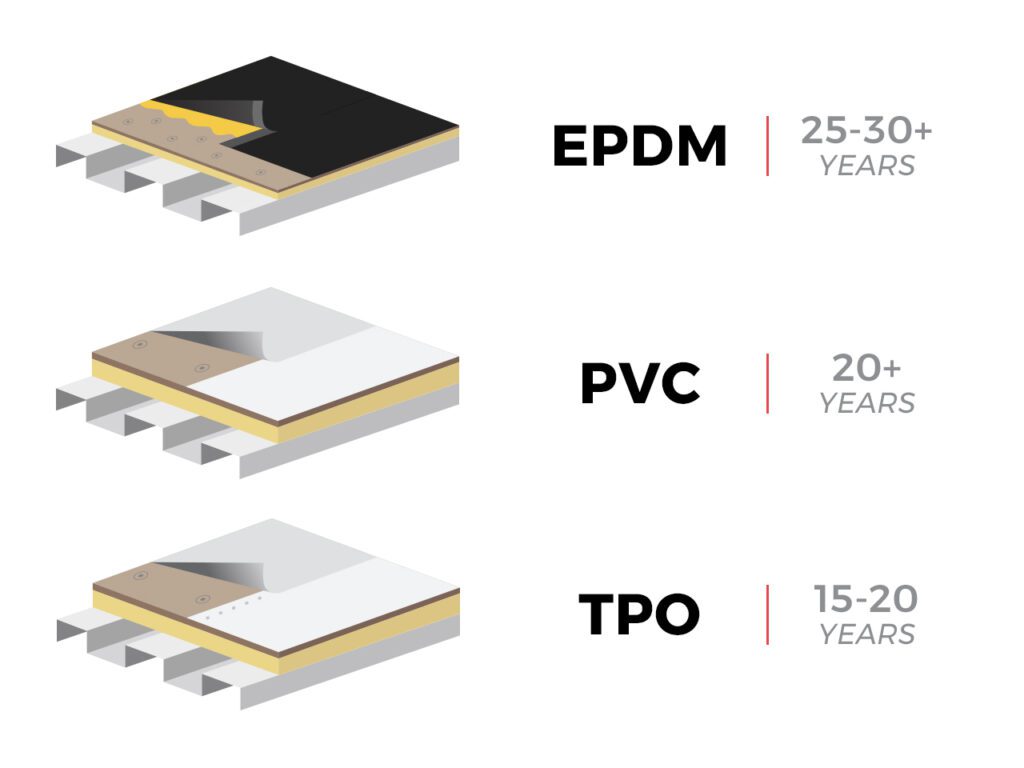

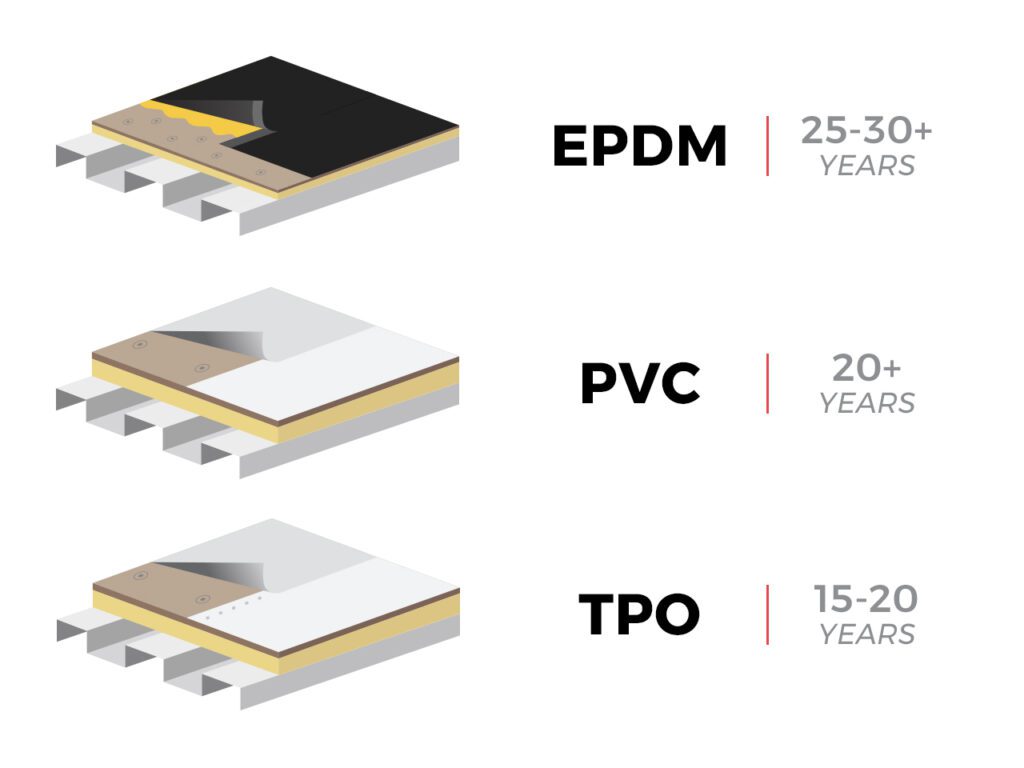

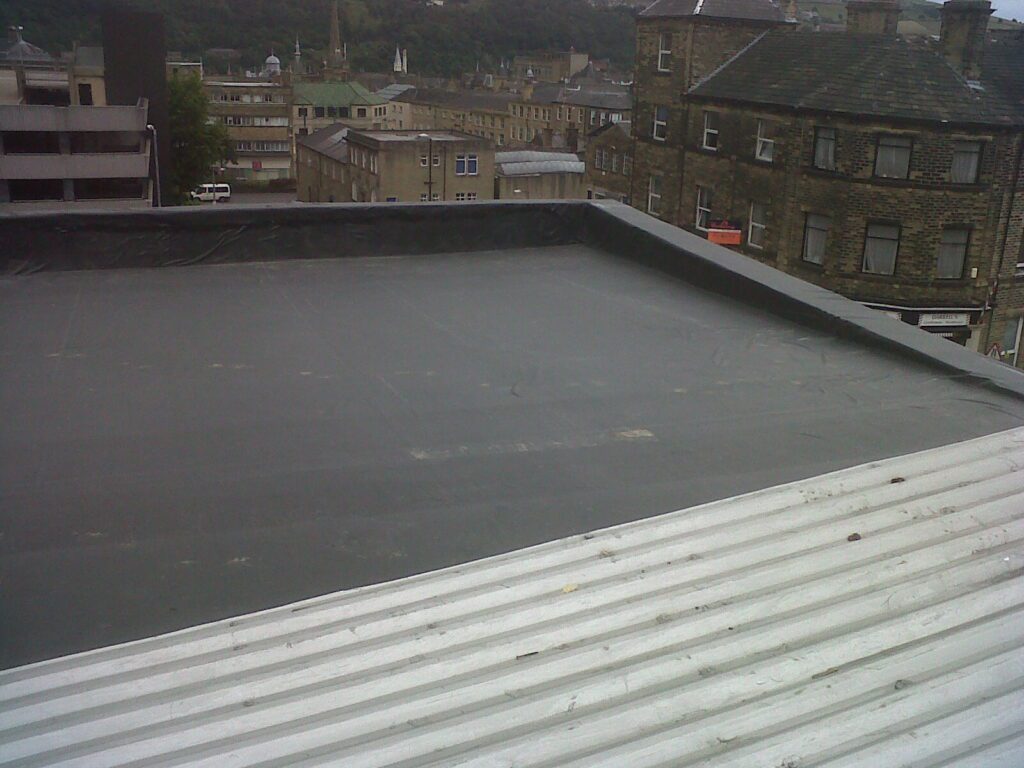

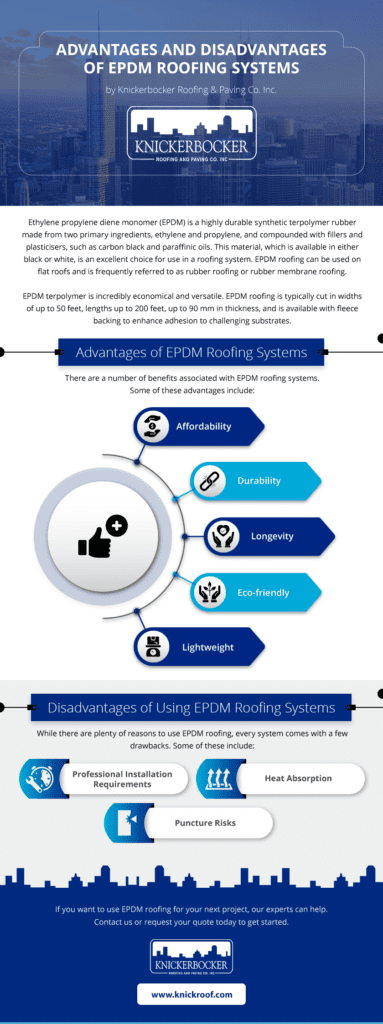

EPDM, or Ethylene Propylene Diene Monomer, is a popular roofing material known for its durability and longevity. Made from a synthetic rubber compound, EPDM roofs have gained widespread recognition for their ability to withstand harsh weather conditions, UV radiation, and even hailstorms. With proper installation and regular maintenance, an EPDM roof can last up to 30 years or more, providing homeowners with peace of mind and long-term protection against the elements. In this article, we will explore the factors that determine the lifespan of an EPDM roof and offer valuable insights on extending its longevity. Whether you’re considering EPDM for your new roof or currently have one installed, stay tuned to discover the secrets behind its impressive durability.

