Are you curious about the durability of Flex Seal on your roof? Wondering if it’s a reliable solution for your roofing needs? In this article, we’ll explore the longevity of Flex Seal and address the question on the minds of many homeowners: How long will Flex Seal last on my roof? Whether you’re dealing with leaks, cracks, or other roofing issues, we’ll provide you with insights to help you make an informed decision about using Flex Seal as a potential solution.

Factors Affecting the Longevity of Flex Seal on Roofs

When it comes to the longevity of Flex Seal on roofs, there are several factors that can affect its effectiveness and durability. By understanding these factors, you can make informed decisions about the application and maintenance of Flex Seal on your roof.

Quality of Application

The quality of the application plays a significant role in determining how long Flex Seal will last on your roof. It is important to follow the manufacturer’s instructions carefully and ensure that the sealant is applied evenly and thoroughly. Any gaps or uneven application can compromise the effectiveness of the seal and lead to premature deterioration.

Type of Roofing Material

Different roofing materials have varying levels of compatibility with Flex Seal. Some materials, such as metal roofs and rubber roofs, tend to work exceptionally well with the sealant. On the other hand, certain materials like clay tiles and slate roofs may not provide an ideal surface for Flex Seal. It is essential to consider the compatibility of your roofing material with the product before applying.

Climate and Weather Conditions

The climate and weather conditions in your area can have a significant impact on the longevity of Flex Seal. Extreme temperatures, excessive rainfall, hailstorms, snow, ice, and high winds can all test the durability of the sealant. In regions with harsh weather conditions, it may be necessary to apply additional layers of Flex Seal or consider alternative roofing solutions.

Exposure to UV Rays

UV rays from the sun can cause degradation of the Flex Seal over time. Prolonged exposure to sunlight can lead to fading and reduced effectiveness of the sealant. Protecting the seal by applying additional layers or using UV-resistant coatings can help prolong its lifespan.

Roof Surface Preparation

Proper roof surface preparation is crucial for the longevity of Flex Seal. Before applying the sealant, it is important to clean and remove any debris from the roof surface. Repairing damaged areas, eliminating ponding water, and smoothing out rough surfaces can ensure a smooth and even application of the sealant.

Existing Roof Damage

Flex Seal is known for its effectiveness in sealing small leaks. However, its ability to repair larger damages may vary depending on the severity and type of roof damage. It is important to assess the extent of the damage and consult with a professional to determine the best course of action for addressing larger issues.

Maintenance and Upkeep

Regular maintenance and upkeep are key to prolonging the lifespan of Flex Seal on your roof. Regular inspections can help identify any potential issues or areas that may require reapplication. Periodic reapplication of the sealant, cleaning and removing stains, and addressing any structural issues can help ensure the long-lasting performance of Flex Seal.

Application Technique

The technique used during the application of Flex Seal can significantly impact its longevity. Consistency in the application, proper coverage and overlapping, and ensuring a tight seal on joints and cracks are crucial for long-lasting results. Care should be taken to avoid the formation of air bubbles, as they can compromise the effectiveness of the seal.

Frequency of Roof Traffic

The frequency of roof traffic can also affect the lifespan of Flex Seal. If your roof is regularly accessed for maintenance or other purposes, the constant foot traffic can cause wear and tear on the sealant. Taking precautions to minimize traffic and providing protective measures, such as walkways or mats, can help extend the effectiveness of the seal.

