In today’s rapidly evolving world of software development, the question often arises: why do we favor inspection over testing? The answer lies in the fact that while testing serves its purpose in finding errors and bugs, inspection goes a step further by preventing them from occurring in the first place. By thoroughly examining the code, design, and documentation, inspection allows us to catch potential issues early on, leading to more efficient and error-free software development. So, let’s explore why inspection is truly the superior approach when it comes to ensuring the quality and reliability of our digital creations.

The Importance of Inspection

Definition of Inspection

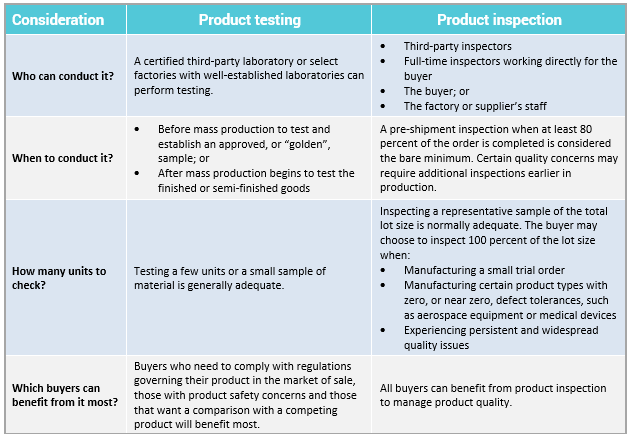

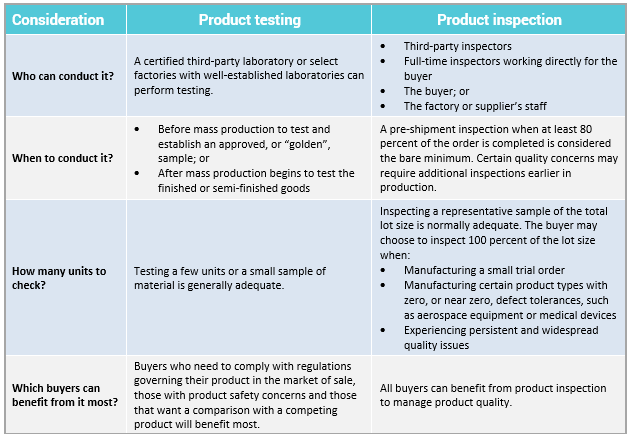

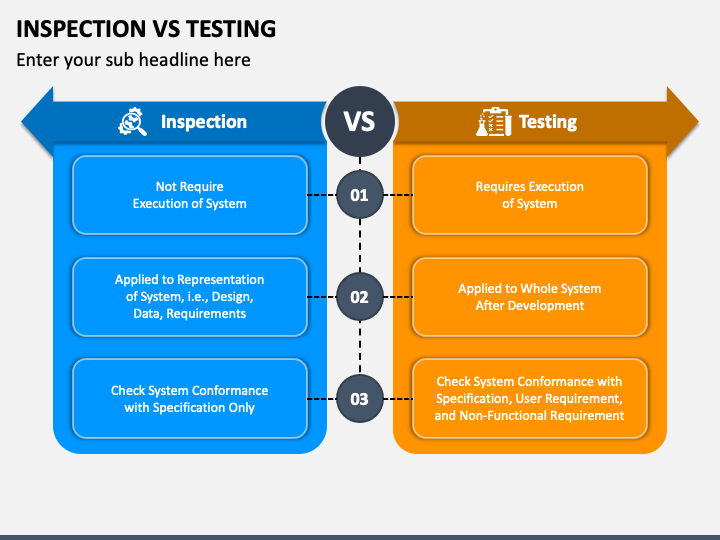

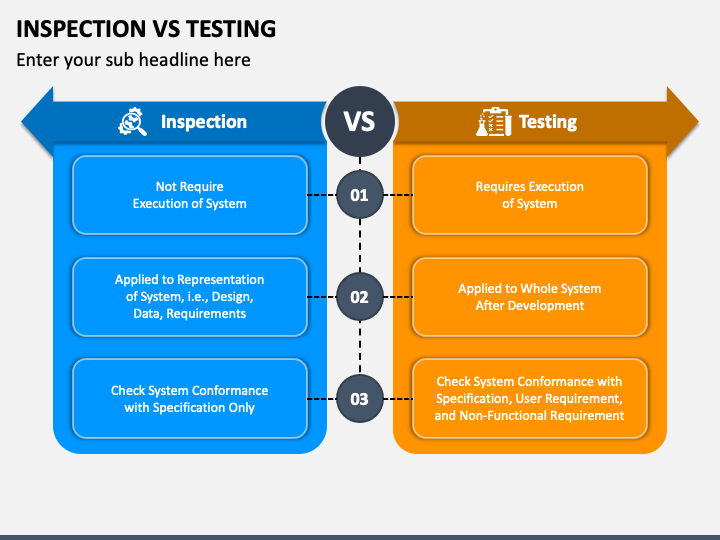

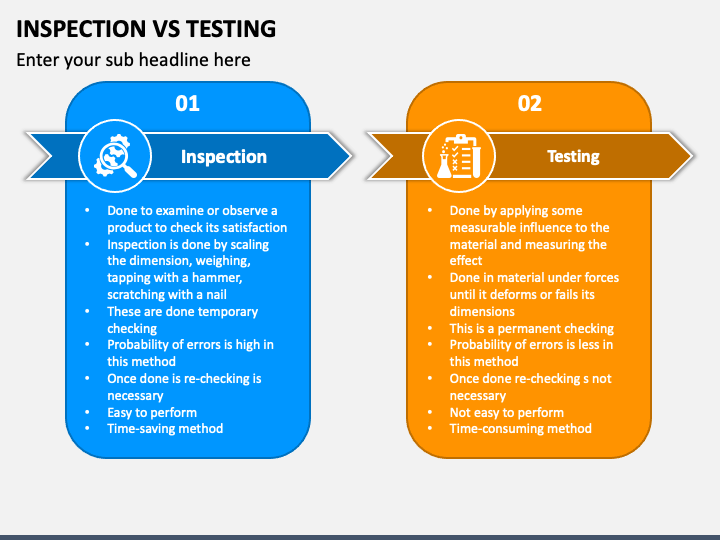

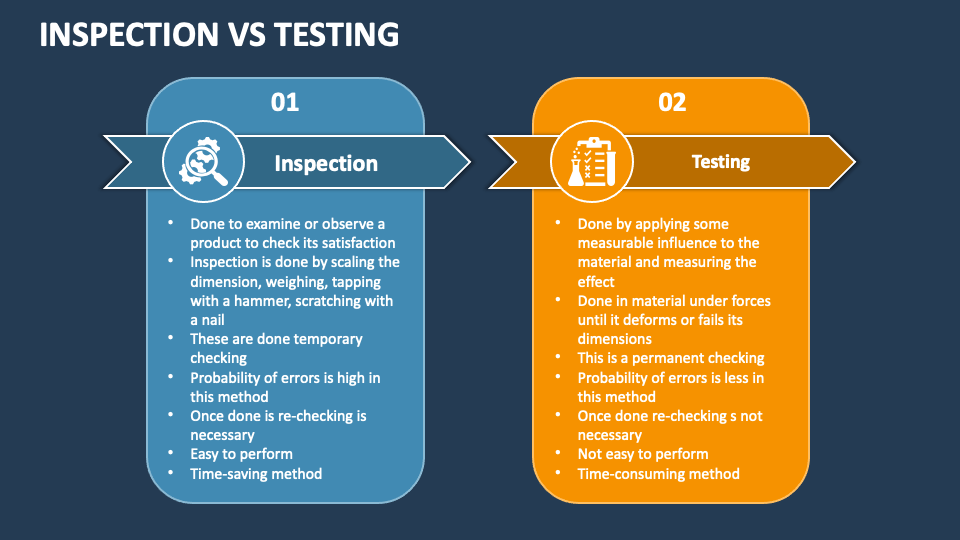

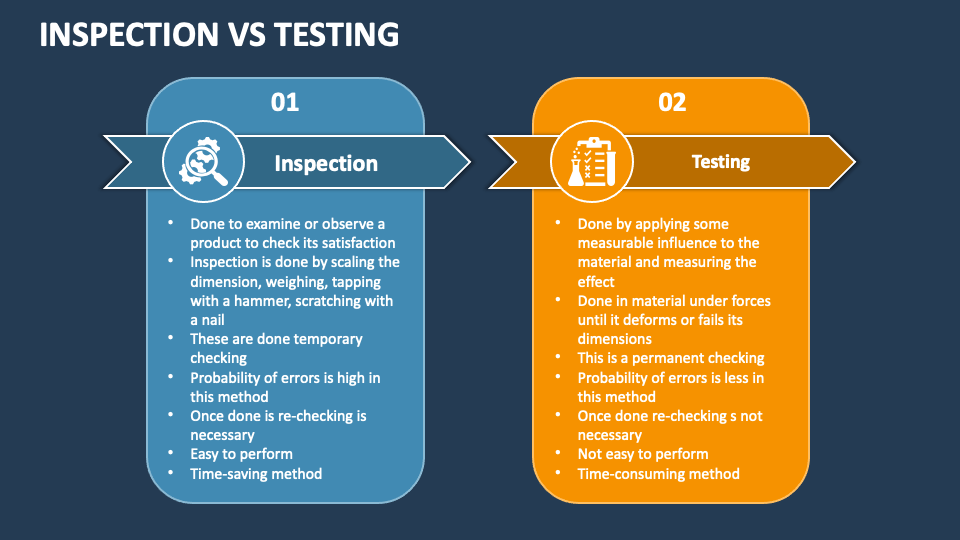

Inspection is the systematic examination and evaluation of an object, system, or process to determine its compliance with predefined standards or specifications. It involves scrutinizing various aspects, such as design, functionality, and performance, to identify potential issues or areas of improvement.

Understanding the Purpose

