In this article, you will discover the 5 fundamental inspection methods that are essential for ensuring quality and reliability in different industries. From visual inspection to magnetic particle testing, each technique plays a vital role in detecting defects and ensuring product safety. Whether you are curious about inspection methods or want to enhance your understanding of quality control, this article will provide you with a comprehensive overview of these indispensable practices. So, let’s explore the fascinating world of inspection methods together and unlock the secrets to maintaining excellence in your field.

Visual Inspection

Definition

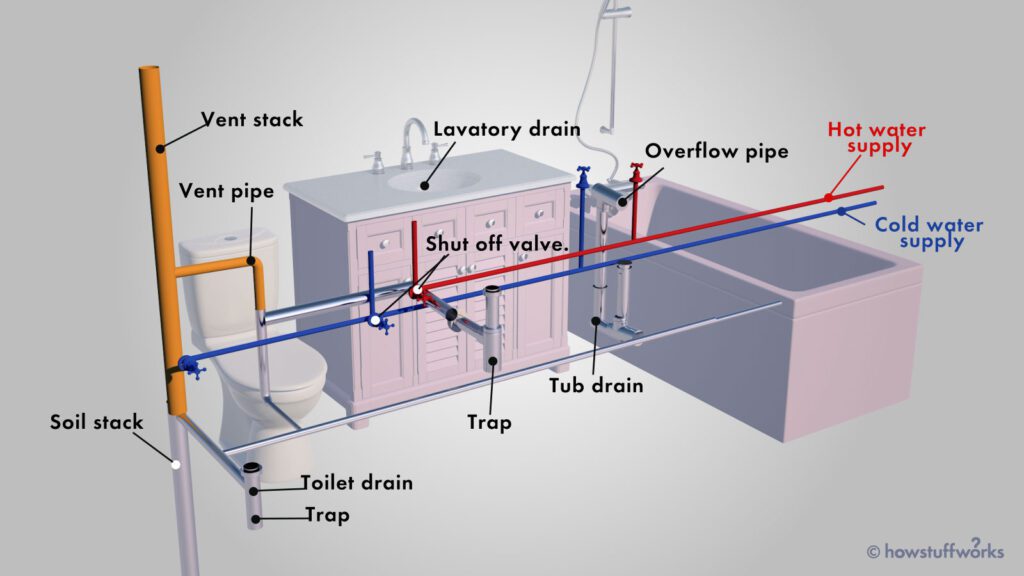

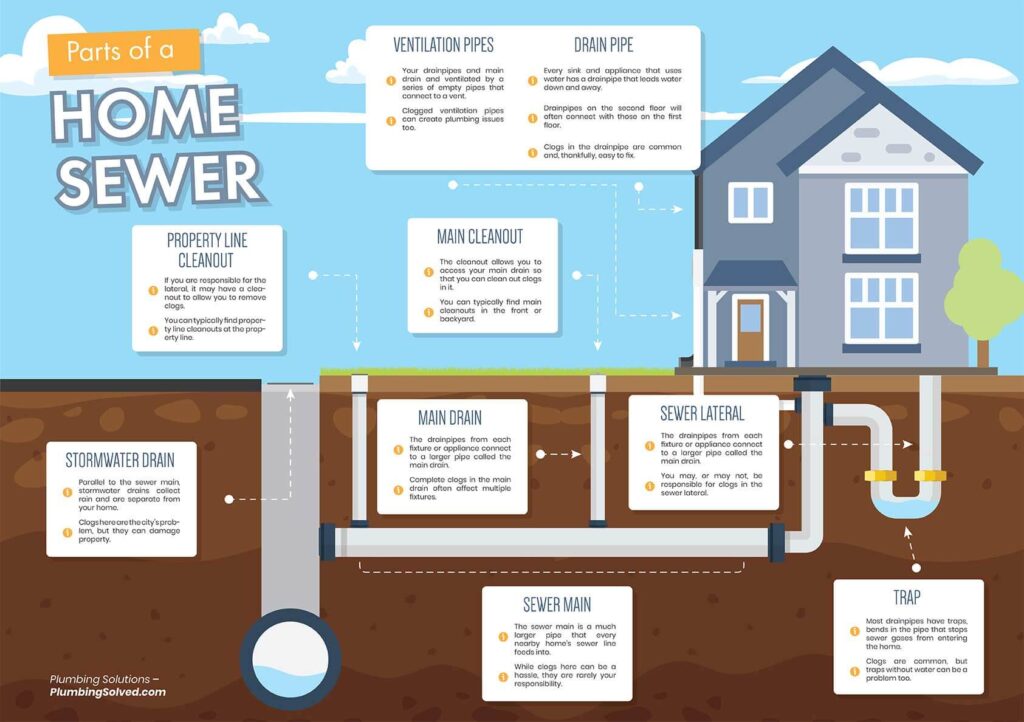

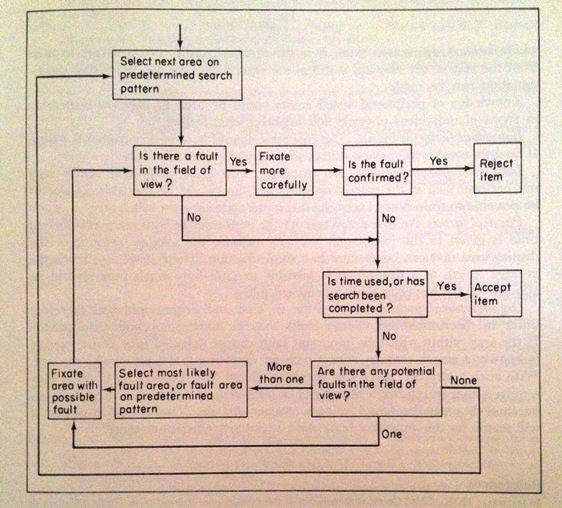

Visual inspection is a type of inspection method that relies on the use of the naked eye to examine and assess the condition, quality, and integrity of a specific object or system. It involves visually observing and evaluating various aspects such as appearance, shape, color, texture, and other visible characteristics to identify any abnormalities, defects, or irregularities.

Process

The process of visual inspection typically involves carefully examining the surface or exterior of the object or system under scrutiny. This may include looking for cracks, dents, scratches, discoloration, or any signs of damage or wear. Visual inspection can be done through direct observation or with the aid of tools such as magnifying glasses, binoculars, or cameras with high-resolution capabilities. It can be conducted in various environments, ranging from controlled laboratory settings to real-world conditions.

Advantages