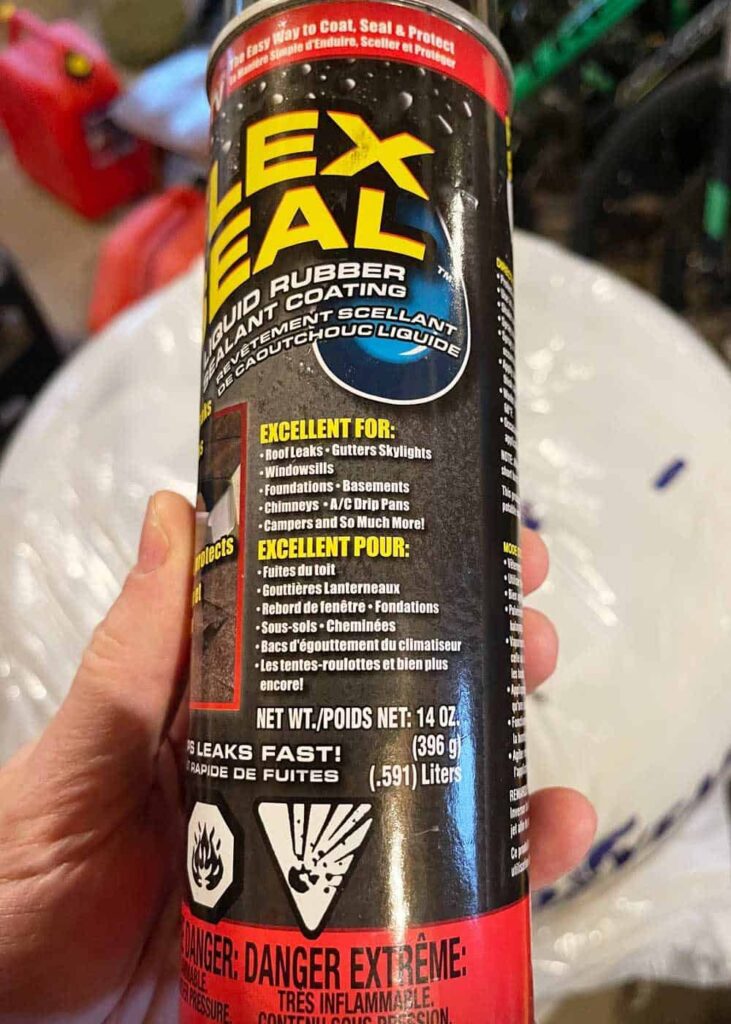

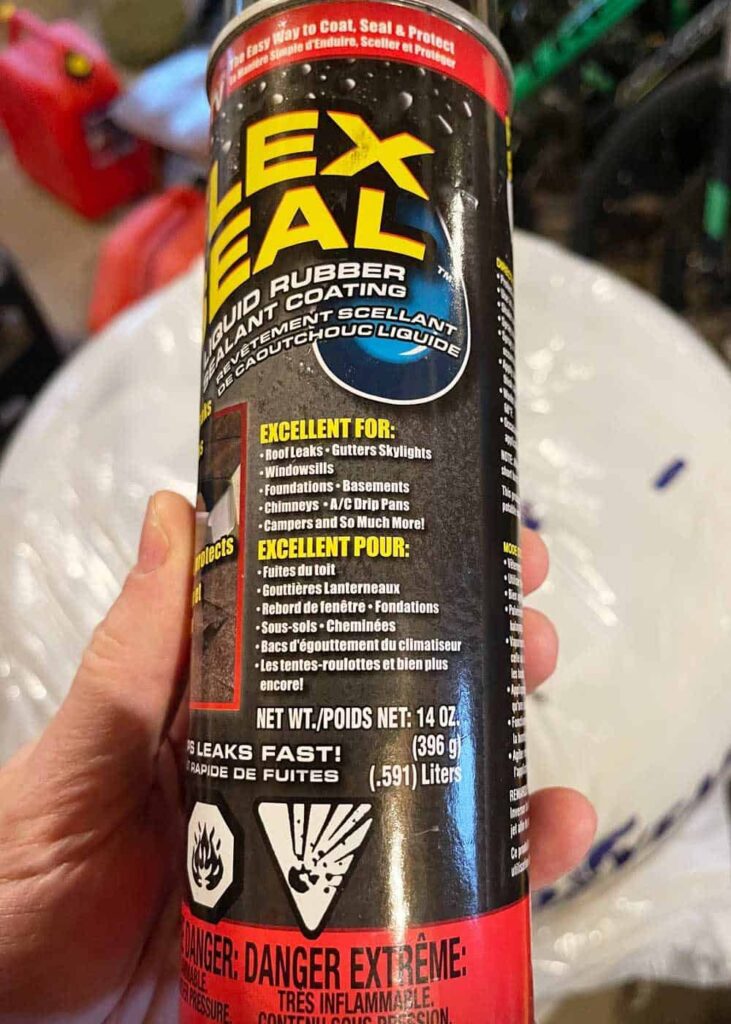

Flex Seal Product Used

Different Flex Seal products offer varying levels of durability and longevity. Products such as Flex Seal Aerosol Spray, Flex Seal Liquid, Flex Seal Clear, Flex Seal Colors, Flex Seal Flex Shot, Flex Seal Flex Tape, Flex Seal Flex Glue, Flex Seal Putty, Flex Seal Rubber Adhesive, and Flex Seal Rust-Oleum LeakSeal provide different features and benefits. It is important to choose the right product for your specific roofing needs to ensure optimal performance and longevity.

Efficiency of Application

To maximize the longevity of Flex Seal on your roof, it is important to ensure the efficiency of the application process. Several factors can influence the efficiency of application and contribute to the overall durability of the seal.

Proper Surface Cleaning

Before applying Flex Seal, it is crucial to clean the roof surface thoroughly. Removing any dirt, debris, or loose particles ensures better adhesion and reduces the risk of premature failure. Use a broom or a pressure washer to clean the surface and allow it to dry completely before applying the sealant.

Application Method

The method used for applying Flex Seal can impact its efficiency. Whether you choose to use a brush, roller, or spray can, it is important to follow the manufacturer’s instructions and ensure even coverage of the sealant. Each method may have specific instructions and guidelines for achieving optimal results.

Number of Coats

Applying multiple coats of Flex Seal can enhance its durability and increase its resistance to external factors. Depending on the severity of the surface damage or the desired level of protection, it may be necessary to apply multiple coats of the sealant. Follow the recommended number of coats specified by the manufacturer for maximum effectiveness.

Curing Time

Curing time refers to the time required for the Flex Seal to dry and fully bond with the roof surface. It is important to allow adequate curing time as specified by the manufacturer before exposing the roof to water, UV rays, or other external factors. Rushing the curing process can compromise the effectiveness of the sealant and lead to premature failure.