The primary purpose of inspection is to ensure quality control and assurance. By thoroughly examining a product or system, inspection aims to identify any deviations from the desired specifications or requirements. It helps prevent defects, improve efficiency, and enhance customer satisfaction. Inspection plays a crucial role in various industries, including manufacturing, software development, construction, and healthcare.

Benefits of Inspection

Inspection offers numerous benefits that contribute to the overall success and quality of a product or system. It helps in:

-

Enhancing Quality: Through detailed examination, inspection helps identify and rectify deficiencies, resulting in a higher quality end product.

-

Ensuring Compliance: Inspection ensures that the product or system adheres to the required standards, regulations, and specifications.

-

Improving Efficiency: By identifying bottlenecks and areas of improvement, inspection allows for streamlining processes and enhancing overall efficiency.

-

Reducing Costs: Timely identification and resolution of issues during inspection help in minimizing rework costs and avoiding potential failures.

-

Building Trust: Inspection instills confidence in the stakeholders, assuring them that the product or system meets the necessary criteria.

-

Preventing Recurrence: By addressing issues at the root cause, inspection helps prevent the recurrence of similar problems in the future.

Limitations of Testing

Definition of Testing

Testing refers to the process of evaluating a product or system’s performance, functionality, and compatibility by executing its components or functions under controlled conditions. It involves conducting experiments, running simulations, and analyzing results to assess the system’s behavior.

Inherent Challenges

While testing is an essential part of ensuring quality, it does have some limitations. These challenges include:

-

Incomplete Coverage: It is often difficult to test every possible scenario and combination, leading to potential blind spots and untested areas.

-

Time Constraints: Testing requires significant time and effort, leading to tight schedules and limited test coverage.

-

Costly Endeavor: Comprehensive testing may involve significant resources, such as labor, tools, and equipment, resulting in higher costs.

-

Unrealistic Assumptions: Test environments may not accurately mimic real-world conditions, leading to unrealistic results and inaccurate conclusions.

Drawbacks of Testing

Although testing is crucial, it has its drawbacks, such as:

-

Late Detection of Issues: Testing typically occurs after the product or system has been developed, making it difficult to address and rectify issues at an early stage.

-

Reliance on Sampled Data: Testing often relies on a subset of data, which may not fully represent the entire population or usage scenarios, leading to potential bias.

-

Limited Scope for Human Expertise: Testing is predominantly reliant on automated tools and scripts, potentially overlooking the cognitive abilities and insights of human experts.

