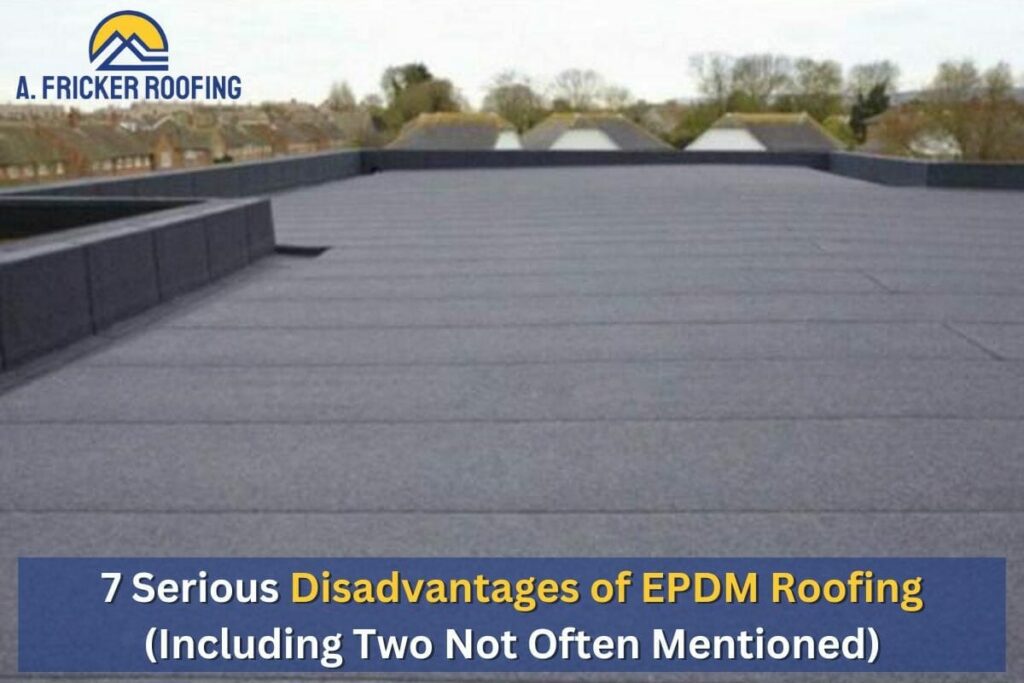

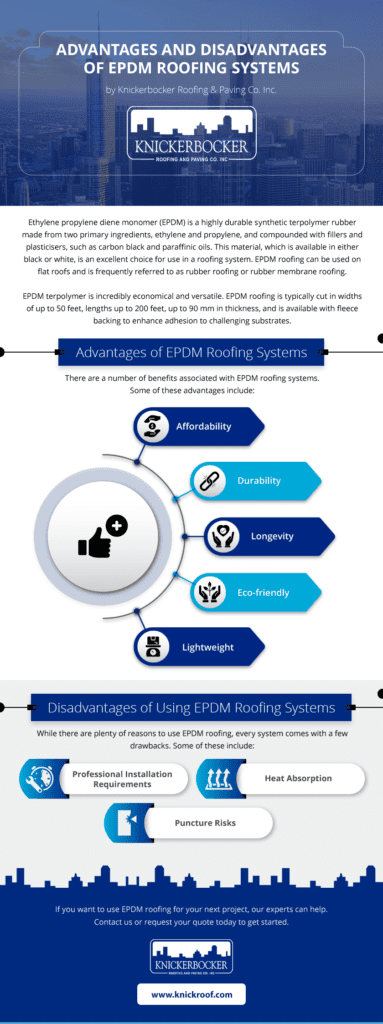

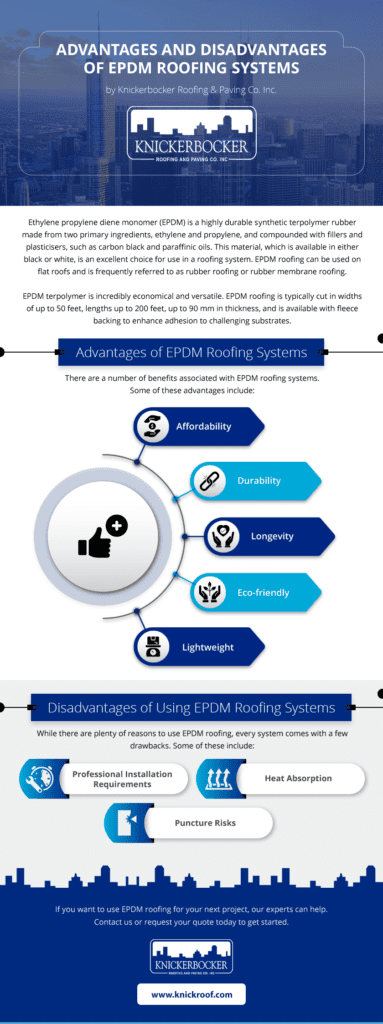

EPDM, an acronym for Ethylene Propylene Diene Monomer, is a widely used synthetic rubber material known for its excellent weather resistance and durability. However, like any product, EPDM does have its disadvantages. Some of the notable drawbacks include its limited resistance to oils, greases, and certain solvents, making it less suitable for applications in environments where exposure to these substances is common. Additionally, EPDM may not withstand high temperatures as well as other materials, making it less ideal for certain industrial settings. Despite these drawbacks, EPDM remains a popular choice for various applications due to its outstanding weatherability and cost-effectiveness.