Sealant Thickness

The thickness of the Flex Seal application can impact its efficiency and longevity. Applying the sealant too thin may result in weak coverage and potential gaps, while applying it too thick may lead to slower drying time and potential cracking. Follow the manufacturer’s guidelines on the recommended thickness to achieve optimal results.

Types of Roofing Materials

The type of roofing material you have can influence the effectiveness and longevity of Flex Seal on your roof. Understanding the characteristics of different roofing materials can help you determine the compatibility and suitability of Flex Seal for your specific roof.

Metal Roofs

Flex Seal is known to work exceptionally well on metal roofs. Its ability to adhere to metal surfaces and withstand extreme temperatures makes it an ideal choice for sealing metal roof leaks. The flexibility of the sealant allows it to expand and contract with the metal roof, ensuring long-lasting protection.

Asphalt Shingles

Flex Seal can be used on asphalt shingle roofs to repair small leaks or cracks. However, the rough texture of asphalt shingles may make it challenging to achieve a smooth and even application. It is important to prepare the surface properly and ensure thorough coverage to maximize the effectiveness of the sealant.

Wooden Shingles/Shakes

While Flex Seal can be applied to wooden shingles or shakes, its longevity may vary. Wood is a porous material, and the sealant may penetrate the surface or be absorbed over time, reducing its effectiveness. Regular inspections and periodic reapplication may be necessary to maintain the seal.

Rubber Roofs

Flex Seal is compatible with rubber roofs and can provide effective protection against leaks and cracks. The elastomeric properties of the sealant allow it to expand and contract with the rubber roof, ensuring a tight and durable seal. Proper surface preparation and thorough application are essential for optimal performance.

