EPDM roofing is a highly durable and versatile roofing material that is becoming increasingly popular among homeowners and commercial property owners. EPDM stands for Ethylene Propylene Diene Monomer, which is a synthetic rubber. This type of roof is known for its exceptional resistance to weather elements, including sunlight, hail, and extreme temperatures, making it an excellent choice for various climates. In addition to its durability, EPDM roofs are also known for their easy installation and low maintenance requirements, making them a cost-effective option in the long run. Whether you are looking to replace an existing roof or considering a new installation, understanding what an EPDM roof entails will help you make an informed decision for your property.

What is an EPDM Roof?

An EPDM roof refers to a roofing system that utilizes EPDM (Ethylene Propylene Diene Monomer), a type of synthetic rubber, as the primary material. EPDM roofs have gained immense popularity in the roofing industry due to their durability, versatility, and cost-effectiveness. They are commonly used for both residential and commercial buildings and are known for their exceptional weather resistance, longevity, and ease of installation. In this article, we will explore the definition, history, advantages, and disadvantages of EPDM roofs, as well as their installation process, materials, systems, maintenance, and a comparison with other roofing materials.

Definition of EPDM Roof

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic rubber membrane that is commonly used in roofing applications. It is primarily composed of ethylene and propylene, with a small amount of diene added to enhance its flexibility and UV resistance. EPDM roofs consist of large sheets of this rubber membrane that are installed over the roof substrate to protect the building from the elements. EPDM roofs are known for their excellent weather resistance, withstanding extreme temperatures, UV radiation, and even hailstorms.

History of EPDM Roofs

EPDM roofs have a rich history that dates back to the early 1960s when they were first introduced as a roofing material. The initial development of EPDM rubber was focused on creating an effective and affordable waterproofing solution for various industries, including roofing. Manufacturers quickly recognized the potential of EPDM rubber due to its unique properties, such as its resistance to sunlight, ozone, and weathering.

In the early years, EPDM roofs were mainly used in commercial and industrial buildings, where their durability and low maintenance requirements made them an ideal choice. As the roofing industry evolved and the demand for better roofing materials grew, EPDM roofs started gaining popularity in the residential sector as well. Today, EPDM roofs are one of the most commonly installed roofing systems across various types of buildings.

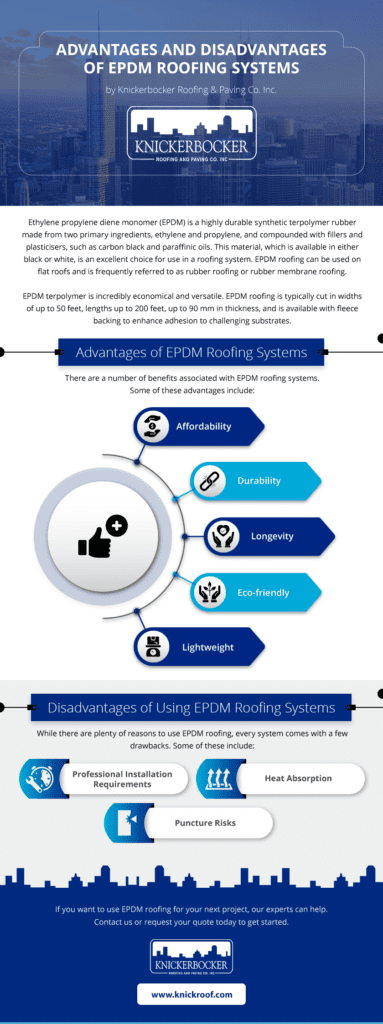

Advantages of EPDM Roofs

EPDM roofs offer several advantages that make them a popular choice for both residential and commercial applications. Firstly, EPDM roofs are highly durable and have a long lifespan. They can typically last up to 30 years or even more with proper care and maintenance. Additionally, EPDM roofs are known for their high weather resistance, withstanding extreme temperatures, heavy rain, and even hailstorms.

Another significant advantage of EPDM roofs is their cost-effectiveness. Compared to many other roofing materials, EPDM is relatively affordable and provides excellent value for money. EPDM roofs are also relatively easy to install, making the installation process quicker and more straightforward compared to some other roofing systems.

EPDM roofs are also highly flexible, allowing them to adapt to the shape and movement of the building. This flexibility helps prevent cracks and leaks, ensuring that the roof stays watertight and in optimal condition. Furthermore, EPDM roofs are resistant to UV radiation, ozone, and various chemicals, making them highly resistant to degradation and preserving their appearance over time.

Disadvantages of EPDM Roofs

While EPDM roofs offer numerous advantages, it is important to consider their potential disadvantages as well. One of the main drawbacks of EPDM roofs is their susceptibility to punctures. Sharp objects, such as falling branches or tools, can potentially cause small punctures in the membrane, leading to leaks if not repaired promptly.