Durability

Limited lifespan in certain applications

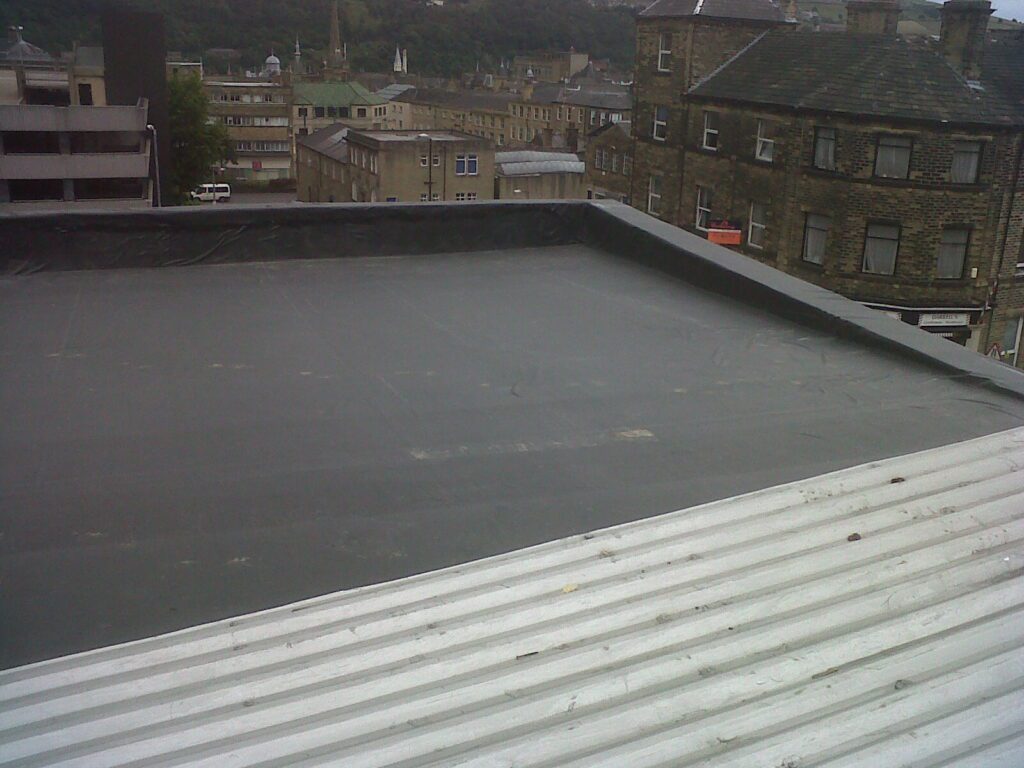

EPDM (Ethylene Propylene Diene Monomer) roofing membranes have a limited lifespan in certain applications. While they can last for up to 20 years in ideal conditions, EPDM may not perform as well in environments with extreme weather conditions or heavy foot traffic. The constant exposure to harsh elements such as UV radiation, rain, snow, and hail can cause the membrane to deteriorate over time.

Susceptibility to punctures and tears

Another disadvantage of EPDM roofing is its susceptibility to punctures and tears. The rubber material used in EPDM membranes can be easily damaged by sharp objects, such as falling branches or tools accidentally dropped on the roof. This vulnerability to punctures and tears can compromise the integrity of the roof and lead to leaks, requiring timely repairs to prevent further damage to the structure.

Installation

Complex and time-consuming process

Installing an EPDM roof is a complex and time-consuming process that requires careful attention to detail. It involves several steps, such as surface preparation, adhesive application, and membrane installation. Each of these steps demands precision and expertise to ensure a proper and secure installation.

Requires skilled professionals

Due to the complexity of the installation process, EPDM roofs require skilled professionals to perform the job. Improper installation can lead to various issues, including leaks, membrane shrinkage, and premature wear and tear. Hiring experienced roofing contractors who specialize in EPDM installations is crucial to ensure a successful and long-lasting roof.

Repairs

Difficult to repair large damages

Repairing large damages on an EPDM roof can be a challenging task. The repair process often involves removing and replacing entire sections of the membrane, which requires expertise and proper equipment. This can result in higher repair costs and longer downtime for the building occupants.

Requires removing and replacing entire sections