Concrete Tiles

Flex Seal can be used on concrete tile roofs to seal minor leaks or cracks. The smooth surface of concrete tiles allows for easy application and good adhesion. However, it is important to consider the condition of the tiles and any underlying structural issues before applying the sealant.

Clay Tiles

Clay tiles may not provide an ideal surface for Flex Seal. The uneven texture and porous nature of clay tiles may make it difficult for the sealant to adhere effectively. It is recommended to consult with a professional to determine the best repair and sealing options for clay tile roofs.

Slate Roofs

Flex Seal is not recommended for use on slate roofs. The natural properties of slate, such as its smoothness and non-porous surface, may prevent the sealant from adhering properly. Alternative solutions should be considered for sealing leaks or cracks on slate roofs.

Climate and Weather Conditions

The climate and weather conditions in your area can significantly impact the effectiveness and longevity of Flex Seal on your roof. Understanding how different weather elements can affect the seal can help you make informed decisions about the application and maintenance of Flex Seal.

Extremes in Temperature

Extreme temperature fluctuations can test the durability of Flex Seal. Constant exposure to high heat or freezing temperatures can cause the sealant to expand or contract, leading to potential cracking or weakening. Choosing a high-quality, weather-resistant sealant and providing additional protection against temperature extremes can help prolong its lifespan.

Excessive Rainfall

Excessive rainfall can put a strain on Flex Seal if the roof is not adequately prepared or if improper application techniques were used. Water pooling or improper drainage can cause the sealant to degrade over time. Regular inspections and proper maintenance can help identify and address any water-related issues on the roof.

Hailstorms

Hailstorms can cause significant damage to roofs, including puncturing or cracking the sealant. While Flex Seal is known for its resistance to impact, severe hailstorms may surpass its capabilities. Regular inspections after hailstorms are essential to identify any visible damage and take appropriate measures for repairs.

Snow and Ice

Snow and ice accumulation on the roof can weigh it down and potentially cause damage to the Flex Seal. The weight and pressure from the snow or ice can compromise the integrity of the sealant, leading to leaks or cracks. Proper insulation, ventilation, and snow removal measures can help minimize the impact of snow and ice on the seal.

High Winds

High winds can exert significant force on the roof, potentially causing the sealant to lift, crack, or peel. Ensure that the sealant is applied securely and has had ample curing time to bond with the roof surface. Regular inspections and timely repairs after windstorms can help maintain the effectiveness of Flex Seal.

Exposure to UV Rays

Exposure to UV rays from the sun can have a significant impact on the durability of Flex Seal. Understanding the effects of sunlight on the sealant and taking appropriate measures can help extend its lifespan.

Impact of Sunlight

Prolonged exposure to sunlight can cause the sealant to fade and deteriorate over time. UV rays can break down the sealant’s properties, leading to reduced effectiveness and potential leaks. Applying additional layers of Flex Seal or using UV-resistant coatings can provide extra protection against the damaging effects of sunlight.

Degradation of Sealant

Flex Seal is designed to be UV resistant, but extended exposure to intense sunlight can still degrade the sealant over time. Regular inspections and timely reapplication of the sealant can help maintain a strong and watertight bond, minimizing the chances of leaks or damage caused by UV degradation.

Protection through Additional Layers

To enhance the UV resistance of Flex Seal, consider applying additional layers or coatings that provide UV protection. These additional layers can act as a barrier against harmful sun rays, prolonging the lifespan of the sealant and maintaining its effectiveness.

Roof Surface Preparation

Proper roof surface preparation is essential for the long-lasting performance of Flex Seal. Taking the necessary steps to clean and prepare the roof surface ensures good adhesion and maximizes the effectiveness of the sealant.

Cleaning and Removing Debris

Before applying Flex Seal, it is important to clean the roof surface thoroughly. Remove any dirt, debris, or loose particles using a broom or a pressure washer. This step helps ensure better adhesion and prevents any foreign objects from interfering with the sealant’s performance.