Factors Affecting EPDM Roof Lifespan

Installation Quality

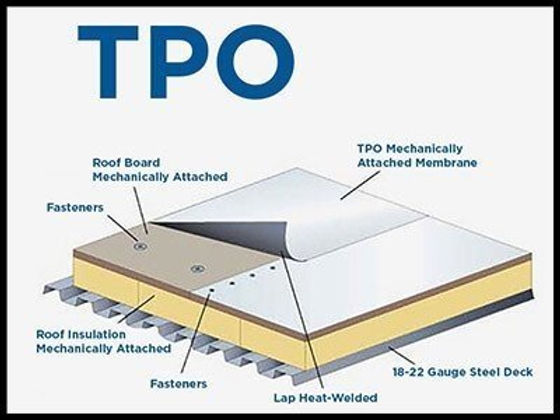

The lifespan of an EPDM roof heavily depends on the quality of its installation. Proper installation by trained professionals ensures that the roof is securely fastened and effectively sealed. This prevents the risk of leaks and premature deterioration of the membrane.

Climate and Weather Conditions

The climate and weather conditions in a particular location can significantly impact the lifespan of an EPDM roof. EPDM roofs are known for their ability to withstand a wide range of weather conditions, including extreme heat, cold, and strong winds. However, prolonged exposure to harsh weather such as intense sunlight, heavy rain, and snow can gradually degrade the roof’s surface and reduce its lifespan.

UV Exposure

One of the primary factors that can shorten the lifespan of an EPDM roof is constant exposure to UV (ultraviolet) rays from the sun. Over time, these rays can cause the rubber membrane to weaken, resulting in cracks, blistering, and surface degradation. To combat this, EPDM roofs are often coated with UV-protective products or painted with reflective coatings that help in reducing the harmful effects of UV exposure.

Chemical Exposure

EPDM roofs may come into contact with various chemicals, such as air pollutants, industrial effluents, and harsh cleaning solutions. The exposure to these chemicals can cause the rubber membrane to deteriorate more quickly, leading to premature aging and potential leaks. Regular cleaning and avoiding the use of harsh chemicals can help extend the lifespan of an EPDM roof.