Advantages of Inspection

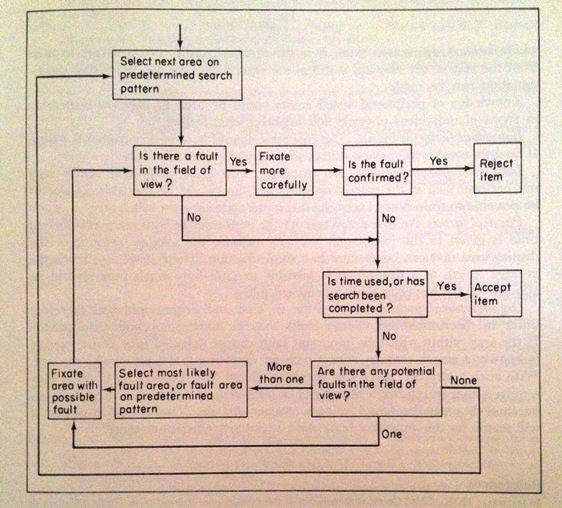

Human Expertise and Attention to Detail

One of the significant advantages of inspection over testing is its reliance on human expertise and attention to detail. Inspectors possess domain knowledge and experience that allow them to identify potential issues that may be missed by automated testing procedures. Their cognitive abilities enable them to recognize patterns, detect anomalies, and perform critical analysis, leading to more accurate and thorough evaluations.

Identification of Potential Issues

Inspection not only helps identify existing defects but also uncovers potential issues that may arise in the future. By examining the product or system in detail, inspectors can anticipate and address potential risks and vulnerabilities, thereby preventing rework, disruptions, and costly failures. This proactive approach enhances the overall quality and reliability of the product or system.

Immediate Feedback and Corrections

Unlike testing, which typically occurs after the development phase, inspection can be performed concurrently or even before the development process begins. This allows for immediate feedback and corrections, saving time, effort, and cost associated with rework or modifications. Inspection provides real-time insights and recommendations, enabling developers to make necessary adjustments promptly.

Accuracy and Precision

High Accuracy Levels

Inspection offers high levels of accuracy in evaluating the quality and compliance of a product or system. By leveraging the expertise of human inspectors, comprehensive evaluations can be performed to ensure that the desired standards and requirements are met. Inspectors pay attention to even the smallest details, reducing the chance of overlooking critical issues that automated testing may miss.

Precision in Detecting Errors

Inspection aims to detect errors and deviations precisely, ensuring that they are not overlooked or underestimated. By combining the knowledge and experience of inspectors with rigorous examination techniques, potential defects can be identified at an early stage, preventing their escalation and minimizing their impact on the overall product or system.

Eliminating False Positives and Negatives

Automated testing may sometimes generate false positives or false negatives, leading to misleading results and wasted effort. In contrast, inspection allows for careful consideration and judgment, reducing the chances of false outcomes. Human inspectors can differentiate between actual defects and potential false alarms, providing more reliable and accurate assessments.

Efficiency and Cost-Effectiveness

Optimizing Resource Utilization

Inspection offers a more resource-efficient approach compared to extensive testing. Instead of allocating substantial resources for executing diverse test cases and scenarios, inspection focuses on targeted evaluations that are tailored to the specific needs and requirements. This optimization of resources ensures a more efficient utilization of time, effort, and cost.

Reduced Time and Effort

While testing may require significant time and effort to cover various test cases and iterations, inspection can provide quicker feedback and evaluations. By leveraging human expertise and attention to detail, inspection can expedite the identification and rectification of issues, streamlining the development process and reducing the overall time and effort invested.

Minimizing Overall Costs

Inspecting a product or system early and regularly helps minimize the overall costs associated with defects and failures. By identifying and addressing issues promptly, inspection prevents the proliferation of errors, minimizing the extent of rework, repairs, or even potential legal implications. The cost-saving benefits of inspection make it a more cost-effective approach in the long run.

Comprehensive Coverage

Thorough Examination of Entire System

Inspection offers a comprehensive evaluation that examines various facets of a product or system. Unlike testing, which may focus on specific functionalities or scenarios, inspection considers the holistic view to ensure that all aspects meet the desired standards. This comprehensive coverage eliminates potential blind spots and identifies any interaction issues that may arise within different components or functions.

Identifying Interaction Issues

Product or system interactions can often result in unforeseen complications or failures. Inspection addresses this by thoroughly examining the interfaces, interdependencies, and integration points between various elements. By identifying and resolving interaction issues early on, inspection promotes a more seamless and coherent operation of the final product or system.