Visual inspection offers several advantages. Firstly, it is a relatively simple and cost-effective method as it does not require specialized equipment or complex procedures. It can be easily performed by trained personnel or even by individuals with basic knowledge or experience. Additionally, visual inspection can provide immediate results, allowing for real-time assessment and decision-making. It is also a versatile method that can be applied to a wide range of objects or systems, including mechanical components, structures, electrical systems, and more.

Limitations

While visual inspection is a valuable method, it does have some limitations. One of the main limitations is its reliance on surface-level observations, which means that it may not detect defects or issues that are not visible to the naked eye. This makes it less effective for detecting internal or hidden flaws. Additionally, visual inspection is subjective and can be influenced by factors such as lighting conditions, human error, or individual interpretation. It is also not suitable for inspecting objects or systems in challenging environments where direct visual access is restricted, such as submerged or high-temperature areas.

Dimensional Inspection

Definition

Dimensional inspection is a type of inspection method that focuses on assessing the dimensional accuracy and precision of an object or part. It involves the measurement and comparison of physical dimensions against specified requirements or standards to determine if they adhere to the desired tolerances.

Process

The process of dimensional inspection typically involves using specialized tools and equipment to measure various dimensions such as length, width, height, diameter, thickness, or angles. Techniques used may include calipers, micrometers, coordinate measuring machines (CMMs), laser scanners, optical comparators, or profilometers. Measurements are taken at specific points or locations on the object or part and compared to the specified tolerances to determine if they fall within the acceptable range.