EPDM roofs can also be vulnerable to standing water. If water accumulates on the roof for an extended period, it can degrade the adhesive used in the installation process and compromise the integrity of the membrane. Therefore, proper drainage and regular inspections are essential to prevent any potential issues.

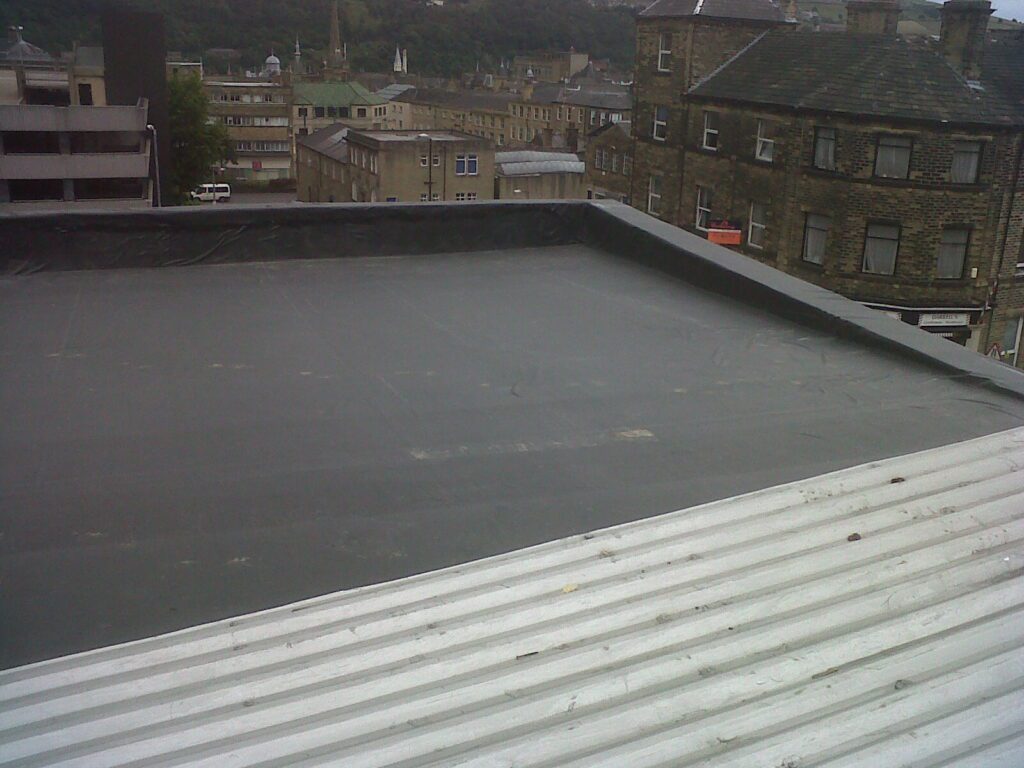

Another limitation of EPDM roofs is their aesthetic appeal. EPDM roofs typically come in black or dark gray color options, which may not be visually appealing to some homeowners or architects who prefer a wider range of colors and styles for their roofing materials.

EPDM Roofing Installation Process

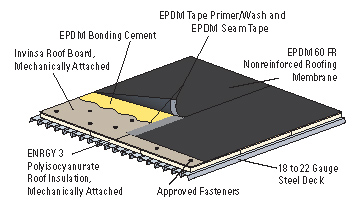

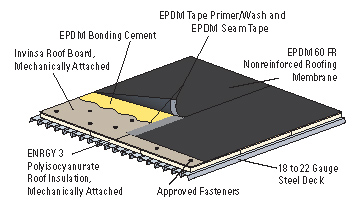

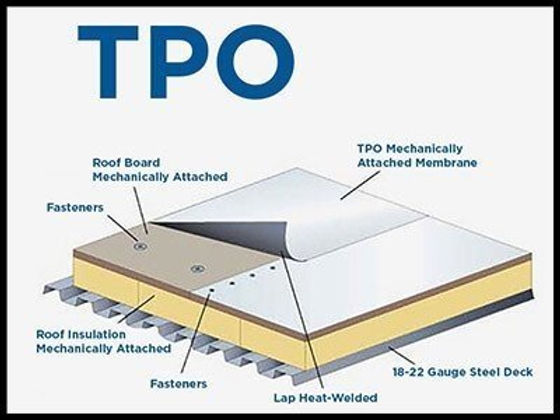

The installation of an EPDM roof involves several steps to ensure a proper and watertight installation. Before the installation begins, the existing roof substrate is thoroughly inspected, and any necessary repairs or adjustments are made. The EPDM membrane is then laid out over the roof, ensuring it covers the entire surface area and edges.