Capturing Non-Functional Requirements

In addition to functional requirements, inspection also focuses on non-functional aspects such as performance, security, and usability. By evaluating these parameters, inspection ensures that the product or system not only functions correctly but also meets the desired level of performance, robustness, and user experience. This comprehensive approach enhances the overall quality and satisfaction of the end users.

Prevention and Early Detection

Mitigating Risks in Early Stages

Inspection allows for the identification and mitigation of risks at an early stage. By examining the product or system from its initial design phase, inspectors can assess potential vulnerabilities, design flaws, or implementation pitfalls. This proactive approach enables the development team to take preventive measures, reducing the likelihood of risks materializing into significant issues later on.

Preventing Escalation of Issues

When defects or issues are detected early through inspection, they can be addressed promptly, preventing their escalation into more substantial problems. Inspection provides an opportunity to rectify deficiencies before they impact other components or functionalities, minimizing the ripple effect of defects and improving overall system stability.

Reducing Impact of Defects

Defects often have wide-ranging consequences, causing disruptions, delays, or even system failures. Inspection helps reduce the impact of defects by identifying and resolving them at an early stage. By proactively addressing potential issues, inspection minimizes the likelihood of defects propagating throughout the system, ensuring smoother operations and higher levels of customer satisfaction.

Flexibility and Adaptability

Multiple Inspection Techniques

Inspection offers flexibility by utilizing various techniques tailored to the specific needs and context. Depending on the nature of the product or system, different inspection methods can be employed, such as code reviews, walkthroughs, or formal inspections. This adaptability allows for customization and ensures that the most suitable approach is adopted for comprehensive evaluations.

Adapting to Various Environments

Inspection can be adapted to different environments, including regulated industries, safety-critical systems, or agile software development. The versatility of inspection enables it to be seamlessly integrated into diverse settings, ensuring that quality control and assurance are maintained across various domains and projects.

Ease of Incorporating Changes

As the development process progresses, changes and modifications may be required. Inspection offers the advantage of flexibility in accommodating these changes. Unlike testing, which may require significant retesting efforts, inspection can adapt to incorporate alterations without extensive overhead, allowing for a more efficient and agile development process.

Knowledge Sharing and Learning

Collaboration and Communication

Inspection fosters collaboration and communication among team members. During the inspection process, different stakeholders, including developers, testers, and subject matter experts, come together to critically evaluate the product or system. This collaborative environment allows for knowledge sharing, brainstorming, and constructive discussions, leading to enhanced understanding, alignment, and team cohesion.

Opportunity for Skill Enhancement

Through inspection, team members are exposed to different perspectives, approaches, and best practices. This exposure provides an opportunity for skill enhancement, enabling individuals to broaden their knowledge, refine their expertise, and acquire new techniques. Inspection promotes continuous learning, contributing to the professional growth and development of team members.

Promoting Collective Learning

Inspection not only facilitates individual skill enhancement but also promotes collective learning within the team or organization. Lessons learned during inspections can be documented, shared, and utilized in future projects. By leveraging shared knowledge and experiences, inspection enables the accumulation of organizational wisdom, leading to improved practices, better decision-making, and ultimately, higher quality outcomes.

Conclusion

Emphasizing the Importance of Inspection

Inspection plays a crucial role in ensuring the quality, reliability, and compliance of products and systems. Its reliance on human expertise, attention to detail, and proactive evaluation distinguish it from testing. Inspection offers several advantages, including accuracy, precision, efficiency, comprehensive coverage, prevention, adaptability, and knowledge sharing.

Balancing with Appropriate Testing

While inspection offers numerous benefits, it is essential to recognize that testing also has its significance in quality control and assurance. Inspection and testing should be seen as complementary approaches, with each fulfilling distinct purposes and addressing specific aspects of evaluation. Finding the right balance between inspection and testing is key to maximizing the effectiveness and efficiency of quality assurance practices.

Adopting a Holistic Approach

To achieve optimal results, organizations should adopt a holistic approach that integrates both inspection and testing into their quality assurance processes. By leveraging the advantages of inspection and testing, organizations can enhance the overall quality, reliability, and customer satisfaction of their products and systems. A comprehensive and well-rounded approach to quality assurance ensures that all aspects of evaluation are adequately addressed, resulting in better outcomes and long-term success.