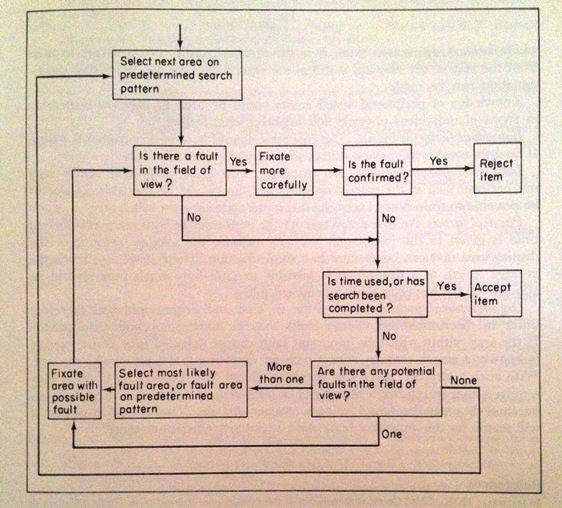

Automated vs manual 100 percent inspection

100 percent inspection can be conducted either through automated or manual means, each with its own advantages and considerations. Automated inspection systems employ advanced technologies such as machine vision, artificial intelligence, and robotics to rapidly and accurately examine products. These systems can detect defects with high precision, classify them, and even provide real-time feedback for process improvement. Manual inspection, on the other hand, relies on trained personnel to visually inspect, measure, and evaluate each unit. While automation offers speed and consistency, manual inspection allows for greater flexibility in handling diverse products and adapting to rapidly changing requirements.

Challenges in implementing 100 percent inspection

Implementing 100 percent inspection can pose several challenges for businesses. The most significant challenge is the cost associated with the time and resources required to inspect each unit. For some industries, this cost may be justified due to the critical nature of the products, but for others, finding a balance between quality control and production efficiency becomes paramount. Another challenge is ensuring accuracy and repeatability, especially in cases where human interpretation is involved. Calibration, training, and maintaining standardized inspection protocols are necessary to minimize errors and inconsistencies. Furthermore, integrating 100 percent inspection seamlessly into the production line without causing delays or disruptions requires careful planning and coordination.

Case studies on successful implementation of 100 percent inspection

Several case studies provide valuable insights into the successful implementation of 100 percent inspection across different industries. In the automotive sector, a leading manufacturer adopted 100 percent inspection for critical components such as airbags and braking systems. By doing so, they drastically reduced failure rates, ensuring the highest levels of safety for their customers. In the pharmaceutical industry, a company implemented 100 percent inspection of medicine packaging to prevent counterfeit products from entering the market. This not only safeguarded patient health but also protected the company’s brand integrity. These case studies demonstrate the positive impact of 100 percent inspection on product quality, customer satisfaction, and overall business success.

In conclusion, 100 percent inspection is a comprehensive quality control method that involves thoroughly examining each and every unit of a product to ensure its compliance with specified standards. While it may come at a higher cost compared to sampling inspection, 100 percent inspection offers numerous benefits in terms of consistent quality, reduced risk of defects, and enhanced customer confidence. However, it is essential to consider the limitations and challenges associated with its implementation and choose the most appropriate inspection method based on the nature of the product, production volume, and industry requirements. Ultimately, 100 percent inspection plays a crucial role in maintaining and improving product quality, safety, and customer satisfaction across various industries.