Repairing Damaged Areas

Inspect the roof surface for any existing damage and repair it before applying Flex Seal. Addressing cracks, leaks, or structural issues helps create a solid foundation for the application of the sealant. Consider consulting with a professional to properly address any significant damage or structural concerns.

Eliminating Ponding Water

Proper roof drainage is crucial for the longevity of Flex Seal. Eliminate any areas of ponding water or standing water on the roof before applying the sealant. Improving the roof’s slope or installing additional drain systems can help prevent water accumulation and potential damage to the seal, enhancing its lifespan.

Smoothing Out Rough Surfaces

If the roof surface has rough areas or uneven textures, it is essential to smooth them out before applying Flex Seal. Rough surfaces can hinder proper adhesion and coverage of the sealant, leading to potential gaps or weak spots. Sanding or using appropriate roof preparation products can help create a smooth and even surface for the sealant.

Existing Roof Damage

Flex Seal is known for its effectiveness in sealing small leaks or cracks. However, its ability to address larger roof damage may vary. Understanding the capabilities of Flex Seal and its compatibility with different roof issues can help you make informed decisions about repairs and maintenance.

Effectiveness on Small Leaks

Flex Seal is widely recognized for its ability to seal small leaks or cracks on various roofing materials. Its flexibility and strong adhesion properties allow it to form a watertight seal, preventing further damage or leaks. Regular inspections and prompt application of Flex Seal on small leaks can help avoid more significant issues.

Repairing Larger Damages

While Flex Seal may temporarily address larger damages, it is important to consult with a professional to determine the best course of action. Severe roof damage, such as extensive leaks, structural issues, or sections requiring replacement, may require more comprehensive repairs and alternative solutions.

Compatibility with Different Roof Issues

Flex Seal is suitable for a wide range of roof issues, including leaks, cracks, gaps, or damaged flashing. However, understanding its compatibility with different roofing materials and specific issues is crucial. Consult with a professional to assess the condition of your roof and determine whether Flex Seal is an appropriate solution for your specific needs.

Maintenance and Upkeep

To ensure the long-lasting performance of Flex Seal on your roof, regular maintenance and upkeep are essential. By implementing a proactive approach, you can identify and address potential issues before they escalate.

Regular Inspections

Schedule regular inspections of your roof to identify any signs of damage, wear, or potential issues. Look for signs of leaks, cracking, peeling, or discoloration. Early detection allows for timely repairs and reapplication of Flex Seal, preventing further damage or deterioration.

Periodic Reapplication

Flex Seal may need periodic reapplication to maintain its effectiveness and durability. Over time, the sealant can experience wear and tear from weather elements, UV rays, and normal roof aging. Consult with a professional to determine the best interval for reapplication based on the specific conditions of your roof.

Cleaning and Removing Stains

Regularly clean your roof to remove any stains caused by dirt, debris, or organic growth. Use a gentle cleaning solution, or consult with a professional for recommendations based on your specific roofing material. Removing stains helps maintain the integrity of the sealant and enhances the overall appearance of your roof.

Addressing Roof Structural Issues

Flex Seal can provide effective sealing for leaks or minor damage, but it cannot address underlying structural issues. If you notice signs of sagging, weakened trusses, or other structural concerns, it is crucial to consult with a professional to assess and address the root cause of these issues properly.

Application Technique

Proper application technique is critical for maximizing the effectiveness and longevity of Flex Seal. Following the manufacturer’s instructions and paying attention to the details can help ensure a strong and durable seal.

Consistency of Sealant Application

Maintaining consistent application thickness and coverage throughout the entire roof surface is important for an effective seal. Follow the manufacturer’s guidelines and recommendations for the appropriate application technique, ensuring a uniform distribution of the sealant.

Coverage and Overlapping

Ensure thorough coverage of the roof surface by overlapping each application area appropriately. Properly overlapping the sealant layers helps prevent any potential gaps or weak spots that could lead to leaks or cracks. Pay close attention to areas prone to water pooling or vulnerable to extreme weather conditions.