Advantages

Dimensional inspection offers several advantages. Firstly, it provides precise and accurate measurements, allowing for the detection of small deviations or variations in dimensions. This can help ensure the proper fit, function, and performance of the object or part. Dimensional inspection also enables the identification of dimensional defects or issues that may affect the overall quality or usability of the product. Additionally, it provides objective and quantifiable data that can be used for quality control, process improvement, or product development purposes.

Limitations

Despite its advantages, dimensional inspection also has limitations. One limitation is that it is a time-consuming and labor-intensive process, particularly when dealing with complex or intricate objects or parts. It requires skilled technicians or operators who are trained in using the measurement tools and interpreting the results accurately. Additionally, dimensional inspection may not detect certain defects or issues that are not directly related to dimensions, such as surface finish, material properties, or functional performance. It is also important to consider environmental factors that may affect dimensional measurements, such as temperature, humidity, or vibrations.

Surface Inspection

Definition

Surface inspection is a type of inspection method that focuses on evaluating the surface characteristics of an object or material. It involves examining the physical properties, conditions, or flaws present on the surface to assess its quality, integrity, or suitability for a specific purpose.

Process

The process of surface inspection typically involves visually examining the surface for irregularities, defects, contaminants, or damages. It may also involve using specialized equipment or techniques such as magnification, surface profilometry, or surface roughness measurement to obtain more detailed information about the surface features. Surface inspection can be performed using various methods, including visual inspection, microscopy, optical scanning, or non-contact surface measurement.

Advantages

Surface inspection offers several advantages. Firstly, it allows for the detection and identification of surface defects or issues that may affect the appearance, performance, or functionality of the object or material. This can help ensure the overall quality and reliability of the product. Surface inspection also provides valuable information about surface roughness, texture, or finish, which may be critical in certain applications or industries. Additionally, it allows for the assessment of surface properties such as hardness, adhesion, cleanliness, or corrosion resistance.

Limitations

Surface inspection has some limitations that need to be considered. One limitation is that it primarily focuses on surface-level characteristics and may not provide insights into internal or hidden defects or issues. This means that it may not be suitable for assessing the overall structural integrity or internal quality of an object or material. Additionally, surface inspection is subjective and may be influenced by factors such as lighting conditions or human error. It is also important to consider the limitations of the specific surface measurement techniques or equipment used, as they may have their own accuracy, resolution, or range constraints.

Non-Destructive Testing

Definition

Non-destructive testing (NDT) is a type of inspection method that allows for the assessment of the internal quality, integrity, or performance of an object or material without causing any damage or alteration to its structure or properties. It involves the use of various techniques to detect and evaluate defects, flaws, or abnormalities without the need for destructive techniques such as cutting, drilling, or disassembling.

Process

The process of non-destructive testing typically involves the use of specialized equipment or techniques that can measure, analyze, or detect certain physical properties or signals. Common NDT techniques include ultrasonic testing, radiographic testing, magnetic particle testing, liquid penetrant testing, eddy current testing, or thermal imaging. Each technique utilizes different physical principles or properties to identify or indicate the presence of defects or discontinuities in the object or material being inspected.

Advantages

Non-destructive testing offers several advantages. Firstly, it allows for the inspection of an object or material without causing any damage, preserving its structural integrity or functional properties. This is particularly important when dealing with high-value or critical components or systems where destructive testing is not feasible. NDT also provides the ability to inspect and assess a large volume or area of an object or material in a relatively short amount of time. Additionally, it provides objective and quantitative data that can be used for quality control, safety assessment, or maintenance decision-making.

Limitations

Despite its advantages, non-destructive testing also has limitations. One limitation is that it may not be able to detect certain types of defects or issues that are beyond the capabilities of the specific NDT technique used. This means that multiple NDT techniques may need to be employed to achieve comprehensive inspection coverage. Additionally, NDT requires specialized equipment, training, and expertise, which may add complexity and cost to the inspection process. It is important to consider the limitations and reliability of the specific NDT technique used, as they may be influenced by factors such as material properties, geometry, or accessibility of the object or material being inspected.