Ponding Water

Ponding water occurs when water accumulates and remains on the EPDM roof for an extended period. This can be a result of improper drainage or low spots on the roof surface. Ponding water can weaken the membrane and increase the likelihood of leaks and deterioration. Proper roof slope and drainage system design play a crucial role in preventing ponding water and preserving the lifespan of the EPDM roof.

Roof Traffic and Maintenance

The amount of foot traffic on an EPDM roof can impact its lifespan. Excessive foot traffic can cause the membrane to wear down faster, leading to potential damage and leaks. Additionally, regular maintenance is essential to ensure that any small issues are promptly addressed before they escalate into more significant problems. Routine inspections, gutter cleaning, and repairs contribute to extending the lifespan of an EPDM roof.

Vandalism and Accidental Damage

Vandalism and accidental damage can significantly impact the lifespan of an EPDM roof. Acts of vandalism or improper handling of equipment on the roof can result in cuts, punctures, or tears in the rubber membrane, compromising its integrity. Avoiding unauthorized access to the roof and promptly repairing any damages is crucial to maintaining the longevity of an EPDM roof.

Buildup of Debris and Vegetation

The accumulation of debris, such as leaves, branches, and dirt, can accelerate the deterioration of an EPDM roof. Debris traps moisture, which can lead to mold and algae growth, causing the membrane to deteriorate faster. Additionally, the growth of vegetation on the roof surface can puncture or damage the EPDM membrane. Regular cleaning and removing any accumulated debris and vegetation are essential for preserving the lifespan of an EPDM roof.

Roof Slope and Drainage

The slope and drainage design of the roof are important factors in determining the lifespan of an EPDM roof. A proper slope ensures that water drains off the roof efficiently, reducing the risk of water accumulation and potential damage. Inadequate drainage can lead to ponding water, which can weaken the membrane and shorten the roof’s lifespan. Proper roof design should incorporate effective slope and drainage systems to maximize the longevity of an EPDM roof.

Insulation and Ventilation

The presence of proper insulation and ventilation in the building can also affect the lifespan of an EPDM roof. Adequate insulation reduces heat transfer and helps maintain stable temperatures, reducing the stress on the roof membrane. Proper ventilation helps remove excess moisture, preventing the buildup of humidity and potential damage to the EPDM roof. A well-insulated and ventilated building can contribute to extending the lifespan of an EPDM roof.

Typical EPDM Roof Lifespan

Commercial vs Residential Roofs

The lifespan of an EPDM roof can vary depending on whether it is installed on a commercial or residential building. Generally, EPDM roofs on commercial buildings tend to have a longer lifespan compared to residential roofs. This is because commercial roofs often have better maintenance practices, fewer foot traffic instances, and larger, more robust drainage systems. Residential roofs, on the other hand, may experience more wear and tear due to foot traffic and may have smaller drainage systems, which can impact the overall lifespan of the roof.

EPDM Product Quality

The quality of the EPDM roofing product itself plays a significant role in determining its lifespan. EPDM membranes come in various grades and thicknesses, ranging from thinner economy-grade membranes to thicker, more durable options. High-quality EPDM products typically have a longer lifespan due to their enhanced resistance to UV rays, chemical exposure, and weather conditions. Investing in a reputable and reliable EPDM product can help ensure a longer lifespan for the roof.

Thickness of the Membrane

The thickness of the EPDM membrane can directly impact its lifespan. Thicker EPDM membranes generally offer increased durability and resistance to wear, tear, and punctures. Thicker membranes can better withstand harsh weather conditions and have a higher tolerance for foot traffic. Therefore, opting for a thicker EPDM membrane during installation can extend the overall lifespan of the roof.

Seaming and Adhesive Quality

The quality of seaming and adhesive used during the installation of an EPDM roof is critical to its longevity. Properly sealed and bonded seams ensure that the EPDM membrane remains intact and effectively guards against water infiltration. If the seaming or adhesive quality is compromised, the roof becomes susceptible to leaks and potential damage. Attention to detail during the installation process, including ensuring strong and secure seams, can significantly contribute to the lifespan of an EPDM roof.