Proper Sealing of Joints and Cracks

Focus on properly sealing joints and cracks on your roof to prevent water infiltration and further damage. Apply Flex Seal directly into the joint or crack, making sure to fill it completely. Smooth out the surface to ensure a tight and watertight bond with the sealant.

Avoiding Air Bubbles

Air bubbles can compromise the effectiveness of Flex Seal and potentially lead to premature failure. To avoid the formation of air bubbles, apply the sealant slowly and evenly, using a brush, roller, or spray can. Take your time during the application process and smooth out any bubbles that may appear.

Flex Seal Product Used

Flex Seal offers a range of products, each with its own features and benefits. Choosing the right product for your specific roofing needs can contribute to the longevity and effectiveness of the seal.

Flex Seal Aerosol Spray

Flex Seal Aerosol Spray is a versatile product that provides a convenient method for applying the sealant. It can be used on various roofing materials and offers quick and easy coverage. Follow the manufacturer’s instructions for optimal application and ensure adequate curing time.

Flex Seal Liquid

Flex Seal Liquid is a brush-on sealant that provides thick, rubberized coverage. It is ideal for larger surface areas or for repairing wider cracks and leaks. Proper surface cleaning and preparation are essential for the successful application of Flex Seal Liquid.

Flex Seal Clear

Flex Seal Clear is a transparent sealant that provides a discreet solution for sealing leaks or cracks on various roofing materials. It offers the same protection and durability as other Flex Seal products while blending seamlessly with the roof surface.

Flex Seal Colors

Flex Seal Colors are available in a range of shades to match or complement your roof color. These colored versions of Flex Seal provide the same effective sealing properties while adding a customized aesthetic appeal.

Flex Seal Flex Shot

Flex Seal Flex Shot is a thick, rubberized sealant that can be applied using a caulking gun. It is designed for precise application and provides excellent coverage for joints, cracks, or gaps. Follow the manufacturer’s instructions for proper technique and achieve optimal results.

Flex Seal Flex Tape

Flex Seal Flex Tape is a strong adhesive tape that provides quick and effective repairs for leaks or cracks. It can be used on various roofing materials and offers immediate sealing capabilities. Ensure proper surface cleaning and apply the tape according to the manufacturer’s guidelines for best results.

Flex Seal Flex Glue

Flex Seal Flex Glue is a strong, durable adhesive that provides excellent bonding capabilities. It is suitable for various roofing materials and can be used to repair or reinforce weakened areas. Proper surface preparation and application techniques are essential for optimal bonding.

Flex Seal Putty

Flex Seal Putty is a moldable sealant that provides a versatile solution for sealing leaks, cracks, gaps, or holes. It can be shaped and applied to fit the specific needs of your roof. Follow the manufacturer’s instructions for proper application and ensure a tight seal.

Flex Seal Rubber Adhesive

Flex Seal Rubber Adhesive is a specially formulated adhesive designed for bonding rubber surfaces. It provides a secure and long-lasting bond, making it ideal for repairing or reinforcing rubber roofs. Follow the manufacturer’s instructions and allow ample drying time for optimal results.

Flex Seal Rust-Oleum LeakSeal

Flex Seal Rust-Oleum LeakSeal is a multi-surface sealant that provides quick and effective sealing solutions for leaks or cracks. It can be used on various roofing materials and offers a strong and durable bond. Thoroughly clean and prepare the surface before applying LeakSeal for maximum adhesion.

In conclusion, several factors can influence the longevity of Flex Seal on roofs. Factors such as the quality of application, type of roofing material, climate and weather conditions, exposure to UV rays, roof surface preparation, existing roof damage, maintenance and upkeep, application technique, frequency of roof traffic, and the specific Flex Seal product used all play vital roles in determining the effectiveness and durability of the seal. By considering and addressing these factors, you can ensure the long-lasting performance of Flex Seal on your roof and enjoy its benefits for years to come.