EPDM roofs are designed to be seamless, but when repairs are necessary, the damaged sections may need to be removed and replaced entirely. This can be an expensive and time-consuming endeavor, especially if the damage is extensive. Additionally, removing and replacing sections of the membrane can disrupt the overall integrity of the roof and increase the risk of future leaks.

Cost

Higher initial cost compared to other roofing materials

One disadvantage of EPDM roofing is its higher initial cost compared to other roofing materials such as asphalt shingles or metal roofs. The cost of EPDM membrane rolls, adhesives, and installation can add up, making it a more significant investment upfront.

Expense of professional installation

EPDM roof installation requires professional expertise, which adds to the overall cost. Hiring skilled roofing contractors who specialize in EPDM roofs can be expensive, but it is necessary to ensure a proper and durable installation. The expense of professional installation should be factored into the overall budget when considering EPDM as a roofing material.

Chemical Resistance

Limited resistance to certain chemicals and solvents

EPDM roofing membranes have limited resistance to certain chemicals and solvents. Exposure to substances like oil, grease, and some cleaning agents can cause the rubber material to degrade over time. It is essential to avoid contact with these substances to maintain the longevity and performance of the EPDM roof.

Prone to degradation in contact with some substances

EPDM roofs are prone to degradation when in contact with specific substances. Chemical exposure, such as prolonged contact with petroleum-based products, can cause the rubber material to break down and become less effective as a roofing barrier. Proper maintenance and avoiding contact with harmful substances are vital to prevent premature deterioration.

Color Fading

EPDM membranes may experience color fading over time

One aesthetic disadvantage of EPDM roofing is that the membranes may experience color fading over time. The black surface of EPDM roofs can gradually fade and become dull due to prolonged exposure to UV radiation, weather conditions, and other environmental factors. This color fading can give the roof a less appealing appearance.