Maintenance and Inspections

Regular maintenance and inspections are vital for extending the lifespan of an EPDM roof. Routine inspections help identify and address any potential issues before they escalate and cause significant damage. Maintenance tasks, such as gutter cleaning, removing debris, and repairing small leaks, can prevent further deterioration. By staying on top of maintenance and regularly inspecting the roof, the lifespan of an EPDM roof can be maximized.

Proper Roof Design and Installation

Proper roof design and installation are crucial factors that can extend the lifespan of an EPDM roof. The roof should be designed to ensure proper slope and drainage, which helps prevent ponding water and potential damage. Additionally, employing experienced and skilled professionals for the installation ensures that the roof is correctly installed, minimizing the risk of premature aging or leaks. Adhering to industry best practices for roof design and installation significantly contributes to the overall lifespan of an EPDM roof.

Manufacturer’s Warranty

The length and coverage of the manufacturer’s warranty can provide insight into the expected lifespan of an EPDM roof. Reputable manufacturers often offer warranties that cover a specified number of years, typically ranging from 20 to 30 years. The warranty gives confidence in the quality and durability of the EPDM product and assures the building owner that the roof is expected to last for the stated duration. Checking and understanding the terms of the manufacturer’s warranty is essential for managing expectations regarding the lifespan of an EPDM roof.

Geographic Location

The geographic location of a building can have a significant impact on the lifespan of an EPDM roof. Different regions experience varying climate conditions, temperature ranges, and levels of UV radiation. Regions with harsh climates or high UV exposure tend to have roofs that deteriorate faster. Buildings located in areas prone to extreme weather events, such as hurricanes or heavy snowfall, may also have roofs that have a shorter lifespan. Understanding the local climate and weather patterns is important for estimating the expected lifespan of an EPDM roof in a specific area.

Building Use and Occupancy

The purpose and occupancy of the building can influence the lifespan of an EPDM roof. Buildings with high foot traffic, such as commercial buildings or public facilities, may experience more wear and tear on the roof surface. Additionally, buildings with equipment installed on the roof, such as HVAC units or solar panels, may require more frequent maintenance and inspections. The intensity and frequency of use can impact the overall lifespan of the EPDM roof.

Exposure to Chemicals and Effluent

The exposure of an EPDM roof to chemicals and effluents can significantly impact its lifespan. Buildings near industrial areas or facilities with chemical emissions may subject the EPDM roof to potentially harmful substances. These chemicals can lead to accelerated degradation of the roof membrane and reduce its overall lifespan. A careful assessment of the nearby environment and its potential for chemical exposure should be considered when estimating the lifespan of an EPDM roof.

Factors that Can Shorten EPDM Roof Lifespan

Installation Errors

Improper installation of an EPDM roof can significantly shorten its lifespan. Errors such as inadequate membrane attachment, improper seam sealing, or incorrect use of adhesives can compromise the roof’s integrity. These mistakes can result in leaks, premature aging, and overall reduced performance of the roof. Proper training and expertise during the installation process are crucial to avoid these errors and ensure a longer lifespan for the EPDM roof.

Excessive Wear and Tear

Excessive wear and tear can considerably shorten the lifespan of an EPDM roof. Factors such as heavy foot traffic, equipment movement, or storing heavy objects on the roof can cause the membrane to deteriorate faster. Abrasion from these activities gradually weakens the EPDM membrane, making it more prone to leaks and damage. Implementing measures to limit foot traffic and properly handling equipment can help minimize wear and tear and extend the lifespan of the EPDM roof.

Neglected Maintenance

Neglecting regular maintenance tasks and inspections can lead to the early failure of an EPDM roof. Failure to address minor issues promptly can result in more significant damage over time. Negligence in performing routine maintenance tasks, such as debris removal or gutter cleaning, can also allow moisture to accumulate and accelerate the roof’s deterioration. Regular maintenance is essential for identifying and addressing potential problems to prevent premature aging and extend the lifespan of an EPDM roof.