To adhere the EPDM membrane to the roof substrate, various methods can be used, such as ballasting, mechanical fasteners, or adhesive bonding. The specific installation technique depends on factors such as the size and complexity of the roof, local building codes, and the preferences of the roofing contractor.

After the EPDM membrane is securely attached to the roof substrate, the seams and edges are sealed with a specialized EPDM adhesive or tape to ensure a watertight seal. This step is crucial in preventing any potential leaks or water infiltration.

During the installation process, it is important to follow the manufacturer’s guidelines and recommendations to ensure a proper installation that maximizes the longevity and performance of the EPDM roof.

EPDM Roofing Materials

EPDM roofs primarily consist of the EPDM rubber membrane, which is the key component responsible for providing weather resistance and waterproofing. The EPDM membrane is available in various thicknesses, typically ranging from 45 mils to 90 mils, to accommodate different application requirements.

In addition to the EPDM membrane, other materials are also used during the installation process, such as adhesive, seam tape, and fasteners. These materials help secure and seal the EPDM membrane, ensuring proper installation and water resistance.

EPDM Roofing Systems

EPDM roofs can be installed using different systems, depending on the specific needs and requirements of the building. The two primary EPDM roofing systems are ballasted systems and fully adhered systems.

Ballasted EPDM roofing systems involve laying the EPDM membrane over the roof substrate and then covering it with loose stone or pavers to provide weight and resistance against wind uplift. This system is commonly used in commercial applications and is known for its ease of installation and cost-effectiveness.

Fully adhered EPDM roofing systems, on the other hand, involve attaching the EPDM membrane directly to the roof substrate using adhesive or bonding agents. This system provides superior wind uplift resistance and is commonly used in buildings with complex roof designs or areas prone to high winds.

EPDM Roof Maintenance

Proper maintenance is essential for maximizing the lifespan and performance of an EPDM roof. Regular inspections should be conducted to identify any signs of damage or wear, such as punctures, seam separation, or membrane degradation. Any identified issues should be addressed promptly to prevent further damage and potential leaks.

Routine cleaning is also recommended to remove debris, dirt, and other contaminants that can accumulate on the roof surface. This can be done using a soft-bristle brush or a mild detergent solution. However, harsh chemicals or abrasive cleaning methods should be avoided, as they can damage the EPDM membrane.

Additionally, it is important to ensure proper drainage to prevent the accumulation of standing water on the roof. Clearing any clogged gutters or downspouts and maintaining a well-functioning drainage system is crucial in preventing potential issues with an EPDM roof.

Common Issues with EPDM Roofs

While EPDM roofs are known for their durability and weather resistance, certain common issues can arise over time. One of the main issues is membrane shrinkage, which can occur due to prolonged exposure to extreme temperatures or inadequate installation. This can cause the seams to separate or the membrane to pull away from the roof edges, potentially leading to leaks.

Ponding, or the accumulation of standing water on the roof, is another issue that can affect EPDM roofs. If left unaddressed, ponding water can degrade the adhesive used during installation and compromise the integrity of the membrane, increasing the risk of leaks and water infiltration.

Excessive foot traffic on an EPDM roof can also cause problems, as it can lead to punctures or tears in the membrane. Therefore, it is important to limit foot traffic on the roof and use walkways or designated paths to minimize the risk of damage.

EPDM Roof vs. Other Roofing Materials

EPDM roofs offer several advantages compared to other roofing materials commonly used in residential and commercial applications. In terms of durability, EPDM roofs have a longer lifespan compared to traditional asphalt shingles, which typically last 20 to 30 years. EPDM roofs also outperform many other roofing materials when it comes to weather resistance, especially in extreme temperatures and harsh climates.

EPDM roofs are generally more cost-effective compared to premium roofing materials like metal or slate. The initial installation costs of EPDM roofs are relatively lower, and their long lifespan reduces the need for frequent repairs or replacements, resulting in long-term cost savings.

When compared to other flat roofing systems, such as built-up roofs or modified bitumen roofs, EPDM roofs offer easier installation and maintenance. The large EPDM membrane sheets can be quickly and efficiently installed, reducing labor costs and installation time. Additionally, EPDM roofs require minimal maintenance compared to built-up roofs, which often require regular resealing and re-coating.

However, it is important to note that EPDM roofs may not offer the same aesthetic appeal as some other roofing materials, such as clay or concrete tiles. EPDM roofs typically come in limited color options, primarily black or dark gray, which may not suit the architectural style or personal preferences of some homeowners.

In conclusion, EPDM roofs are a versatile and cost-effective roofing solution that offers excellent weather resistance, durability, and ease of installation. Although they have certain limitations and common issues, proper maintenance and regular inspections can help ensure their longevity and performance. When considering different roofing materials, it is essential to weigh the specific needs, budget, and aesthetic preferences to determine if an EPDM roof is the right choice for your building.