Exposure to UV radiation accelerates this process

Exposure to UV radiation is one of the main factors that accelerate color fading on EPDM roofs. Ultraviolet rays can cause the rubber material to deteriorate and lose its original color. Therefore, it is crucial to consider this potential color change when choosing EPDM as a roofing material, especially if maintaining the roof’s aesthetic appeal is a priority.

Environmental Impact

Non-biodegradable material

A significant disadvantage of EPDM roofing is its environmental impact. EPDM is a non-biodegradable material, meaning it does not decompose naturally over time. Once the EPDM membrane reaches the end of its lifespan, it will contribute to landfill waste and take up valuable space, adding to the global waste problem.

May contribute to landfill waste

Due to its non-biodegradable nature, EPDM roofing materials may contribute to landfill waste. When the membrane needs to be replaced, the old EPDM materials cannot be easily recycled or repurposed. The disposal of EPDM roofing adds to the overall waste generated by the construction industry, highlighting the need for more sustainable roofing alternatives.

Energy-intensive manufacturing process

EPDM roofing has a significant environmental impact not only during its use but also in its manufacturing process. The production of EPDM membranes requires a considerable amount of energy, contributing to greenhouse gas emissions and resource depletion. Considering the energy-intensive manufacturing process is crucial when evaluating the overall environmental sustainability of EPDM as a roofing material.

Fire Resistance

Lower fire resistance compared to other roofing materials

EPDM roofing has lower fire resistance compared to some other roofing materials. While EPDM itself is not highly flammable, it is not as fire-resistant as materials like metal or concrete. In the event of a fire, EPDM membranes may not provide the same level of protection and can contribute to the spread of flames.

May not meet stringent fire code requirements

Depending on the specific fire code requirements in a particular area, EPDM roofing may not meet the necessary standards. Buildings located in high-risk fire zones or those with strict fire safety regulations might require roofing materials with higher fire resistance. It is essential to consult local building codes and regulations before choosing EPDM as a roofing option to ensure compliance with fire safety requirements.

Heat Retention

Absorbs and retains heat

EPDM roofing has the tendency to absorb and retain heat, which can lead to increased building cooling costs. The black color of EPDM membranes absorbs sunlight and converts it into heat energy, resulting in higher temperatures on the roof surface. This heat absorption can affect the building’s energy efficiency, as the increased heat transfer can make it more challenging to maintain a comfortable indoor temperature.

May lead to increased building cooling costs

The heat retention properties of EPDM roofing can lead to increased building cooling costs. When the roof absorbs and retains a significant amount of heat, the building’s cooling system needs to work harder to maintain a comfortable temperature indoors. This increased cooling demand can result in higher energy bills and negatively impact the building’s overall energy efficiency.

Membrane Shrinking

EPDM may shrink over time

One potential issue with EPDM roofing is membrane shrinking. Over time, the EPDM membrane may shrink, leading to issues with roof integrity and fit. As the membrane contracts, it can create gaps and expose vulnerable areas of the roof, increasing the risk of leaks and water damage.

Can cause issues with roof integrity and fit

EPDM membrane shrinking can cause significant issues with roof integrity and fit. The shrinking can create gaps between the membrane sections or between the membrane and flashing, compromising the effectiveness of the roof’s waterproofing capabilities. Proper maintenance and regular inspections are essential to identify any shrinking-related issues and address them promptly to prevent further damage.

In conclusion, while EPDM roofing has various advantages, such as durability and flexibility, it also has its fair share of disadvantages. These drawbacks include limited lifespan in certain applications, susceptibility to punctures and tears, complex and time-consuming installation process, difficulty in repairing large damages, higher initial cost compared to other roofing materials, limited resistance to certain chemicals and solvents, color fading over time, non-biodegradable nature contributing to landfill waste, energy-intensive manufacturing process, lower fire resistance, heat retention, and membrane shrinking. It is essential to consider these disadvantages and weigh them against the benefits when choosing EPDM as a roofing material for your project. Additionally, consulting with experienced roofing professionals and considering local building codes and regulations can help ensure the best decision for your specific roofing needs.