Harsh Climate and Weather Events

EPDM roofs exposed to harsh climate conditions and severe weather events are more susceptible to premature aging. Intense sunlight, extreme temperatures, heavy rain, snow, and hail can cause the EPDM membrane to degrade faster. These weather events can result in cracks, blistering, or punctures, compromising the roof’s ability to effectively protect the building. While EPDM roofs are designed to withstand various weather conditions, prolonged exposure to particularly harsh environments can shorten their lifespan.

Unauthorized Modifications

Unauthorized modifications or additions to an EPDM roof can have negative consequences on its lifespan. Cutting or puncturing the membrane to install new equipment, patching with incompatible materials, or making unauthorized changes to the roof structure can compromise its integrity. These modifications can introduce weak points where leaks can occur or accelerate the deterioration of the EPDM membrane. Proper authorization and professional consultation should be sought when considering any modifications to an EPDM roof.

Incompatible Roofing System Components

The compatibility of different roofing system components can significantly affect the lifespan of an EPDM roof. The use of incompatible materials, such as incompatible adhesives or sealants, can cause the EPDM membrane to degrade prematurely. It is important to ensure that all components of the roofing system, including insulation, flashing, and sealants, are compatible with EPDM to ensure optimal performance and maximize the roof’s lifespan.

Lack of Proper Drainage

Inadequate or poorly designed drainage systems can lead to the accumulation of water and potential damage to the EPDM roof. Without proper drainage, ponding water can occur, causing the membrane to deteriorate. Insufficient drainage also increases the time it takes for the roof to dry after rain or other weather events, which can contribute to the growth of mold, mildew, or algae. Proper roof design and installation with effective drainage systems are essential for avoiding ponding water and maximizing the lifespan of an EPDM roof.

Improper Storage and Handling

Improper storage and handling of EPDM materials can have negative consequences on the lifespan of the roof. EPDM membranes should be stored in a cool, dry, and protected environment to prevent damage from excessive heat, sunlight, or moisture. Mishandling of the EPDM rolls during transport or installation can result in punctures, tears, or creases, compromising the integrity of the membrane. Following proper storage and handling procedures is crucial to preserving the quality and maximizing the lifespan of an EPDM roof.

Environmental Pollution

Buildings located in areas with high levels of environmental pollution may experience a shorter lifespan for their EPDM roofs. Air pollutants, industrial emissions, and other contaminants can cause the EPDM membrane to deteriorate more quickly. Acid rain and chemical fallout from nearby factories or industrial processes can chemically react with the EPDM surface, leading to premature aging and reduced performance of the roof. The impact of environmental pollution should be considered when estimating the lifespan of an EPDM roof.

Negligence and Vandalism

Negligence and acts of vandalism can significantly shorten the lifespan of an EPDM roof. Failure to promptly address maintenance issues or neglecting the roof’s care can lead to accelerated deterioration. Intentional acts of vandalism, such as cutting or puncturing the membrane, can compromise the roof’s integrity and result in leaks and damage. It is crucial to implement preventative measures, ensure proper maintenance, and discourage unauthorized access to the roof to protect the lifespan of an EPDM roof.

Extending the Lifespan of EPDM Roofs

Regular Inspections and Maintenance

Regular inspections and maintenance are essential for extending the lifespan of an EPDM roof. A comprehensive inspection schedule, including visual inspections and checks for any signs of damage, should be established. Maintenance tasks, such as cleaning gutters, removing debris, and repairing minor issues, should be performed promptly. Regular inspections and maintenance help identify and address potential problems early, preventing further damage and prolonging the lifespan of the EPDM roof.

Prompt Repairs of Damages

Promptly addressing any damages to an EPDM roof is crucial to prevent further deterioration and extend its lifespan. Spotting signs of damage, such as cracks, punctures, or areas of degradation, should prompt immediate repairs. Small repairs can prevent leaks and additional damage from spreading, maintaining the roof’s integrity and functionality. Quick response and professional repair services are key to maximizing the lifespan of an EPDM roof.

Keeping the Roof Clean and Debris-Free

Regularly cleaning the EPDM roof and keeping it free of debris is vital to its longevity. Removing leaves, branches, dirt, and other debris prevents moisture buildup and reduces the risk of mold or algae growth. Periodic cleaning helps maintain the effectiveness of the EPDM membrane and avoids potential damage caused by debris accumulation. Implementing a regular cleaning schedule is a simple yet effective way to extend the lifespan of an EPDM roof.

Avoiding Heavy Foot Traffic

Limiting foot traffic on an EPDM roof can help minimize wear and tear and extend its lifespan. Heavy foot traffic can cause the membrane to weaken and eventually lead to leaks or damage. Whenever possible, establish designated pathways or avoid unnecessary access to the roof. Educating occupants and employees about the importance of minimizing foot traffic can contribute to preserving the integrity of an EPDM roof.

Proper Drainage Design

Proper drainage design is crucial for maximizing the lifespan of an EPDM roof. The roof should be sloped correctly to ensure efficient water runoff and prevent ponding. Adequate installation of gutters, downspouts, and drains helps channel water away from the roof surface, reducing the risk of damage. Working with experienced professionals to design and install an efficient drainage system is essential to prolonging the lifespan of an EPDM roof.

Professional Installation and Repair Services

EPDM roofs should be installed and repaired by experienced professionals to ensure optimal performance and longevity. Professional contractors have the necessary expertise to correctly install or repair the EPDM membrane, ensuring that it is bonded and sealed correctly. Their knowledge and experience help avoid common installation errors and ensure that the EPDM roof functions at its best, extending its lifespan.

Avoiding Chemical Exposure

Minimizing exposure to chemicals and effluents can help extend the lifespan of an EPDM roof. Identifying potential sources of chemical exposure, such as nearby industrial facilities, and implementing measures to mitigate their impact is important. This can include minimizing contact with chemicals during cleaning or maintenance processes and choosing cleaning products that are safe for EPDM. Taking precautions to limit chemical exposure helps preserve the integrity of the EPDM membrane and extend the lifespan of the roof.

Timely Replacement of Old Roofs

EPDM roofs, like any other roofing system, have a limited lifespan. It is crucial to recognize when the roof has reached the end of its serviceable life and arrange for its timely replacement. Neglecting an old and failing EPDM roof can lead to extensive damage, leaks, and costlier repairs. Keeping track of the age and condition of the EPDM roof and proactively planning for its replacement ensures the building remains protected and minimizes the risk of potential issues.

Application of UV-Reflective Coatings

UV-reflective coatings can be applied to the EPDM roof to provide an extra layer of protection against UV exposure. These coatings help reduce the impact of UV rays on the EPDM membrane, slowing down degradation and extending the roof’s lifespan. UV-reflective coatings also contribute to energy efficiency by reducing heat absorption, which can in turn help lower cooling costs for the building. Investing in UV-reflective coatings is a proactive measure to enhance the performance and extend the lifespan of an EPDM roof.

Improving Insulation and Ventilation

Proper insulation and ventilation play a crucial role in prolonging the lifespan of an EPDM roof. Effective insulation helps maintain stable temperatures, reducing stress on the roof and minimizing thermal expansion and contraction. Improved ventilation helps remove excess moisture and prevent the buildup of humidity, reducing the risk of mold or algae growth. Ensuring the building has adequate insulation and ventilation systems helps maximize the longevity of an EPDM roof.

In conclusion, the lifespan of an EPDM roof is influenced by various factors, including installation quality, climate conditions, UV exposure, chemical exposure, ponding water, roof traffic, maintenance, vandalism, debris buildup, roof slope, insulation, and ventilation. Considering these factors, along with the quality of the EPDM product, thickness of the membrane, seaming and adhesive quality, maintenance and inspections, proper roof design and installation, manufacturer’s warranty, geographic location, building use and occupancy, and exposure to chemicals, helps estimate and maximize the lifespan of an EPDM roof. By addressing potential factors that can shorten the lifespan of the roof and implementing measures to extend its longevity, building owners can make the most of their investment in an EPDM roof.